Plastic Pallet Pooling Benefits for

Bagged Produce

Nothing is better than the convenience of crisp, ripe fruits and vegetables, pre-washed and chopped. As American lives get busier and busier, more consumers than ever before are buying pre-packaged produce items. Everyone seems to love the simplicity of bagged fresh foods, from professionals looking for healthy meals they can bring to work to moms trying to encourage kids to eat more fruits and veggies with fun, single-serve packages.

While pre-cut fresh foods are in-demand with consumers, shoppers do have some concerns about food safety. Salmonella, Listeria, and E. coli outbreaks have all been traced to bagged fresh produce, particularly spinach and salad greens. Consumers want an assurance that precautions have been taken to deliver their bagged produce to grocery shelves fresh and uncontaminated. And, sustainability is also a consideration for many consumers who expect fresh food manufacturers and retailers to act consciously about the waste they produce.

Given these challenges, how can suppliers of pre-packaged fruits and vegetables meet consumer expectations while maintaining a healthy profit margin? The solution may be as simple as optimizing your supply chain with the iGPS plastic pallet pooling system.

iGPS Pallets Neutralize Bagged Fresh Food Supply Chain Obstacles

Keeping fruits and vegetables fresh until they reach the consumer is a major challenge for the produce supply chain. Bagged produce is particularly susceptible to bacterial contamination; if even a tiny particle of manure or tainted irrigation water gets into a plastic bag, the bag becomes a perfect vessel for bacterial growth. And, the processes needed to package bagged fresh food can lead to additional, unintended problems as well, such as:

Risk of Infection

Harvesting and chopping produce can create an entry point for salmonella, Listeria, and E. coli to infect fruits and vegetables.

Increased Production Expenses

The time and costs associated with packaging ready-to-eat produce raises its production expenses and can impact profit margins.

Damaging Gases

Some fruits release gases that speed the ripening process. Bagging these fruits can cause them to become spoiled or overripe as gases become trapped in the plastic bags.

Stringent CBA Standards

Using fresh food pallets that comply with precise Consumer Brands Association (CBA) specs is a federal mandate.

Excessive Waste

Not all bagged fresh food packaging can be recycled. Pre-cut fruits and vegetables often come wrapped in non-biodegradable styrofoam or plastic cellophane.

Retail Price Expectations

Lowering Total Cost of Business (TCOB) along the supply chain is necessary in order to meet consumer demand for increased convenience and quality, but lower retail prices.

Bagged fresh food is in high demand, offering manufacturers and retailers alike a market ripe with opportunity — if they can overcome some common obstacles. These products are highly perishable and susceptible to contamination. How, then, can you safely deliver fresh, unspoiled bagged produce while keeping an eye on your bottom line? The answer is iGPS.

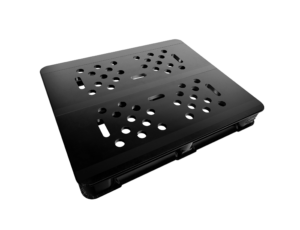

iGPS plastic pallets are designed to efficiently deliver safe, ready-to-eat produce fast. The iGPS pallet rental program is also the greenest supply chain option on the market today, proven to lower transportation emissions and eliminate wood pallet waste clogging landfills. And, by controlling logistics costs from manufacturer to retailer, you can also meet shopper price expectations without cutting into your profit margin.

The iGPS plastic pallet pooling program provides the only technology and service that can meet those goals. To get started with iGPS, reach out to our logistics experts today at 1-800-884-0225 or email us at info@igps.net. Our team will walk you through how our innovative shipping options can drastically lower your total cost of business.

Supply Chain Logistics Are in the Bag with the iGPS Plastic Pallet Pooling System

The seven top competitive advantages that the iGPS plastic pallet pooling system offers its clients are:

- Increased Food Safety and Hygiene: The iGPS plastic pallet is an ideal shipping solution for bagged fresh foods as it’s impeccably clean. Given the fact that bagged produce is susceptible to bacterial contamination and foreign objects entering their product, supply chain operators must eliminate every opportunity for contamination possible. Easy to clean, our pallets are capable of withstanding both extreme water temperatures and high pressure. iGPS plastic pallets do not have sharp edges or nails that can puncture packaging, or worse, get within the bagged product. And, only iGPS sterile pallets are made of a material that’s impervious to insects and rodents. They will not rot or absorb moisture, and they effectively resist bacteria. Our bagged produce shipping pallets meet or exceed all FDA and FSMA food safety and hygiene requirements.

- Reduced Transportation Costs: Bagged produce must arrive to retailers as quickly as possible to avoid the common and expensive pitfalls of delayed transit: spoilage, dehydration, loss of vitamins, wilting, and lack of crispness. An efficient supply chain is a boon to your bottom line. Weighing up to 35% less than the average wooden platform at around 50 pounds, the iGPS sterile food-grade pallet delivers shipments faster, for less. Our plastic pallets reduce total load weights, thus lowering fuel costs.

- Minimal Product Damage: The iGPS pallet can stand up to the cold shipments needed to keep bagged produce fresh. Our plastic pallets don’t crack or shatter under the cold temperature of ice—or its heavy weight. Each FSMA plastic pallet is reinforced for exceptional strength and guaranteed to maintain its size and dimensions, eliminating damaged packages due to splintered wood.

- Exceptional Automation Abilities: iGPS pallets are guaranteed to flow smoothly through automated systems, thus reducing downtime and improving overall production. This feature makes it great for retailers and manufacturers who have invested in automated warehouse stock retrieval (AWSR) systems that require automated guided vehicle (AGVs) compliant pallets.

- Unsurpassed Sustainability: Bagged food producers are under pressure to reduce waste as much as possible. One way of doing this is by reusing plastic pallets, instead of contributing to the solid waste of wood pallets filling up landfills. iGPS vegetable food grade pallets are a “cradle to cradle” solution. If a pallet is damaged, it can be recycled into a new one. And, because plastic pallets are lighter than wooden ones, less fuel is required for transportation, which reduces carbon emissions. To estimate the amount of carbon emissions the iGPS pallet can reduce for each of your shipments, try using our greenhouse gas calculator.

- Industry-Leading Worker Safety: iGPS fruit food-grade pallets are lighter and easier to move than wood pallets, increasing worker safety. This is especially helpful when moving pallets throughout the field or the warehouse with or without product on them. Our plastic pallets reduce the chance of injury caused by traditional wooden platforms by being lighter weight to lift, eliminating pallet failures, and doing away with protruding nails and splinters.

- A Highly Efficient Pooling System: By renting pre-packed fruit and veg pallets rather than buying them, you get the exact number of pallets you need, when you need them. Pooling eliminates the expense of purchasing and maintaining a pallet inventory as extra pallets require valuable and costly storage space during periods of low demand.

Offering consumers the food safety, sustainability, and competitive prices they demand is easy with the iGPS plastic pallet pooling solution. iGPS pallets ensure that both you and your customers can trust that bagged produce stays safe from contaminants while en route to grocery shelves. With the cost-cutting benefits of greater hygiene, faster deliveries, reduced product damage, and lower transport logistics costs, your supply chain is no longer one of your greatest liabilities—it is now your greatest asset.

The iGPS Pallet Pooling System Delivers for You and Your Loyal Customers

Don’t struggle with the many daunting challenges and consumer demands placed on the bagged fresh produce industry. Solve them using iGPS plastic pallet pooling.

The iGPS pallet pooling program enables you to focus on capital expenditures and day-to-day supply chain operations. iGPS delivers quality pallets, on time, as required by the manufacturer. After the manufacturer ships their products to their distributors and the pallets have been unloaded at a retail outlet, the iGPS team arranges for the empty pallets to be returned to one of their many depots throughout North America for inspection, cleaning, and, if required, repair. They are then reissued to another manufacturing customer.

Seamless, easy, and cost-effective, the iGPS pallet pooling program ensures that operations run smoothly for everyone who handles pre-cut and packaged produce products. iGPS is the shipping logistics solution that makes your supply chain more efficient, effectively lowering your TCOB without impacting quality. When you can achieve greater savings along the supply chain, you can also meet one of the top consumer demands: lower prices.

iGPS Plastic Pallets

Are sanitary enough for bagged lettuce but strong enough for bagged concrete.

Allow you to easily track shipments through RFID technology.

Meet the highest standards of platform hygiene, according to the FDA’s Food Safety Modernization Act.

Are compliant with Consumer Brand Association (CBA) specs.

With iGPS on your side, they never have to question the safety of their favorite fruit and veggie products—and neither do you.