Plastic Pallet Pooling Benefits for

Canned Goods

What good is a salad without dressing? A sirloin without steak sauce? Milk without cookies? Consumers insist on variety and convenience. It’s up to manufacturers and retailers to offer the sides, sauces, and seasonings that complete a meal, from peanut butter to jelly, croutons to dried cranberries. And, to top it off, no matter how high-quality your products are, consumers always want greater savings.

The grocery supply chain continually wrestles with tight margins and inflating customer expectations. But increasing profit margins is possible—if you focus on raising efficiency with the right technology, shipping supplies, and service partners.

Cut costs, not quality. Upgrade your inefficient supply chain to the iGPS plastic pallet pooling system. Our pallet pooling services lower your total cost of business (TCOB), which benefits your bottom line. And that means both you and your customers get a great deal.

iGPS Plastic Pallets Eliminate Grocery Supply Chain Challenges

It’s a hard market for grocery manufacturers and retailers. The competition is fierce and still growing, with groceries now available through nontraditional sources like online retailers. As new competitors enter and shift the market, manufacturers and retailers must be ready to optimize their supply chain logistics in order to face the competition head on.

Heavy Loads that Tax Wood Pallets

Canned goods are heavy. Shipping them requires sturdy canned food pallets that won’t buckle, break, or warp under the weight.

Sustainability is a Top Priority

The supply chain must be sustainable, especially as grocery shipments are heavy and expensive to ship. The level of carbon emissions per shipment must be lowered whenever possible. Additionally, used and broken wood pallets are increasingly clogging landfills, creating solid waste.

Hygiene is Crucial

Dry goods, such as grains, bread, and pasta, must meet or exceed all U.S. Food and Drug Administration (FDA) and Food Safety Modernization Act (FSMA) standards.

CBA Compliance is a Must

Supply chains are required to use grocery shipping pallets that comply with Consumer Brands Association (CBA) specs.

Wood Increases Contaminant Exposure

Wood pallets are porous and absorb liquids, which makes them susceptible to bacteria such as E. coli and Salmonella that can contaminate grocery products during transit. Wood also attracts insects, increasing the risk of exposure to environmental contaminants, particularly if a package is damaged due to a splintered wooden platform.

Automated Systems Require Uniformity

Automated warehouse retrieval systems, used frequently in grocery product supply chains, require pallets to be consistently uniform in size, weight, and dimensions. A misshapen or broken wood pallet can be responsible for shutting down a multi-million dollar automated system.

Climate Control is Critical

If dry goods are exposed to moisture and humidity during transit, they can become contaminated with fungal spores.

The general grocery foods market has a slight profit margin to begin with, and consumers demand ever-lower prices. Total Cost of Business, or TCOB, must be lowered by addressing the common obstacles listed above. Meeting these challenges, one by one, requires a cutting-edge logistics solution created by shipping industry experts. Grocery manufacturers and retailers alike need pallet pooling services that make the supply chain more efficient, lower their TCOB, and create cost savings that can be passed on to consumers – all without hurting food safety standards.

The iGPS plastic pallet pooling program provides the only technology and service that can meet those goals. To get started with iGPS, reach out to our logistics experts today at 1-800-884-0225 or email us at info@igps.net. Our team will walk you through how our innovative shipping options can drastically lower your total cost of business.

iGPS Offers Competitive Advantages and Logistics Solutions

The seven top competitive advantages that the iGPS plastic pallet pooling system offers its clients are:

- Unprecedented Food Safety and Hygiene: iGPS plastic pallets increase hygiene by reducing product damage during transit, thereby minimizing exposure to food contaminants. The iGPS plastic pallet is made of a material impervious to insects and rodents, which does not rot or absorb moisture, and resists bacteria. You will never need to subject an iGPS food-grade pallet to fumigation or pesticides. And, our pallets meet or exceed all FDA and FSMA food safety and hygiene requirements.

- Decreased Transportation Costs: Canned goods or jarred liquids can add up to heavy loads. At around 50 pounds, iGPS plastic pallets weigh up to 35% less than the average wood block platform. This advantage reduces total load weights and lowers fuel costs.

- Reduced Product Damage: Each pallet is guaranteed to maintain its size and dimensions; unlike wood pallets, they will not splinter, have protruding nails, or develop sharp edges. This means your packaging will not get snagged, torn, or punctured during transit, which can lead to product exposure.

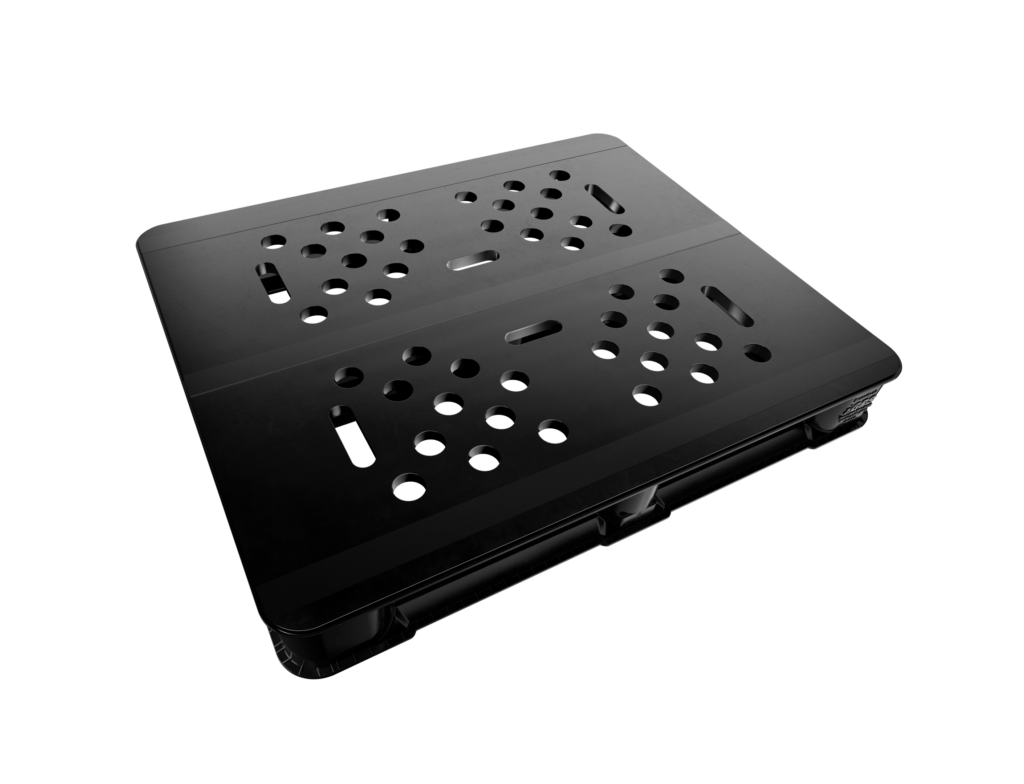

- Increased Automation: iGPS pallets scan smoothly through automated warehouse stock retrieval (ASRS) systems because each pallet is the same weight and 48 x 40-inch dimensions. This uniformity makes our pallets an excellent value-add for retailers and manufacturers who have invested in automated systems and need compliant pallets that work seamlessly with automated guided vehicles (AGVs).

- Greater Sustainability: Consumers love a neighborhood grocer that focuses on sustainable practices. Deliver on your promise of offering sustainable groceries with the iGPS pallet. It’s a “cradle to cradle” solution: if a pallet is damaged, it can be recycled into a new one. Wooden pallets have a finite lifespan that ends in a landfill as solid waste. Additionally, because plastic pallets are lighter and lower fuel requirements, carbon emissions are also reduced. To estimate the amount of carbon emissions the iGPS pallet can reduce for each of your shipments, try using our greenhouse gas calculator.

- Increased Worker Safety: Worker safety is always a high priority any time you are dealing with heavy freight. Our plastic pallets help you increase workplace safety by reducing the chance of injury caused by traditional wood pallets. iGPS plastic pallets have no gaps, broken boards, protruding nails, or splinters. And, because they’re lighter, they’re safer and easier to move and lift.

- Superior Pooling Efficiency: By renting pallets rather than buying them, you have at your disposal the exact number of quality pallets you need, when you need them. Pooling also eliminates the expense of purchasing, maintaining, and managing a pallet inventory; extra pallets take up valuable and costly storage space during periods of low demand.

A Holistic Shipping Logistics Solution

Shoppers rely on canned, dry, and packaged foods just as heavily as they do the meat, dairy, and produce stocked around the supermarket’s perimeter. They turn to these convenient food options to complete their meals and provide tasty snacks. To provide this wide selection of sides, seasonings, and ready-to-eat products while keeping costs low, manufacturers and retailers must invest in the logistics solution that solves all of the supply chain’s major pain points: the iGPS plastic pallet pooling system.

Only iGPS intelligent pallet pooling can increase your supply chain’s levels of efficiency, food safety, and sustainability by optimizing how warehouse and transportation assets are used. The iGPS pooling system delivers quality plastic pallets, on time, as required by the manufacturer. Once the pallets have been unloaded at a retail outlet, iGPS arranges for the return of the empty pallets back to one of their many depots throughout North America for inspection, cleaning, and, if required, repair. They are then reissued to another manufacturing customer. The system is easy, cost-effective, and makes operations run more smoothly for supply chain operators.

Only iGPS Plastic Pallets

Are sanitary enough for bagged lettuce but strong enough for bagged concrete.

Allow you to easily track shipments through RFID technology.

Meet the highest standards of platform hygiene, according to the FDA’s Food Safety Modernization Act.

Are compliant with Consumer Brand Association (CBA) specs.

Consumers want aisles of product options when it comes to their groceries; it can be hard to find a shipping solution that can accommodate them all – and their unique packaging challenges. With the iGPS plastic pallet pooling system, you can give consumers the wide selection they want at the low prices – and high quality – they demand.