Plastic Pallet Pooling Benefits for

Health & Wellness

Whether you manufacture nutraceuticals and natural wellness supplements, CBD products, or cosmetics and beauty brands, your business is focused on making your customers’ lives better, happier, and healthier. But building a nationwide supply chain that is as ethical, safe, and effective as your brand can be challenging.

Is there a supply chain solution that aligns not only with the regulatory requirements, but also with the ethical and sustainability practices the health and wellness sector demands? The answer is yes. The answer is the iGPS plastic pallet pooling system.

Lifting the Spirit: Leveraging Innovation to Ship Health & Wellness Products

iGPS’ 100% recyclable, and sustainable plastic rental pallets with embedded radio frequency identification (RFID) tags help to create a greener more innovative supply chain. Our pallet solution not only reduces your carbon footprint and your total cost of business (TCOB), but it also meets the demands and requirements of the health and wellness industry.

Lower Cost

Save up to $4 per pallet load by switching from conventional wood block pallets.

Safer Design

Sturdy, uniform design with no splinters or nails to damage products or cause injuries.

Reduce Emissions

iGPS’ lightweight, recyclable pallets have 30% less impact on global warming.

Improve Automation

With our pallets unibody construction and consistent dimensions, equipment runs better.

Track and Trace

Easily track shipments through RFID technology.

iGPS plastic pallets, combined with our innovative pooling system, provide the technology, service, and sustainability to meet the exacting requirements of the health and wellness industry. To get started with iGPS, reach out to our logistics experts today at 1-800-884-0225 or email us at info@igps.net. Our team will walk you through how our innovative shipping options can drastically lower your total cost of business.

The Seven Key iGPS Shipping Logistics Advantages for the Health and Wellness Industry

- Unprecedented safety and hygiene: Health and Wellness products must be shipped on plastic pallets that do not require chemical treatments of pesticides or fungicides. Wood pallets harbor bacteria, fungi, and pests. Plastic pallets are impervious to parasites and do not require the preventative measures of chemical treatment. They will not rot or absorb moisture.

- Reduced product damage: Health and Wellness products will be rejected by retailers if they have been punctured or damaged, as environmental exposure can lead to contamination. The iGPS plastic pallet is strong, uniform, and has no protruding edges or parts, reducing the chance that your packaged products will be damaged during transport.

- Industry-leading sustainability: Part of the Health and Wellness industry-wide commitment to consumers is delivering products that are good for their mind, body and the planet – which means relying on a greener supply chain. iGPS plastic pallets eliminate the need for wood platforms, reducing the industry’s consumption of trees, and are reusable and recyclable. They also require less fuel to transport, which reduces carbon emissions during transit. Use our greenhouse gas calculator to estimate the amount of carbon emissions you can reduce with iGPS.

- Lower transportation costs: At around 50 pounds, iGPS platforms are up to 35% lighter than standard wooden pallets. The result is lower costs when transporting your products from the warehouse to the retailer.

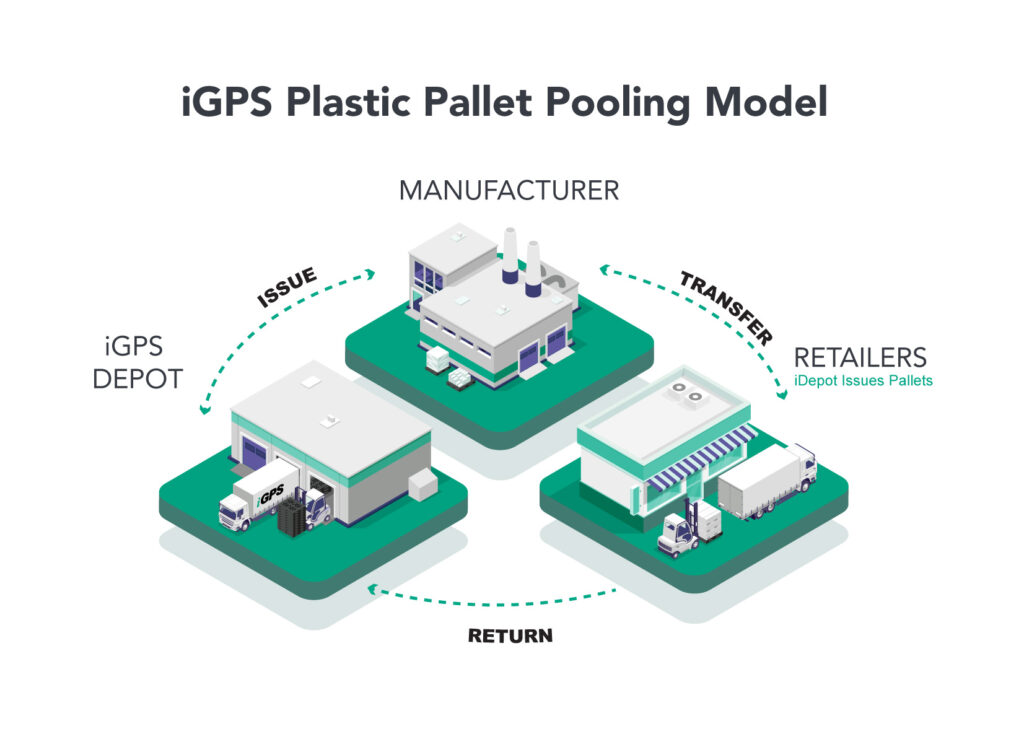

- Efficiency via a pooling system: Renting, versus buying, a fleet of sustainable, hygienic, durable pallets means your logistics energies are spent more efficiently than if you were to try to maintain and manage an in-house fleet of shipping pallets.

- Increased automation: Health and Wellness manufacturers need to prioritize shipping products on hygienic pallets compatible with the automated systems used by many vendors. The iGPS plastic pallet is ideal for automated systems as each is a standard 48 x 40 inches in dimension. Its uniform design will not cause errors in automated systems and eliminates unwanted product overhang. Shrinkage and warping are also not a concern with iGPS platforms, ensuring compatibility with automated guided vehicle (AGV) technology.

- Superior worker safety: The iGPS plastic pallet is safer for employees to work with than wood pallets, making handling pallets easier. Durable plastic eliminates gaps, broken boards, protruding nails, and splinters that can injure warehouse workers. The lightweight feature of the iGPS pallet also means a single worker can lift individual pallets.

Why Choose the iGPS Plastic Pallet Pooling System?

As a pallet pooling provider, iGPS offers the most cost-efficient and advanced plastic pallet-based supply chain solution for your business. We take care of pallet procurement, management, and recovery to ensure lower operating costs and optimum efficiency.

Pallets are procured, managed, and returned

Reduced risk of rejected loads

Reduced risk of product damage

No pallet storage and maintenance costs

Reduced transportation costs by minimizing dead legs and loads

iGPS is Setting a New Standard in Pallet Hygiene

iGPS’ platform was designed to reduce the risks associated with wood pallets.

- No nails or splinters: Studies commissioned by the FDA have found that “broken boards and popped nails” in wood pallets are a risk factor in product contamination.

- Impervious to liquids: Wood is absorptive by nature, and liquids penetrating wood raise the risk of cross-contamination and transmission of pathogens.

- No pesticides or fungicides: Wood is susceptible to insect infestation and plastic is not. iGPS platforms are never treated with pesticides or fungicides, including TBP and TBA.

- Meets the industry standards: Food Safety Modernization Act (FSMA) and all Grocery Manufacturers Association (GMA) specifications

Health and Wellness retailers are innovating the way we take care of ourselves and prioritize our well-being. Empower your supply chain—while lowering your TCOB—with the iGPS plastic pallet pooling system.