If you’re building a pallet fleet, it’s crucial to know how long your pallets will last in order to make the best possible choice for your company’s needs. You may seek out short-term options that have a low upfront cost, like stringer pallets. Or, you might invest in more durable block pallets that offer longer-term use but also require a more substantial initial investment. No matter what type of pallet you’re looking for and what initial outlay you’re willing to make, it’s important to consider pallet longevity in terms of pallet turns or trips, rather than years, in order to get the most out of your pallet investment.

How Long Do Pallets Last? Estimating Longevity Based on Pallet Type

Anyone doing research on the question, “How long do pallets last?” will come across a lot of answers measured in months or years. This isn’t a good way to calculate longevity, as pallet use and maintenance greatly affect a pallet’s useful lifespan. A pallet that goes through 20 trips in a single year, for example, will break down much faster than one that makes only a few trips in that same time span. The best unit of measurement for determining the longevity of a pallet is pallet turns–i.e., how many times a pallet can make the trip from point A to point B before it breaks. Of course, repairs and refurbishment can usually extend the life of a pallet beyond this point. How long a pallet lasts, as well as whether it makes sense to repair it, depends on the pallet type.

Anyone doing research on the question, “How long do pallets last?” will come across a lot of answers measured in months or years. This isn’t a good way to calculate longevity, as pallet use and maintenance greatly affect a pallet’s useful lifespan. A pallet that goes through 20 trips in a single year, for example, will break down much faster than one that makes only a few trips in that same time span. The best unit of measurement for determining the longevity of a pallet is pallet turns–i.e., how many times a pallet can make the trip from point A to point B before it breaks. Of course, repairs and refurbishment can usually extend the life of a pallet beyond this point. How long a pallet lasts, as well as whether it makes sense to repair it, depends on the pallet type.

| Type | Description | Turns During Lifespan |

| Stringer Pallet | Stringer pallets are simple, inexpensive pallets often made of softwood. If repaired, they may be able to make two or three turns but are typically designed for single trips. | 1 to 3 pallet turns |

| Wood Block Pallet | Durable wood block pallets are heavier and more substantial than stringer pallets and are designed for multiple uses, though they will need regular repair. | 15 to 20 turns |

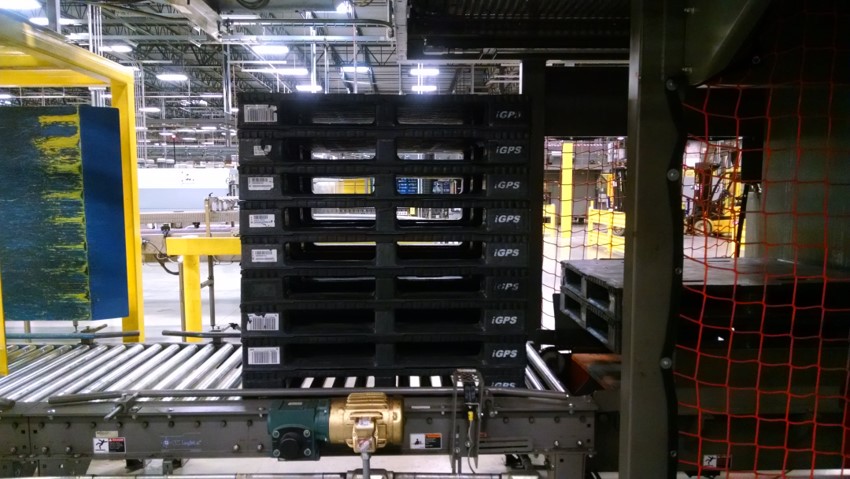

| Plastic Pallet | Plastic pallets are among the most durable on the market and are much less prone to breakage than either stringer or wood block pallets. | Up to 100 |

Renting your pallets through a pooling program is a cost-effective way to save on pallet maintenance and replacement.

Of course, pallet types other than those listed above are also available. Corrugated paper pallets are similar to stringer pallets in that they are typically only useful for a single trip, while steel pallets can make hundreds of trips but are expensive and very heavy. Wood and plastic are the most commonly used pallets due to their cost-effectiveness and their availability in bulk quantities. Whether you’re considering plastic or wood pallets, renting your pallets through a pooling program is a cost-effective way to save money on pallet maintenance and replacement.

How Pallet Pooling Extends Platform Longevity

Since pallet pooling involves the reuse of pallets, it makes the most sense in conjunction with tough, long-lived plastic pallets. Plastic pallet pooling offers companies enhanced sustainability, improved cost-effectiveness, and simplified logistics in the following ways:

Since pallet pooling involves the reuse of pallets, it makes the most sense in conjunction with tough, long-lived plastic pallets. Plastic pallet pooling offers companies enhanced sustainability, improved cost-effectiveness, and simplified logistics in the following ways:

- Sustainability: When plastic pallets reach the end of their long useful lives, they can be ground down and re-molded into entirely “new” pallets. This keeps them out of landfills while modeling a closed-loop supply chain system.

- Cost-effectiveness: The pooling model is much more cost-efficient for companies than managing an internal fleet, as it makes the pallet pooling company responsible for two of the most expensive parts of pallet ownership: platform upkeep and transportation.

- Simplified logistics: A pallet rental program manages the logistics of supplying and retrieving pallets, which eliminates the hassle of coordinating trips to pick up pallets from the end of the supply chain. It also means that managers can avoid the complexity and instability of the pallet market, particularly the market for stringer pallets, where a stable supply of quality pallets at a reasonable price is sometimes difficult and time-consuming to come by.

Plastic pallet pooling is a smart way to reduce your total cost of business.

So, how long do pallets last? It depends on the material type and the care they receive during use. Choosing pooled pallets relieves your company of the responsibility for repair, and picking durable plastic over more breakable wood means the pooled pallets delivered to your facility are less likely to have cracks, splinters, or other issues that could cost your company money in damaged products or employee injury. Plastic pallet pooling is a smart way to reduce your total cost of business (TCOB) while ensuring you never have to think about the longevity of your pallets again.

Renting iGPS plastic pallets offers major long-term cost savings for supply chain managers. Our pooling program shoulders the burden of pallet fleet management, so you can focus on improving your business. For more details, contact us at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page.