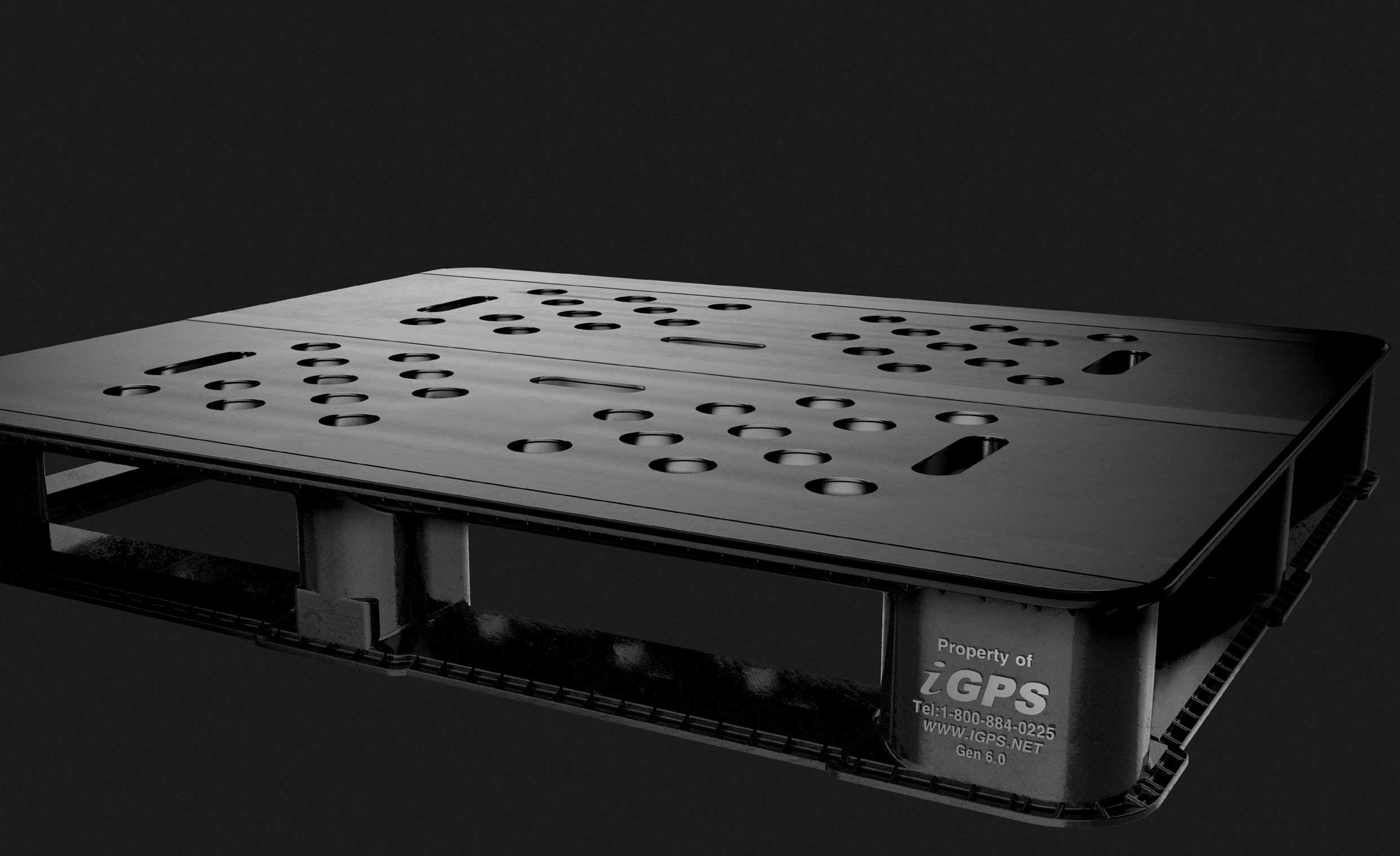

| Pallet Specifications | Gen 1 | Gen 3 | Gen 6 |

|---|---|---|---|

| Top Deck Dimensions(6) | 47.8″ X 39.5″ | 48″ X 40″ | 48″ x 40″ |

| Bottom Deck Dimensions(6) | 47.5″ X 39.5″ | 48″ X 40″ | 48″ X 40″ |

| True 48″ x 40″ (Top/Bottom)(6) | No | Yes | Yes |

| Available Space Inside Lips | 47.25″ X 39.25″ | N/A | N/A |

| Pallet Height | 5.62″ | 5.62″ | 5.62″ |

| Fork Opening 40″ Side | 3.5″ X 12.5″ | 3.4″ X 14.25″ | 3.73″ X 12.2″ |

| Fork Opening 48″ Side | 3.5″ X 14.7″ | 3.4″ X 14.62″ | 3.71″ X 14.2″ |

| Weight | 48.5 lbs | 50 – 54 lbs | ~50 lbs. |

| % Top Deck Coverage | 95% | 87% * | 88% |

| Static Load Capacity (evenly distributed) | 30,000 lbs | 30,000 lbs | 30,000 lbs |

| Dynamic Load Capacity (evenly distributed) | 5,000 lbs | 5,000 lbs | 5,000 lbs |

| Rack Load (evenly distributed) | 2,800 lbs (Min. support of 2″ on both rails) | 2,800 lbs (Min. support of 2″ on both rails) | 2,800 lbs (Min. support of 2″ on both rails) |

| Fire Performance* | UL 2335 & FM 4996(1) | UL 2335(2 to 4) | Testing |

| RFID | Yes | Yes | Yes |

| Barcode | Yes | Yes | Yes |

| Material | HDPE | HDPE | HDPE |

| Repairable | Yes | Yes | Yes |

| Repair Type | Screws | Snap In | Weld |

| Temperature Range | -20 F to 140 F | -20 F to 140 F | -20 F to 140 F |

| ISO 8611-3 | Yes | Yes | Yes |

| CBA Standards (formerly GMA) | Yes | Yes | Yes |

| ISPM (International Standard for Phytosanitary Measures) | Exempt | Exempt | Exempt |

| Nesting Ability | Yes | Yes | Yes |

*The iGPS fleet of pallets consists of pallets that have been certified by UL and FM or UL only, and a portion that has not due to ongoing R&D and durability testing. Specific pallets that have been certified are listed below.

(1)Gen 1 pallets (manufactured by Schoeller Arca Systems Inc.) received UL 2335 listing on July 20, 2007 and FM Approvals 4996 listing BiPP4840 HR 6R on September 8, 2008 to September 25, 2012.

(2)Gen 3.5 pallets received UL 2335 listing on October 26, 2016.

(3)Gen 3.6 & 3.6.3 pallets received UL 2335 listing on November 2, 2017.

(4)Gen 4.0 pallets received UL 2335 listing on November 2, 2017.

(5)Due to the effects of thermal expansion and contraction, and deviations in the manufacturing process, all dimensions and weight are approximate.

(6)All Gen 1 pallets manufactured between March 2010 and September 2012 received NSF certification for this timeframe.

Notes: Use conditions vary by loading method, prevailing temperature, and length of storage time. Static Load: Compression strength on a level floor with a uniformly distributed load at a room temperature of ~70 °F. Racking Load: Uniformly distributed load along the longitudinal sides, resting on two supports of two inches or more in width along the entire longitudinal side. iGPS recommends testing any pallet proposed in the application prior to implementing the full system. Dynamic Load: On the fork with uniformly distributed load at ambient temperature of ~70 °F. Capacity is dependent upon application and use environment. Elevated temperatures and concentrated loads can affect capacity. Customers should check with iGPS for suitability in their applications. Customers are required to validate for themselves the suitability of iGPS Pallets for their particular application. Some applications may require additional support by underpinning, appropriately placed crossbars, or mesh. Because each application is unique, customers assume all risks associated with their actual use of iGPS pallets.

Download our Pallet Spec Sheet Here

All pallet types are considered homogenous for use in open pooling; therefore, pallet orders are fulfilled with mixed loads, unless otherwise requested, and are subject to sortation fees.