Plastic pallet pooling means sharing durable plastic pallets among multiple users, reducing costs and environmental impact. Similar to the efficiencies realized by carpooling, pallets are rented and shared between multiple companies in the same region for more efficient use and reduction in transport.

Pallet pooling improves logistics, reduces storage needs, and enhances sustainability. Users benefit from lower costs and the availability of consistent, high-quality pallets for transportation and storage.

What Is a Plastic Pallet

A plastic pallet is a flat platform made from durable plastic, used for transporting, storing, and handling goods. Unlike wooden pallets, plastic pallets are resistant to moisture, chemicals, and pests, making them ideal for hygienic environments.

They are reusable, lightweight, and often designed to be stackable and nestable, improving storage efficiency and reducing shipping costs.

Read more: Plastic Pallets: Your Definitive Guide

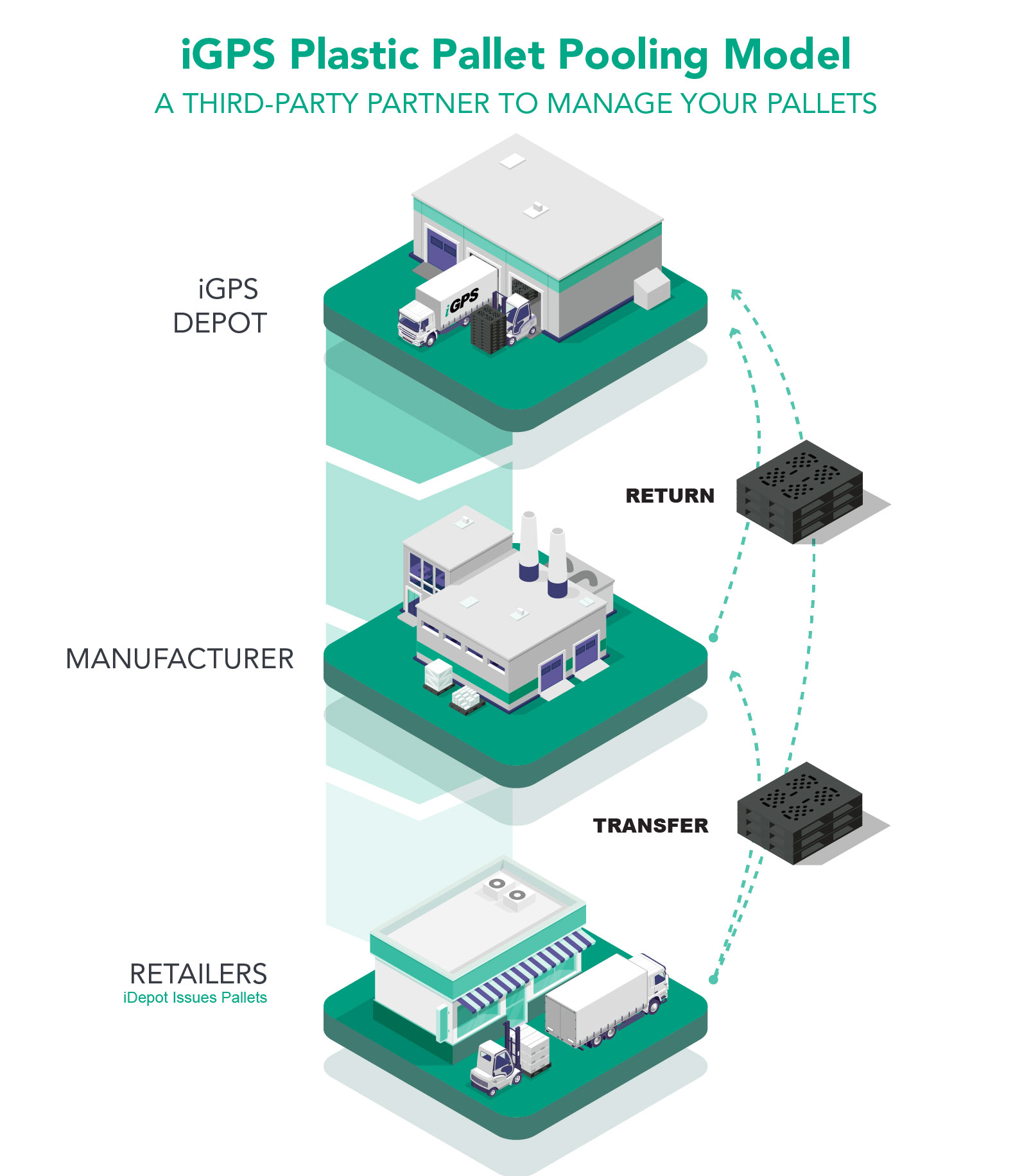

How Does Pallet Pooling Work

Pallet pooling works by providing shared pallets to multiple companies. Users rent pallets instead of owning them.

iGPS Logistics is the largest plastic pallet pooling provider in North America and manages the supply, maintenance, and quality of their pallets. When your company needs pallets, iGPS sends exactly what you need from its closest depot. After use, pallets are returned, inspected, and repaired if necessary before being redistributed.

Benefits of Plastic Pallets

Plastic pallets provide numerous advantages:

- Durability: These pallets resist breakage and can handle heavy loads, ensuring long-term use.

- Hygiene: They are easy to clean and maintain, preventing contamination and meeting high sanitation standards.

- Longevity: Plastic pallets last four times longer than wood, reducing the need for frequent replacements and lowering overall costs.

- Lightweight: They are up to 35% lighter than wood block pallets, which helps reduce shipping expenses and makes manual handling safer.

- Consistency: Their uniform size and shape ensure smooth operations in automated systems and storage.

- Recyclable: 100% recyclability makes plastic a true circular product, contributing positively to sustainability efforts.

- Safety: Because plastic pallets have no nails or splinters, they reduce the risk of injuries during handling and use.

Benefits of Pallet Pooling

Pallet pooling is used by many manufacturers and logistic companies looking to reduce logistics costs and improve their sustainability efforts. Pallet pooling has numerous benefits:

- Cost Efficiency: Renting pallets reduces the need for purchasing and maintaining an individual stock, lowering overall costs.

- Sustainability: Shared use reduces waste and promotes recycling, supporting environmental initiatives.

- Quality Assurance: The pallet pooling provider maintains all pallets, ensuring high-quality and consistent performance.

- Flexibility: Companies can scale their pallet needs up or down based on demand, improving operational flexibility.

- Space Saving: Pooling eliminates the need for large storage areas for pallets, freeing up valuable space.

- Streamlined Logistics: Centralized management of pallets enhances supply chain efficiency and reliability.

- Reduced Liability: The pooling provider takes responsibility for pallet maintenance, reducing liability for users.

Read more: Benefits of Pallet Pooling

FAQ on Plastic Pallet Pooling

What is a pooled pallet?

A pooled pallet is a reusable pallet shared among multiple companies through a rental system. Managed by a company like iGPS, these pallets are circulated, maintained, and redistributed as needed, reducing costs and promoting sustainability. Your company benefits from consistent access to high-quality pallets without the need for ownership or extensive storage.

Can you stack plastic pallets?

Yes, plastic pallets can be stacked. Their design allows for efficient stacking, saving storage space and improving transportation efficiency. Stacked plastic pallets provide stability and help optimize warehouse organization.

What is the OSHA standard for stacking pallets?

OSHA’s standard for stacking pallets requires stability and safety. Pallets should be stacked evenly, not exceeding a height of fifteen feet (four if handled manually) and should not create hazards by blocking exits or obstructing aisles. Regular inspections ensure compliance and prevent accidents.