Plastic Pallet Pooling Benefits for

Paper Goods

Where would the world be without paper? Paper doesn’t only provide us with a handy surface to write, draw, or color on, it also helps prevent the spread of illness and makes cleaning ourselves and our homes easy. Paper towels, facial tissue, toilet paper, baby diapers, personal wipes, and many more paper items are universal in our homes and those of our customers. For this reason, the paper goods industry is fast-moving; toilet paper may be able to sit in a distribution center without spoiling, but, chances are, it won’t have to. It’s a consumable product that’s in constant use and demand.

Getting paper products safely to the grocery and retail stores at the end of the paper manufacturing supply chain means avoiding damage by moisture, debris, and inattentive handling. Being able to stock shelves with intact products is crucial, both for manufacturers who can’t afford the cost of wasted paper goods and for the retailer who must offer consistent quality and quantity to the consumer. Rental of iGPS’ hygienic, safe plastic pallets can help paper product manufacturers and retailers meet these challenges with less product damage and less risk of contamination, helping to reduce their Total Cost of Business (TCOB).

Overcoming Paper Manufacturing Supply Chain Challenges with the iGPS Plastic Pallet

Moving absorbent, hygienic paper products through loading docks, industrial areas, and trailers while keeping them safe and dry isn’t easy. Paper products are especially susceptible to certain kinds of damage.

Packaging Damage

If the packaging of a paper product is damaged during storage or transportation, consumers will leave the product on the shelf, no matter how minor the damage may be. After all, many of these products are used to keep homes and bodies clean, and many will come in contact with children’s skin, making intact packaging a special concern for consumers. Damage to paper product packaging often comes about through contact with the broken edges, rough surfaces, splinters, and protruding nails of wood shipping pallets.

Large Cubic Volume

Packaged paper products typically do not weigh a lot; instead, they take up a large cubic volume of space. Finding ways to maximize the amount of paper product that fits onto standard-sized shipping pallets and into trailers can be a challenge for suppliers. Poorly maximized space reduces efficiency and can result in crushed products, which will also be left on the shelf by consumers.

Moisture Intrusion

Not only will moisture damage paper products and make them ineffective, it can also create an environment suitable for microbial growth. Wood pallets open up opportunities for moisture damage to paper products because of their porous, absorptive nature.

High Throughput

The demand for paper products is constant. In addition to taking up a large amount of volume, paper products also require high levels of throughput to meet demand. Meeting consumer demand with safe, sanitary, and ready-to-use paper products is the greatest challenge for the paper manufacturing supply chain and the retailer.

Consumers looking for paper products are picky, and rightfully so. These products will be the napkins on their tables, the paper towels that clean their bathrooms, and the diapers that keep their children dry at night. Maximizing profits while providing customers with the best paper goods means keeping products undamaged and sanitary during transportation and storage.

Renting the iGPS plastic pallet can help your company deliver more packaged paper products with less product damage, reducing your Total Cost of Business and maximizing profits in your existing supply chain. To get started with iGPS, reach out to our logistics experts today at 1-800-884-0225 or email us at info@igps.net.

Why the iGPS Plastic Pallet Pool is the Right Fit for the Paper Goods Industry

- Exceptional Sanitation: The pristine nature of freshly wrapped paper products straight from the mill has to be preserved to ensure customer satisfaction. The iGPS plastic pallet is non-absorbent and does not hold moisture that can encourage the growth of bacteria, fungi, and other microbes. With plastic pallets, paper products arrive dry and hygienic.

- Reduced Fuel Costs: The iGPS plastic pallet weighs around 50 pounds, making it much lighter than a typical 65-75 pound wood block pallet. Reducing the weight of your pallets will significantly reduce the overall weight of your truckloads, saving on the fuel costs of the frequent shipments needed to meet demand.

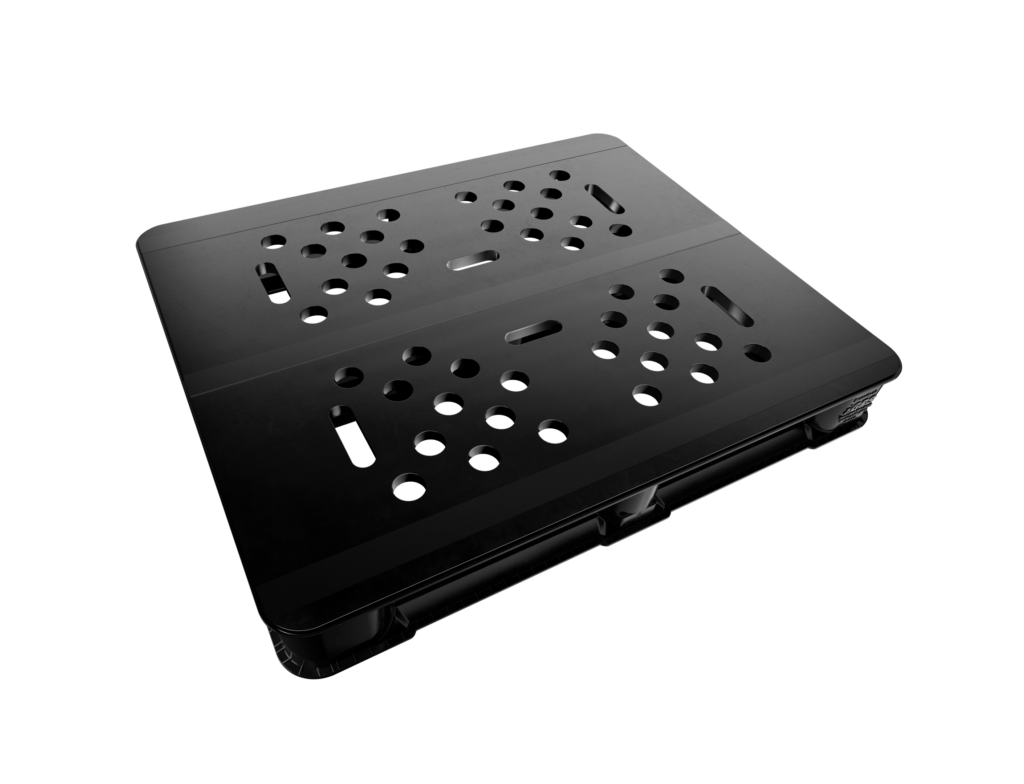

- Increased Product Safety: The iGPS plastic pallet has a unitized construction without nails or splinters that can snag product packaging. Unlike wood pallets, plastic pallets aren’t absorbent, so they don’t retain moisture that can later seep through packaging to contaminate the product within.

- Improved Automation: Meeting the heavy demand for paper products may require high-speed machinery like Automated Storage and Retrieval Systems (ASRS) and Automated Guided Vehicles (AGVs). The iGPS pallet has uniform dimensions and consistent weight, making it better suited for use with automated systems than wood pallets. The consistency of plastic pallets prevents interruptions in automation and allows your automated systems to work at full capacity to meet demand.

- Greater Sustainability: The iGPS plastic pallet is capable of making 100+ trips through the supply chain; four or more times as many trips as reusable wood pallets. This allows fewer new pallets to enter the supply chain each year and reduces the amount of timber harvested for wood pallets. At the end of their lifespan, iGPS plastic pallets are reground and recycled directly into new plastic pallets. It’s true cradle-to-cradle recycling, and you can see how much it reduces carbon on each shipment with our greenhouse gas calculator.

- A Safer Environment for Workers: Injuries are commonplace in warehouses even with lightweight products like paper goods. Wood pallets are heavy, and moving or stacking them by hand can cause sprains and strains. The light weight of iGPS pallets makes them safer when handled manually and their smooth plastic surface eliminates dangerous broken boards, nails, and splinters.

- Efficient Nationwide Pooling: A pallet rental pool allows you to focus on the business of manufacturing, selling, and transporting paper goods instead of purchasing new pallets, repairing them, and managing a pallet inventory. The network of pallet depots managed by iGPS stretches across North America and can provide superior plastic pallets when and where you need them 24/7.

iGPS Plastic Pallet Pooling Improves Profit Margins on Your Paper Goods

In the high-traffic paper goods market, interruptions that bring the paper manufacturing supply chain to a stop are expensive. The iGPS plastic pallet is a reliable shipping platform that reduces these interruptions, saving you time, preventing accidental damage, reducing your TCOB, and protecting your profit margins. It’s time to future-proof your paper manufacturing supply chain with the sustainable, durable, and reliable iGPS plastic pallet.

Supports integrating their pallet with your warehouse automation

iGPS plastic pallets meet the highest standards of platform hygiene, according to the FDA’s Food Safety Modernization Act

iGPS plastic pallets meet all Consumer Brand Association (CBA) specifications