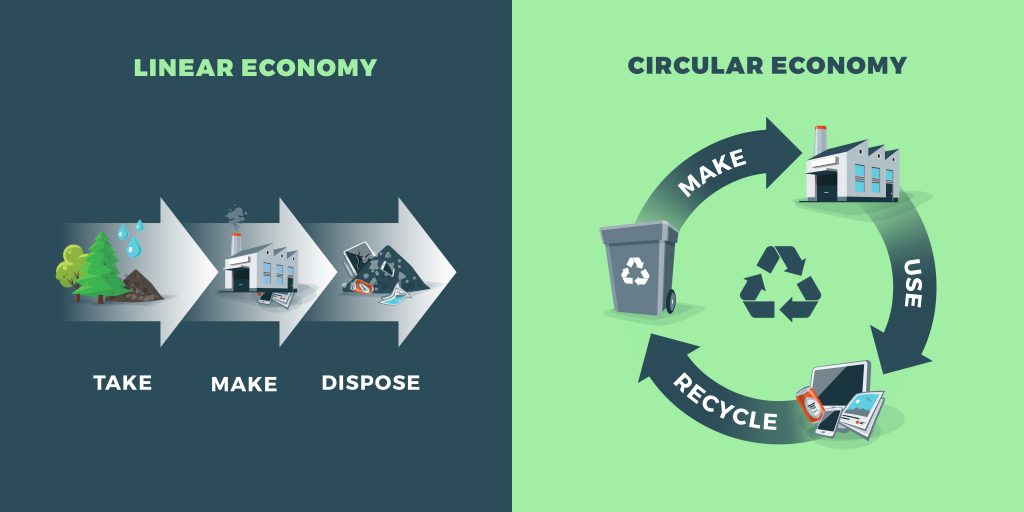

The traditional “take, make, dispose” linear business model, which has dominated economic activity for centuries, is reaching its breaking point. Escalating resource scarcity, growing environmental concerns, and shifting consumer expectations are forcing businesses to re-evaluate their strategies. The linear model, characterized by high waste and low resource efficiency, is no longer a viable long-term solution. In its place, a new paradigm is emerging: the circular business model.

A circular business model is a transformative strategy that minimizes waste and maximizes resource value by focusing on reusing, recycling, and regenerating materials. Unlike the linear model, which views products as disposable, a circular approach treats waste as a valuable input, creating closed-loop systems where materials are kept in use for as long as possible. By adopting circular principles, companies can not only reduce their environmental impact but also achieve greater operational stability, cut costs, and build a more resilient and sustainable future.

Key Takeaways

- Through reusing, recycling, and regenerating materials, a circular business model efficiently minimizes waste and maximizes resources.

- Linear models are growing increasingly unsustainable.

- Circular supply chains reduce harmful environmental impact, improve operational stability, and cut costs.

- Key principles of the model include designing for reuse, extending product life, and closing the material loop.

- Leading companies like IKEA and Patagonia are already adopting circular practices and have seen measurable success.

What Is a Circular Business Model?

A circular business model is a strategy that promotes reusing, recycling, refurbishing, and regeneration. Circular models focus on creating closed-loop systems where materials retain their value for as long as possible, unlike traditional models prioritizing mass production and disposal.

Traditional models use resource extraction, transportation, manufacturing, and waste disposal, which have significant environmental footprints. Therefore, the circular model is especially transformative through creating these eco-friendly supply chains. Waste becomes input in a circular model. The model is a sustainability initiative and competitive strategy for long-term resilience and efficiency. Products are designed for longevity, and end-of-life materials are returned through recycling or repurposing.

What Is a Linear Model?

The linear model operates on a very straightforward sequence. First, raw materials are extracted, made into products, sold to consumers, and discarded as waste.

Key characteristics of linear models:

- Significant amounts of industrial and post-consumer waste

- High consumption of materials

- Low rates of reuse or recycling

- Short product lifespans

- Limited accountability for post-sale impact

Linear models have supported decades of economic growth. However, as global demand for resources increases and climate challenges intensify, it is clear that the model is unsustainable in the long term.

Why Linear Models Are Failing

For several reasons, the linear economy is under pressure. First, waste disposal and environmental degradation from overconsumption are accelerating climate change and biodiversity loss. The Ellen MacArthur Foundation estimates that over 45% of global emissions come from how humans make and use products and food, much of which comes from linear systems.

Second, supply chain instability and resource scarcity are becoming business risks. Linear systems expose companies to volatility and increased costs as natural resources become more expensive or harder to access.

Third, public sentiment is starting to shift. Consumers are demanding accountability, transparency, and sustainable alternatives in supply chains and the missions of everyday brands they interact with. Governments are responding with regulations around carbon disclosure, extended producer responsibility, and waste reduction, forcing companies to shift from the linear approach.

Circular vs. Linear Business Model

The linear business model approach prioritizes volume and efficiency, but results in high resource consumption, short product lifespans, and harmful environmental impact. While effective in the past, this model is increasingly unsustainable.

Circular models offer products built for longevity and recyclability, enabling companies to reduce emissions, cut costs, and improve supply chain stability. Instead of relying on continuous extraction, circular models treat waste as a resource and prioritize long-term value creation.

Circular models encourage innovation, collaboration, and resilience by shifting from volume-based to value-based operations. As environmental and economic pressures grow, adopting circular strategies is becoming a forward-looking move for all businesses.

Key Principles of Circular Business Models

Creating a circular supply chain starts with adopting foundational principles that guide all aspects of design, sourcing, production, and end-of-life planning.

Core principles include:

- Design for repairability and durability: Products must be easily repaired or refurbished and made to last.

- Keep materials in use: Maximize products and materials being reused, shared, remanufactured, and recycled.

- Regenerate natural systems: Use regenerative processes and materials that enhance rather than harm the environment.

- Use waste as a resource: Create systems where waste from one product becomes input for another.

- Circular procurement: Source from suppliers that offer low-impact or recycled materials.

- Reverse Logistics: Develop infrastructure to collect used products and repurpose them in the value chain.

These principles close the loop and strengthen economic growth with environmental sustainability in mind.

Benefits of Circular Business Models

Beyond environmental stewardship, adopting a circular business model offers tangible benefits.

Key benefits:

- Cost efficiency: Reducing reliance on virgin materials lowers manufacturing costs and procurement.

- Resilience: By increasing operational stability, circular systems are less dependent on volatile global supply chains.

- Customer loyalty: Sustainable services and products build stronger brand affinity and trust.

- Regulatory readiness: Circular models prepare businesses for carbon reporting requirements and evolving environmental regulations.

- Reduced Waste and Emissions: Circular supply chains significantly lower landfill use, pollution, and greenhouse gas emissions.

Circular business models ultimately align economic and environmental value, supporting profitability and purpose.

Examples of Circular Business Models

Companies across numerous industries are adopting circular models and proving their effectiveness.

Notable examples:

- Patagonia: Patagonia encourages customers to repair, reuse, and return gear for resale, reducing waste through its Worn Wear program.

- IKEA: IKEA has pledged to become fully circular by 2030. Its initiatives include offering buy-back services for used products and designing furniture with modular components.

- Philips: Their “Lighting-as-a-Service” model installs, maintains, and upgrades lighting systems while minimizing waste and maximizing lifecycle value.

These examples demonstrate how circularity can be integrated into core business models as a driver of long-term value, not just a temporary fix.

Frequently Asked Questions

Is circularity only for large corporations?

Not at all. Small and medium businesses should implement circular strategies through local sourcing, rental models, or take-back programs. Digital platforms make knowing about circular practices more accessible than ever.

How do circular models impact profits?

While the first investments may be higher, circular models can reduce long-term costs, open new revenue options, and reduce regulatory risks. Many companies also gain customer loyalty and a competitive advantage through sustainability initiatives.

What role does technology play in circular supply chains?

Technology like AI supports tracking materials, predicts maintenance needs, and ensures transparency. These tools are critical for managing product lifecycles while improving system efficiency.

How is circularity different from recycling?

Recycling is one part of circularity, but not the entire picture. Circular models emphasize preventing waste from occurring through better design, repair, reuse, and business model innovation, whereas recycling is typically the last option.

Companies striving to optimize their supply chain operations and control costs depend on durable, lightweight iGPS plastic pallets for all their shipping needs. For more information, contact us at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page.