Plastic Pallet Pooling Benefits for

Produce

Every day, your customers are delighted by rows and rows of beautiful, fresh produce. They take joy in their grocery shopping experience and would never guess how much planning it took to put that produce on the shelves. But you know. And you know how hard it is to satisfy customers while navigating the supply chain’s many inherent challenges.

For produce retailers and manufacturers, it’s a long road to market. Consumers demand high-quality fruits and vegetables at low prices. That means costs must stay low along the supply chain so that savings can be passed on to shoppers. When your business is fresh produce, time is not on your side.

Eliminate Produce Shipping Challenges with iGPS

To meet consumer demands for low-cost, high-quality produce, as a manufacturer, supplier, or grocery retailer, you must find solutions that help lower your total cost of business (TCOB)—and the iGPS plastic pallet pooling system is your innovative answer to modern shipping logistics challenges.

iGPS plastic pallets combat major produce supply chain challenges with industry-leading pallet pooling technology. Letting iGPS work for you greatly reduces the risk of food contamination due to breakage during transit, lowers your transportation costs, minimizes product damage, increases hygiene, and cuts carbon emissions. Our plastic pallet pooling system helps to control costs by making the supply chain more efficient and eliminating the many risks posed by shipping fresh fruits and vegetables on outdated wood pallets.

Produce Spoils Quickly

The time to market for produce must be fast. If a shipment sits on a loading dock or in a warehouse because of a logistical inefficiency, i.e. “dwell time,” spoilage can easily occur. This risk has only increased as global supply chains have grown longer.

Hygiene is Crucial

Fruits and vegetables must be safe to eat and free of bacteria and other contaminants, as well as meet or exceed all U.S. Food and Drug Administration (FDA) and Food Safety Modernization Act (FSMA) standards.

Automated Systems Require Uniformity

Automated warehouse stock retrieval systems (ASRS) require pallets to be consistently uniform in size, weight, and dimensions. A misshapen or broken wood pallet can shut down a multi-million dollar automated system.

Wood Increases Contaminant Exposure

Wood pallets can potentially cause produce to become contaminated during transit; because they are porous and absorb liquids, they are often rife with bacteria such as E. coli and Listeria. They also attract insect and animal pests and can splinter or break during transit, both of which increase the risk of product damage and exposure to environmental contaminants.

Total Cost of Business is a Concern

Consumers demand ever lower prices. Total cost of business, or TCOB is positively impacted using the iGPS plastic pallet pooling system in a very significant way via increased efficiencies and cost savings. iGPS uses an intelligent pooling system that maximizes transportation savings, while lowering noxious carbon emissions into the atmosphere.

Sustainability is a Top Consideration

The supply chain must be sustainable. The level of carbon emissions per shipment has to be considered and lowered whenever possible. Additionally, used and broken wood pallets are increasingly clogging landfills.

To meet consumer demands for low-cost, high-quality produce, as a manufacturer, supplier, or grocery retailer, you must find solutions that help lower your total cost of business (TCOB)—and the iGPS plastic pallet pooling system is your innovative answer to modern shipping logistics challenges. To get started with iGPS, reach out to our logistics experts today at 1-800-884-0225 or email us at info@igps.net.

iGPS Produce Shipping Pallets Offer Seven Key Competitive Advantages to Suppliers

- Exceptional Food Safety and Hygiene: The iGPS pallet increases hygiene when shipping produce by reducing product damage during transit and thereby minimizing exposure to food contaminants. The iGPS plastic pallet is also made of a material impervious to insects and rodents, which does not rot or absorb moisture and effectively resists bacteria so that you will never need to subject an iGPS food-grade pallet to fumigation or pesticides. Our pallets meet or exceed the FSMA food safety and hygiene requirements.

- Lower Transportation Costs: Time and long distances are the enemies of the produce supply chain. The iGPS pallet delivers produce faster, for less. Weighing up to 35% less than the average wooden platform at around 50 pounds, our plastic pallet reduces total load weights, lowers fuel costs, and reduces CO2 emissions.

- Reduced Product Damage: The iGPS plastic pallet is reinforced to make it sturdy enough to hold even the heaviest produce loads. Each plastic pallet maintains its size and dimensions; unlike wood pallets, they will not splinter, have protruding nails, or develop sharp edges. This means your packaging will not get snagged, torn, or punctured during transit. Plastic iGPS pallets can also stand up to cold packs or dry ice without breaking. Never lose money on rejected deliveries again with shipments that arrive in pristine condition.

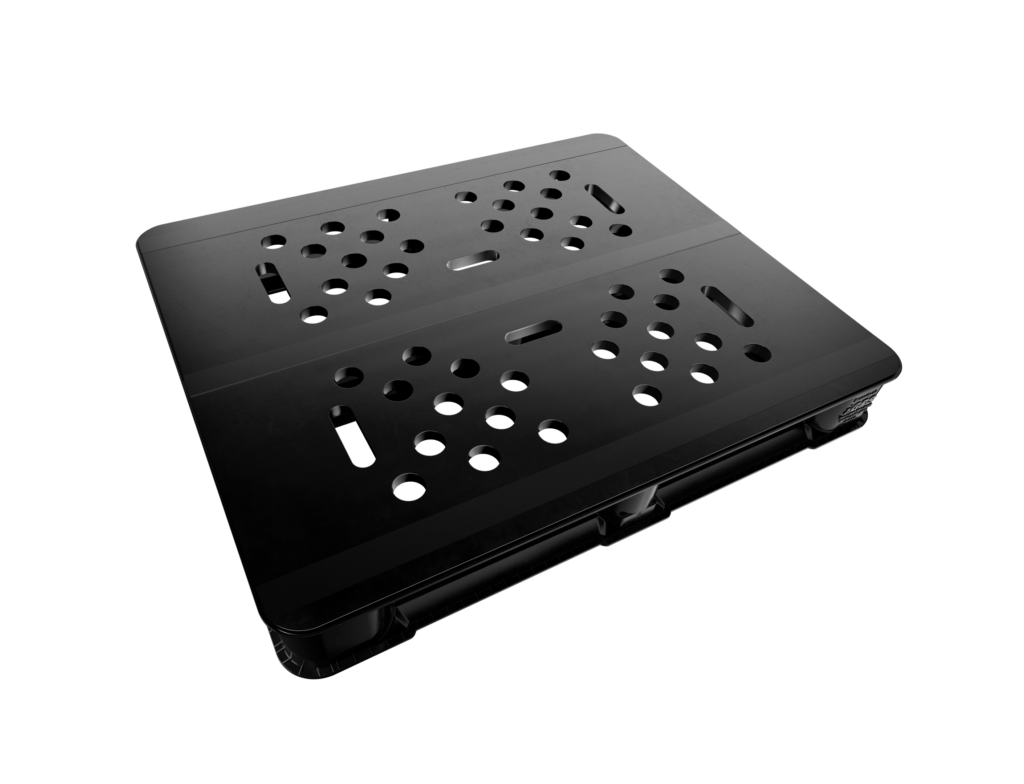

- Increased Automation: iGPS plastic pallets for processing and warehousing can be used as early in the supply chain as in the growing field and can stand up to refinement processes such as produce washing and drying. This utility eliminates the extra step of reloading pallets within a warehouse. iGPS pallets also scan smoothly through automated systems because each pallet is the same weight and a uniform 48 x 40 inches in dimension. This feature makes it an excellent value-add for retailers and manufacturers who have invested in automated systems and need compliant pallets that work seamlessly with automated guided vehicles (AGVs).

- Industry-Leading Sustainability: Produce manufacturers certainly have an interest in protecting the environment. That’s why you should avoid wood pallets with a finite lifespan that usually end their lives in a landfill. The iGPS pallet is a “cradle to cradle” solution: if a pallet is damaged, it can be recycled into a new one. Additionally, because plastic pallets are lighter than wooden ones, less fuel is required for transportation, which reduces carbon emissions. Our plastic platforms offer retailers and manufacturers an opportunity to join the push for a cleaner, greener, more sustainable supply chain.

- Superior Worker Safety: Worker safety is a critical issue, particularly in produce fields and warehouses. Our solution helps you raise your level of workplace safety by reducing the chance of injury caused by traditional wood pallets. iGPS plastic pallets have no gaps, broken boards, protruding nails, or splinters to cause workplace accidents. And, because they’re lighter, they’re safer and easier to move and can be lifted by one employee.

- An Efficient Pooling System: By renting pallets rather than buying them, you have at your disposal the exact number of quality pallets you need, when you need them. Pooling also eliminates the expense of purchasing, maintaining, and managing a pallet inventory; extra pallets take up valuable and costly storage space during periods of low demand. Pallet pooling enables you to focus on your core capital expenditures and day-to-day supply chain operations rather than waste company resources and time owning and maintaining an inventory of pallets.

iGPS Plastic Pallet Pooling: A Complete Logistics Solution for Produce Supply Chains

North Americans are becoming increasingly health conscious and eating greater quantities of fresh fruits and vegetables. While this is wonderful news for public health, it also means the produce supply chain must brace itself to meet ever-greater demand. The iGPS intelligent pallet pooling system can simultaneously increase your supply chain’s levels of efficiency, food safety, and sustainability by optimizing how warehouse and transportation assets are used.

Pooling means pallets are efficiently allocated and routed to maximize usage and transportation resources. When a manufacturer notifies iGPS of a shipment, we dispatch the correct number of plastic pallets by the truckload. The manufacturer then ships their products on our pallets to their distributors, who may store the products in warehouses or ship them to the retailer. Once the pallets have been unloaded at a retail outlet, the distributor returns the pallets to their distribution centers, which are sent to iGPS for inspection and reissue. The system is easy, cost-effective, and makes operations run more smoothly for supply chain operators.

iGPS Pallets:

Are sanitary enough for bagged lettuce but strong enough for bagged concrete.

Allow you to easily track shipments through RFID technology.

Meet the highest standards of platform hygiene, according to the FDA’s Food Safety Modernization Act.

Are compliant with Consumer Brand Association (CBA) specs.