Plastic Pallet Pooling Benefits for

Dairy & Eggs

Which two items consistently top grocery lists? Milk and eggs. Many a quick trip to the store has been made for one of these staples alone. Although ubiquitous in the American fridge, supplying consumers and their families with these products isn’t easy. Shipments must arrive at retail stores fast to avoid spoilage and increase store shelf life. Products must remain in a cold environment at all times. And, sanitation must be outstanding during production and manufacturing—as well as at every point along the transportation supply chain.

Dairy products and eggs are highly susceptible to spoilage or contamination from bacteria such as salmonella, Listeria, and E. coli. But consumer demand requires suppliers and retailers to offer them in ever-increasing numbers, at ever-decreasing prices. How can egg and dairy manufacturers deliver products that are fresh and meet FDA standards, while keeping their total cost of business (TCOB) low? The answer is the iGPS plastic pallet pooling system.

From Farm to Table, iGPS Delivers

Their highly perishable nature makes egg and dairy products exceptionally difficult to safely deliver to the consumer. And, when things go wrong it makes headlines. In 1994, 200,000 people nationwide were affected by ice cream contaminated with salmonella. The cause was determined to be wood pallets contaminated by raw eggs from a previous shipment—a completely avoidable, but not uncommon, situation in the dairy and egg industries.

Producers, manufacturers, suppliers, and retailers all play a crucial role in overcoming these logistics obstacles when bringing milk, eggs, and cheese to families’ tables:

Sanitation is Critical

Every surface a product comes in contact with must be kept sanitary during both production and transportation. This requires detailed attention to supply chain materials, such as ensuring that pallets are hygienic and that trucks are disinfected between loads. When products arrive on store shelves, they must meet or exceed all U.S. Food and Drug Administration (FDA) and Food Safety Modernization Act (FSMA) standards.

Sustainability is a Top Priority

Dairy cattle often come under criticism for producing methane emissions. The dairy supply chain, then, must take extra precautions to lower carbon emissions to deliver on its commitment to sustainability. Additionally, used and broken wood pallets are a major cause of solid waste that clogs landfills.

Egg and Dairy Products Must Be Kept Cold

These products require cooling facilities and specialized equipment to ensure they stay within a precise temperature range at all times to avoid spoilage.

CBA Compliance is a Must

Supply chains are required to use dairy and egg shipping pallets that meet Consumer Brands Association (CBA) specs.

Long Distances can Increase Spoilage

To prevent spoilage over long distances, where shipments may wait in warehouses or—even worse—on loading docks, the supply chain must be fast, flexible, and reliable.

Automated Systems Require Uniformity

Automated warehouse stock retrieval systems (ASRS) require pallets to be consistently uniform in size, weight, and dimensions. A misshapen or broken wood pallet can shut down a multi-million dollar automated system.

Wood Increases Contaminant Exposure

Wood pallets can contaminate eggs and dairy during transit because they are porous and absorb liquids, making them rife with bacteria such as E. coli and Listeria. They also attract insect and animal pests and can splinter or break, which increases the risk of product damage and exposure to environmental contaminants.

Total Cost of Business is Key

Consumers demand high-quality dairy and egg products at low prices. TCOB must therefore be lowered by raising supply chain logistics efficiencies via an intelligent pallet pooling system that does not waste transportation resources.

Any innovations in the supply chain that can help bring these delicate products safely and cost-efficiently to market are welcome. But is there a single, simple solution to overcome the entire range of dairy and egg industry logistics stumbling blocks? Yes—and that solution is the iGPS plastic pooling system.

To get started with iGPS, reach out to our logistics experts today at 1-800-884-0225 or email us at info@igps.net. Our team will walk you through how our innovative shipping options can drastically lower your total cost of business.

The Seven Key iGPS Shipping Logistics Advantages for the Egg and Dairy Industry

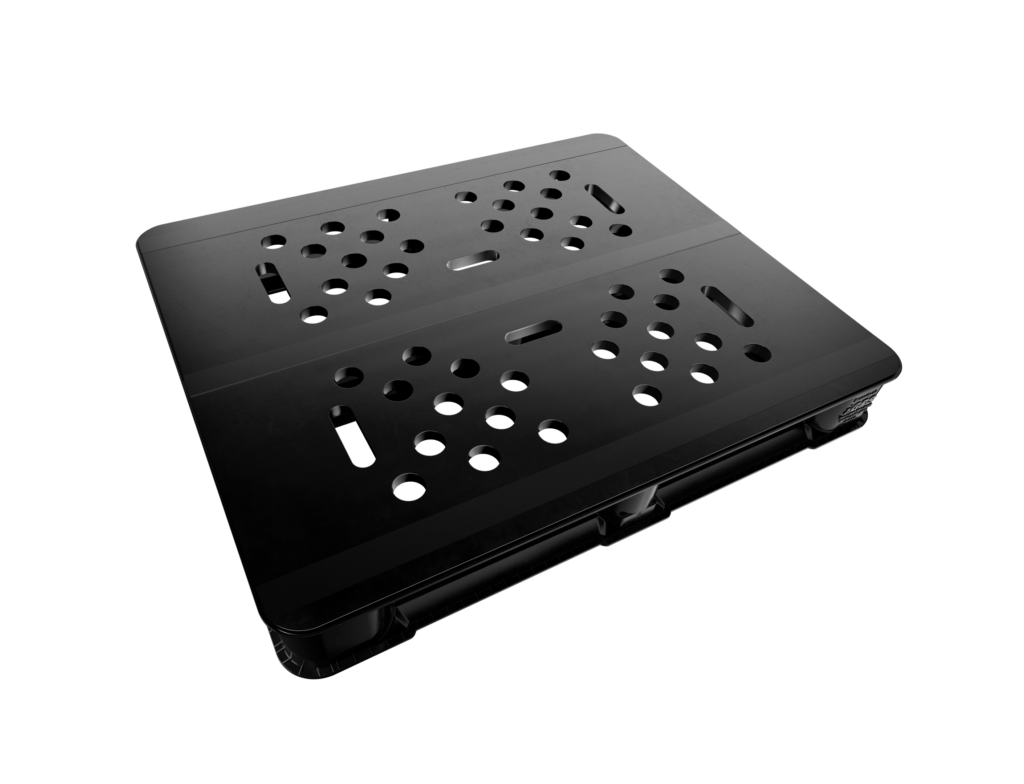

- Exceptional Food Safety and Hygiene: Given the stringent sanitation requirements of the egg and dairy supply chains, the iGPS plastic pallet is the only safe choice. It’s an easy pallet to clean and can withstand high water temperatures and pressure, as well as below-freezing temperatures, without cracking or shattering. Additionally, iGPS plastic pallets can be used early in the supply chain, during egg collection, and at the time of bottling milk, ensuring less opportunity for contamination in the factory as workers interact with products. Finally, the iGPS plastic pallet is made of a material that’s impervious to insects and rodents. It does not rot or absorb moisture and resists bacteria to meet or exceed all FDA and FSMA food safety and hygiene requirements.

- Lower Transportation Costs: Long-distance journeys are risk factors for egg and dairy products especially vulnerable to spoilage. The iGPS pallet delivers shipments faster, for less. At around 50 pounds, and weighing 35% less than the average wooden platform, iGPS pallets reduce total load weights and lower fuel costs.

- Less Product Damage: The iGPS plastic pallet is reinforced and sturdy enough to hold even the heaviest loads of milk products. Each plastic pallet is guaranteed to maintain its size and dimensions. Unlike wood pallets, they will not splinter, have protruding nails, or develop sharp edges that can snag or tear packaging during transit.

- Increased Automation: iGPS pallets scan smoothly through automated warehouse systems because each pallet is the same weight and uniform 48 x 40 inches in dimension. This feature makes them an excellent value-add for retailers and manufacturers who have invested in automated systems and need compliant pallets that work seamlessly with automated guided vehicles (AGVs).

- Incomparable Sustainability: Sectors of the food industry that rely on livestock are often scrutinized to ensure they reduce waste and are as environmentally friendly as possible. iGPS plastic shipping pallets are a “cradle to cradle” solution; if a pallet is damaged, it can be recycled into a new one—unlike wood pallets that litter landfills as solid waste. And, because plastic pallets are lighter than wooden platforms, less fuel is required for transportation, which reduces carbon emissions. To estimate the amount of carbon emissions the iGPS pallet can reduce for each of your shipments, try using our greenhouse gas calculator.

- Industry-Leading Worker Safety: When workers handle lighter, safer iGPS plastic pallets, worker safety naturally improves. This is especially a consideration when moving heavy loads of milk or ice cream. Our pallets reduce the chance of injury caused by traditional wood pallets as they have no gaps, broken boards, protruding nails, or splinters to cause preventable workplace accidents.

- An Efficient Pooling System: Pallet pooling enables you to focus on core capital expenditures and day-to-day supply chain operations rather than waste company resources and time owning, maintaining, and managing an inventory of pallets. By renting FSMA food-grade plastic pallets rather than buying them, you have at your disposal the exact number of quality pallets you need, when you need them.

If you are still using wood pallets to ship egg and milk products, your supply chain is suffering from inefficiencies that can be easily eliminated with the iGPS plastic pallet pooling system. Egg and dairy manufacturers and retailers need a plastic pooling system that lowers the TCOB and creates cost savings that can be passed on to consumers. In terms of logistics, inefficient wood pallets are simply outdated. It’s time to make the switch to sustainable plastics with iGPS.

Cream the Competition with iGPS Plastic Pallet Pooling

In a competitive market fraught with challenges, egg and dairy manufacturers and retailers can use a little friendly help with their logistics. The iGPS pooling system delivers quality pallets, on time, as required by the manufacturer. Once the pallets have been unloaded at a retail outlet, iGPS arranges for the return of the empty pallets back to one of their many depots throughout North America for inspection, cleaning, and, if required, repair. They are then reissued to another manufacturing customer.

The iGPS pallet pooling system is seamless, easy, and cost-effective, and helps your business become more flexible and competitive. With iGPS in your corner, it’s no contest: You, your retailers, and your customers win.

Only iGPS Plastic Pallets:

Are sanitary enough for bagged lettuce but strong enough for bagged concrete.

Allow you to easily track shipments through RFID technology.

Meet the highest standards of platform hygiene, according to the FDA’s Food Safety Modernization Act.

Are compliant with Consumer Brand Association (CBA) specs.

By leveraging iGPS to deliver unbeatable freshness and value, you create a customer experience that fosters lifelong loyalty and fuels the success of the dairy industry.