Cold chain logistics regulations, a vital component of the Food Safety Modernization Act (FSMA), aim to ensure the safe handling and transportation of temperature-sensitive products. Noncompliance with cold chain logistics regulations can result in significant repercussions, including hefty fines, costly penalties, rejected shipments, and wasted products.

Amidst the complex cold chain network, the safe transport of products from one point to another is critical. Each shipment stop introduces new environmental risks, increasing the likelihood of contamination and spoilage due to fluctuating temperatures. Minimizing pallet handling and movement between locations helps mitigate these issues. Plastic shipping pallets, with their easy-to-clean, sanitizable surfaces and RFID-tracking capabilities, further enhance safe product transport.

The Basics of FSMA’s Cold Chain Logistics Regulations

The landscape of cold chain logistics regulations underwent a noteworthy transformation with the enactment of the FSMA in 2011. This landmark legislation empowered the Food and Drug Administration (FDA) with expanded authority to oversee the handling and transportation of products throughout the entire supply chain, encompassing producers, retailers, and consumers. The Sanitary Transportation Rule, a key component of the FSMA, delves into the specifics of cold chain regulations, particularly those governing the transportation of food intended for human or animal consumption.

The Sanitary Transportation Rule encompasses three key areas: cleanliness and function of equipment, transportation protocols, and training.

- Cleanliness and function of equipment: This section requires periodic assessments of equipment, with a specific emphasis on refrigeration units, to confirm their effective operation and capability to uphold precise temperature control. Additionally, it establishes guidelines for cleaning trucks, pallets, and other equipment between loads, aiming to eliminate the risk of cross-contamination.

- Transportation protocols: The protocols section focuses on regulations for product handling during transport. This includes basic practices such as requiring employees to wear gloves and regularly checking the temperature of loads on individual pallets. It also covers timing, requiring that vehicles reach their destination within a reasonable timeframe to safeguard the integrity of temperature-sensitive products.

- Training: To uphold the integrity of the cold chain, employees are required to undergo training in the safe and proper handling of food. If employees acknowledge their role in safeguarding food integrity, can identify safety hazards, and articulate resolutions to potential issues, the training program is deemed sufficient in meeting this standard.

The FSMA and the Sanitary Transportation Rule have significantly bolstered the safety and integrity of the cold chain. These regulations, delineating guidelines for equipment upkeep, transportation procedures, and employee training, are pivotal in reducing the risk of food borne illnesses. They guarantee that temperature-sensitive products reach consumers safely.

How Plastic Pallets Support the Cold Chain’s Integrity

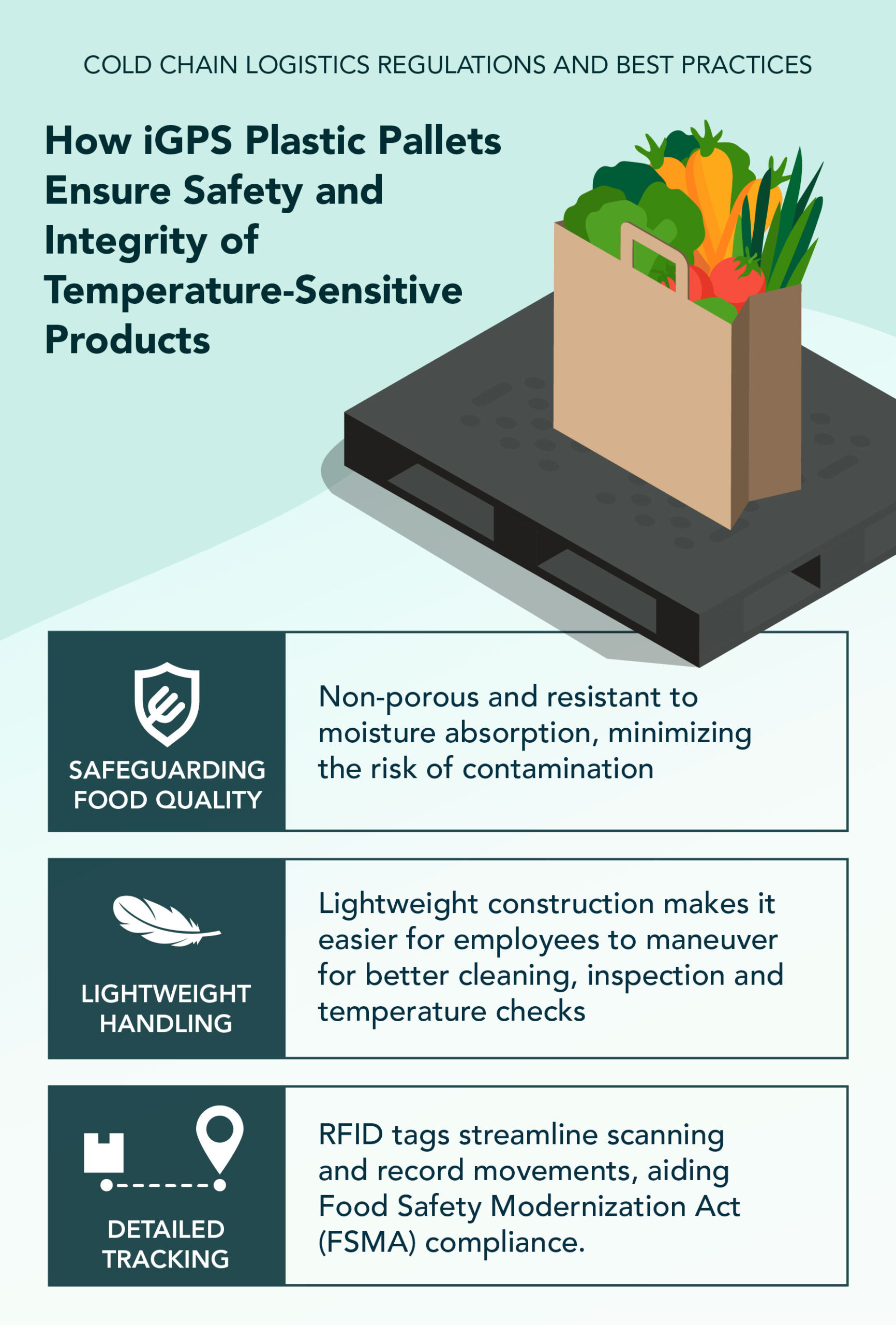

Plastic pallets can play a pivotal role in adhering to cold chain logistics regulations and best practices, ensuring the safety and integrity of temperature-sensitive products throughout the supply chain. These durable and versatile platforms offer several advantages that contribute to effective compliance, such as:

- Safeguarding Food Quality: Plastic pallets are inherently non-porous and resistant to moisture absorption, unlike their wooden counterparts. This characteristic minimizes the risk of harboring bacteria and pathogens, preventing cross-contamination, and safeguarding food safety. Plastic pallets demonstrate a significantly lower bacterial load compared to wooden pallets, reducing the likelihood of foodborne illnesses.

- Offering Lightweight Handling: Plastic pallets offer a significant advantage in terms of weight, typically weighing less than 50 pounds. This lightweight construction makes them considerably lighter than standard reusable wood block pallets, which can weigh upwards of 100 pounds. The reduced weight facilitates easier maneuverability for employees, enabling thorough cleaning, efficient inspections, and seamless temperature checks.

- Providing detailed tracking: Numerous plastic pallets feature RFID tags, allowing seamless scanning without requiring direct visibility. These tags enable a thorough record of pallet movements, including unloading times and facility exits, simplifying compliance with the Food Safety Modernization Act (FSMA) recordkeeping requirements. A 2023 report from the Grocery Manufacturers Association (GMA) emphasized the advantages of RFID-enabled plastic pallets in improving supply chain visibility and minimizing product losses.

Navigating the complex world of cold chain logistics regulations, particularly those governing product transport, can be a daunting task for supply chain managers. However, transitioning to plastic pallets can significantly simplify compliance efforts. Plastic pallets offer enhanced ease of use, superior cleanliness, and advanced tracking capabilities compared to their wooden counterparts. By embracing the advantages of sturdier, safer plastic pallets, supply chain managers can effectively address every cold chain regulation, regardless of its complexity, while also reaping cost-saving benefits.

iGPS plastic pallets help managers comply with cold chain logistics regulations by providing a sanitary, trackable platform for carrying products. For more information, contact us at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page.