Plastic Pallet Pooling Benefits for

Water & Beverage

Bottled water has become an extremely popular beverage over the past decade. This revolutionary product has made clean drinking water easy to distribute, carry, and enjoy—even in remote areas where clean running water is inaccessible. And, with a range of new water-based beverages becoming popularized, such as flavored and carbonated water, consumers have more ways to stay hydrated than ever before.

Selling beverages sounds easy—but it isn’t. There’s far more to the success of the industry than simply filling bottles. Beverage products source components from around the world. Producing bottled water, for instance, can involve shipping materials and components across multiple continents; the bottle caps may be manufactured in Taiwan, while the paper labels come from New Zealand. A bottled or canned beverage and its packaging may travel around the Pacific Ocean, and then still need to be delivered to distributors and retailers throughout North America, from West Coast to East Coast.

Global supply chains for the bottled water and beverage industry are lengthy and complex. The success of this industry relies on partners to help them lower their Total Cost of Business (TCOB) by increasing the efficiency of their supply chain. iGPS is a knowledgeable logistics solution provider with the experience needed to help your beverage business optimize its supply chain—regardless of how far around the world it extends.

The Bottled Water Journey

The bottled beverage and water industry is a complicated one, despite delivering a seemingly simple good to consumers. For bottled water, in particular, the water purification process involves many steps before the product can even be introduced to the global supply chain, and even spring water must be trucked in before it is bottled.

These are some of the top obstacles for the bottled beverage and water industry include.

A Global Supply Chain

Global supply chains have many pain points to overcome. With so many participants in a variety of distant locations, logistics management and communication must be optimized or risk becoming a major liability.

CBA Compliance Expectations

Bottled and flavored water must be shipped using strict standards that meet Consumer Brands Association (CBA) compliant food grade water pallet standards.

Heavy Product Loads

Bottled beverages are not light. Moving heavy shipments over long distances drives up fuel and transportation costs. And, heavy shipments can be difficult for workers to move. In fact, beverage shipments can become too heavy for wood pallets to carry, requiring heavy-duty, reinforced plastic pallets.

Automated Systems that Require Uniformity

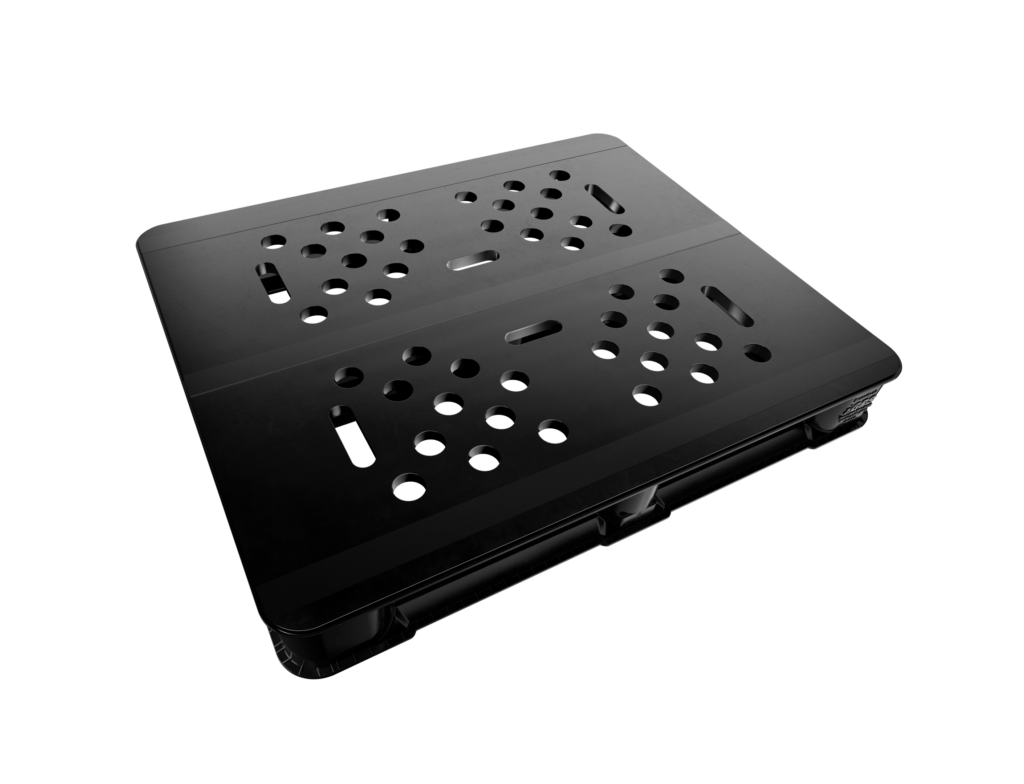

Distribution centers and warehouses are increasingly using Automated Storage and Retrieval Systems (ASRS) to help streamline and manage inventory. These systems require pallets to maintain a consistent size and shape. A misshapen or broken wood pallet can shut down a multi-million dollar automated system, creating high direct costs and significant collateral damage caused by spilling product over neighboring inventory, as well as significant human risk.

Unavoidable Waste Byproducts

The beverage industry, particularly bottled water companies, are seen as the responsible parties for an upsurge in plastic waste. When consumers hear about landfills and waterways clogged with plastic bottles that should have been recycled, they look to the beverage industry, not their neighbors, as the problem’s source. Manufacturers must make their supply chains as sustainable as possible in order to offset this dilemma.

Total Cost of Business Concerns

Consumers demand ever lower prices. Total Cost of Business (TCOB) must remain low in order for a beverage business to stay competitive. Increased efficiencies and the use of an intelligent pallet pooling system that does not waste transportation resources can help bring down your company’s TCOB.

If your water or beverage business is facing these challenges, choose a logistics technology service that can offer your supply chain a competitive edge. iGPS plastic pallets are sturdy enough to go the distance of your ever-lengthening supply chain, ensuring reliable deliveries consumers can count on. And, our pallet pooling system means you get a holistic solution that lowers costs by making your supply chain more efficient, flexible, and secure.

To get started with iGPS, reach out to our logistics experts today at 1-800-884-0225 or email us at info@igps.net. Our team will walk you through how our innovative shipping options can drastically lower your total cost of business.

Why the iGPS Plastic Pallet Competitive Advantages Bottle Up the Competition

The iGPS plastic pallet pooling system empowers logistics managers, making your supply chain more efficient and easier to manage, while simultaneously lowering your TCOB. The seven top competitive advantages of the iGPS plastic pallet include:

- Increased Safety and Hygiene: The pallets that beverage and bottled water shipments travel on affect the hygiene of the product being shipped. Only the iGPS plastic pallet is impervious to insects and rodents, does not rot or absorb moisture, and is highly resistant to bacteria.

- Lower Transportation Costs: Global supply chains, such as those in the water and beverage industry, must make the best possible use of their transportation assets if they wish to remain competitive. iGPS plastic pallets are up to 35% lighter than standard wood pallets. Weighing around 50 pounds, iGPS plastic pallets reduce your shipments’ total weights. The result is lower fuel costs to transport your products from the warehouse to the retailer. Any element that lightens liquid loads can have a significant impact on your bottom line. Lighter loads also mean faster delivery in order to meet retailer and consumer demands.

- Reduced Product Damage: The iGPS plastic pallet is sturdy, uniform, and has no protruding edges or parts, reducing product damage. If beverage containers become damaged during transit, supply chain operators can have a giant liquid mess on their hands, as well as a loss in revenue.

- Reliable Automation Capabilities: As warehousing systems continue to become increasingly automated, all pallets must adhere to consistent physical parameters. The iGPS plastic pallet is ideal for automated stock retrieval systems (ASRS) as each one is a uniform 48 x 40 inches. Their uniform design will not cause errors in automated systems, creating a higher level of engineering reliability that is just not achievable using older wood pool pallets. iGPS plastic pallets do away with the unwanted product overhang that’s caused when wood pallets have broken leading edge boards. Shrinkage and warping are also not a concern with iGPS food grade pallets, ensuring compatibility with automated guided vehicle (AGV) technology. Simply put, with iGPS, pallet problems are no longer an issue, particularly for iGPS customers using automated production and handling systems.

- Industry-Leading Sustainability: Beverage companies must make sustainable decisions, as mandated by the public. iGPS plastic pallets eliminate the need for wood platforms, thereby reducing the consumption of trees. When iGPS plastic pallets reach the end of their life cycle, they are recycled to create new pallets, a “cradle to cradle” solution where pallets are produced and recycled responsibly. Our hygienic beverage pallets are reusable, long-lasting, and require less fuel. Using iGPS pallets also means fewer truck movements. The fact that iGPS pallets have such a low percentage of damage at the end of their working cycle means more pallets can be reissued direct from retailers rather than being transported back to a wood pooler’s depot to be repaired. This reduces the amount of trips the pallets must make, which, in turn, significantly reduces carbon emissions during transit. To estimate the amount of carbon emissions the iGPS pallet can reduce for each of your shipments, try our greenhouse gas calculator.

- Superior Worker Safety: Loads of heavy beverages can be difficult for workers to negotiate and handle. The iGPS plastic pallet is not only safer for employees to work with than wood pallets, but also makes handling pallets easier; a single employee can lift an empty pallet. Durable plastic also eliminates broken boards, protruding nails, and splinters that can injure warehouse workers.

- An Efficient Pooling System: Pallet pooling allows the bottled and canned beverage and water industry to better manage global supply chains, enabling a focus on capital expenditures and day-to-day operations. By renting pallets rather than buying them, you get the exact number of pallets you need, when you need them, which eliminates the expense of purchasing, maintaining, and warehousing a pallet inventory. Pooling means pallets are efficiently allocated and routed to maximize both usage and transportation resources.

iGPS meets its deadlines, giving retailers the stock then need when they need it. Our plastic pallet pooling system accomplishes this using sophisticated planning. After the manufacturer ships their products to their distributors and they have been unloaded at a retail outlet, the iGPS plastic pallets are returned to one of the many North American iGPS depots. There the pallets are inspected, cleaned, and maintained—ready to be sent out to the next manufacturing customer.

iGPS Plastic Pallets:

Are sanitary enough for bagged lettuce but strong enough for bagged concrete.

Allow you to easily track shipments through RFID technology.

Meet the highest standards of platform hygiene, according to the FDA’s Food Safety Modernization Act.

Are compliant with Consumer Brand Association (CBA) specs.