Does your company use single-use stringer pallets and dispose of them after each trip? Buying a new pallet for every load that ships isn’t sustainable economically or environmentally. While inexpensive, stringer pallets are prone to breaking, losing pieces, and shedding nails that can damage products and equipment and injure your employees. The problems associated with stringer pallets are common enough that many big box and club stores won’t accept loads shipped on them because they don’t meet basic aesthetic and safety requirements.

Instead, these stores demand that their partners ship products to them on much sturdier block pallets. These last longer and look better, but are heavier and more expensive than stringer pallets. Block pallets are intended for reuse to make the most of their durability. Reuse brings its own set of issues because it means having to return the pallets to your production centers, repair them, and clean them. Pallet pooling simplifies pallet management by taking on these responsibilities for you. The benefits of pallet pooling are simplified logistics along with a superior reusable platform for a price comparable to that of a stringer pallet.

Owning Versus Renting Pallets

The chief benefit of renting your pallets through a pooling service is that you are no longer responsible for balancing the logistics of getting your products to market against the conflicting logistics of retrieving empty pallets. The pallet pool handles this reverse supply chain for you by delivering pallets in the quantities you’ve ordered and dealing with those pallets once they’ve reached the end of the supply chain. Your company will no longer need to:

- Purchase Pallets: Acquiring a supply of stringer or block pallets is a significant expense. While the price of a single pallet is negligible, repeatedly purchasing hundreds or even thousands of them outright to maintain a supply will add up.

- Recover Pallets: Retrieving quality pallets from their final destination can be a challenge. Unlabeled block pallets in good condition will always be at risk of being lost to your retail partners or to thieves.

- Transport Pallets: Even if you can secure safe storage for your pallets at their destination, you will still have the responsibility of retrieving them, either by dispatching one of your drivers to collect them or hiring a carrier to do so for you. Companies that ship nationally will find the costs of retrieving their pallets from distant partners to be significant.

- Repair Pallets: Wood pallets are sometimes damaged by heavy equipment during normal use. Often they can be repaired, but doing so requires establishing and staffing a depot that can sort pallets by their condition to discard the ones that cannot be salvaged and repair those that can be put back into use.

- Store Pallets: Owning your pallets means having a supply large enough to handle peaks in activity. During slower periods, large numbers of empty pallets will need to be stored at your facility in a manner that complies with fire codes, insurance guidelines, and OSHA standards.

Managing a supply of reusable pallets is a business of its own–one that doesn’t directly make you money. Turning that parallel pallet business over to experts ensures that it will run to a higher standard and lowers your Total Cost of Business (TCOB).

A pooling system is also more sustainable than purchasing your own pallets. It reduces the number of trees cut to produce new pallets as well as the fuel costs used to put those pallets back into use. Since a pallet pooling provider serves many companies nationwide, it’s able to coordinate the movement of pallets in a way that’s economically and environmentally efficient. All of these benefits of pallet pooling for companies are magnified with the use of a better pallet. The iGPS plastic shipping platform is carefully built to maximize the benefits of pallet pooling far beyond what wood block pallet pooling can offer.

The Benefits of iGPS Plastic Pallet Pooling

When you choose the iGPS plastic pallet rental program, you not only gain the advantages of an experienced pallet pooling service, but you also gain the use of a superior shipping platform. The iGPS plastic pallet brings the following competitive advantages to your supply chain:

- Greater Hygiene: Plastic pallets don’t absorb moisture, chemicals, or bacteria, helping to prevent cross-contamination. The iGPS rental pallet can be easily washed, and, if required, can be completely sanitized (by a third party)

- Reduced Product Damage: The iGPS pooled plastic pallet’s consistent dimensions, top deck coverage, and absence of nails and splinters mean that the chances of product damage are significantly reduced at all points along the supply chain.

- Greater Safety: The iGPS pallet weighs around 50 pounds and can be easily moved by a single employee using built-in handholds. It is also designed with features like rounded corners that prevent snagging on product and beveled edges that help guide fork insertion to help keep your personnel working safely.

- Reduced Transport Costs: An iGPS plastic pallet is up to 27 pounds lighter than a wood block pallet, which translates into 1,300 gallons of fuel saved for every 100,000 trips. For shipments of products that weigh out, this reduced weight can allow more products to ship per truckload. For loads that cube out, iGPS rental pallets can reduce transportation costs through fuel savings.

- Reliable Automation: The uniformity of a plastic pallet allows for the precise calibration of automated palletizers, conveyor belts, and Automated Storage and Retrieval Systems (ASRS). Because plastic pallets don’t have nails or splinters that can damage equipment, switching to plastic helps ensure automated systems operate at peak efficiency with minimum downtime.

- Sustainable and Recyclable Pallet: The iGPS plastic pallet has a much longer working life than reusable wood block pallets do, and can be re-molded into a new pallet at the end of its working life. Using durable HDPE plastic ensures cradle-to-cradle sustainability that reduces wood harvesting and landfill waste.

Not only does choosing the iGPS rental pool to manage your pallets for you save you money—up to $4 per pallet load—but it also improves the efficiency of every part of your supply chain operations.

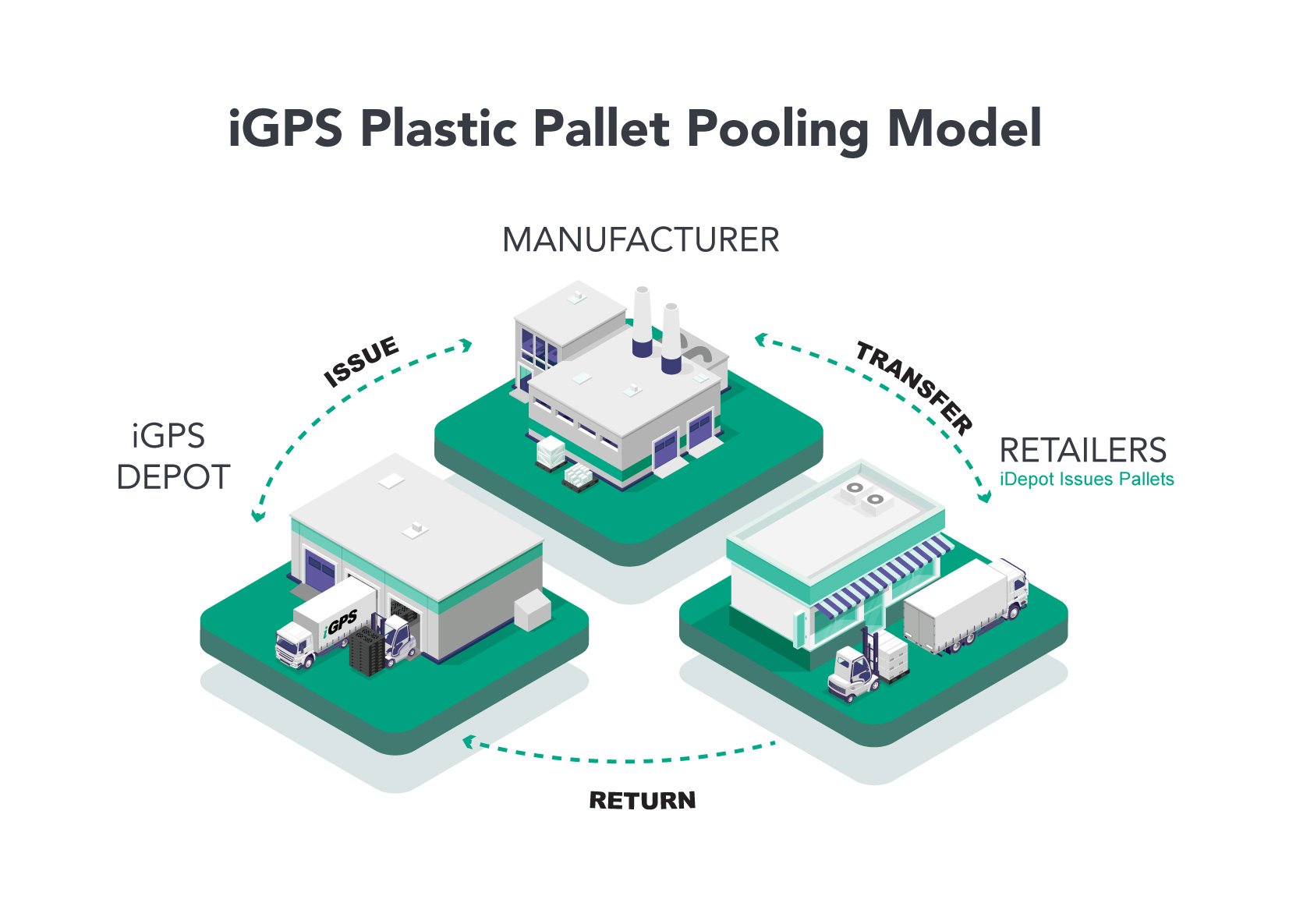

How iGPS Pallet Pooling Works for Your Business

The iGPS plastic pallet is fully compliant with Consumer Brands Association (CBA) specifications, so it’s compatible with all your existing supply chain equipment. It is tough enough to be handled by heavy equipment in the warehouse and still look good displaying ice cream cones in a club store freezer.

Only iGPS Plastic Pallets:

Are sanitary enough for bagged lettuce but strong enough for bagged concrete.

Allow you to easily track shipments through RFID technology.

Meet the highest standards of platform hygiene, according to the FDA’s Food Safety Modernization Act

Are compliant with Consumer Brand Association (CBA) specs

Once you switch to iGPS pooled plastic pallets, their lightweight, uniformity, and reliability will have a substantial and positive impact on your TCOB.