Plastic Pallet Pooling Benefits for

Pet Food

Pet owners tend to be a conscientious demographic. In addition to caring about their own pets’ wellbeing, they are often interested in social and environmental concerns as well. If a pet food brand, manufacturer, or retailer is linked to product recalls or sustainability issues, they take notice. They demand the highest standards of pet food quality and safety, particularly anytime the media becomes infused with stories of Listeria and salmonella outbreaks in pet products.

To garner brand loyalty from this group of choosy consumers, supply chain operators must take painstaking care to ensure products do not become contaminated during their trip to the retail market, and must demonstrate the reliability of their supply chain. Achieve this, and you’ll grow a consumer base that is happy to pay for your premium products.

How can you meet—and exceed—their expectations while keeping an eye on your Total Cost of Business (TCOB)? By leveraging an industry-leading logistics partner like the iGPS plastic pallet pooling system.

iGPS is Your Best Friend When it Comes to Pet Food Logistics Challenges

Hungry pets aren’t picky—their pet parents are. That’s why pet food supply chain operators have a hard time satisfying pet parents’ demands. If these problems sound familiar, you’re not alone. The pet food supply chain is hounded by demands, creating logistics challenges such as:

Salmonella Scares

The public is serious about keeping Salmonella out of the pet food supply chain. When outbreaks occur, it attracts a lot of media and legislative attention—just ask other large manufacturers that have lost consumer confidence in the past due to recalls. The Food Safety Modernization Act (FSMA) signed into law on January 4, 2011 has a zero-tolerance policy for Salmonella in pet food facilities.

Automation Requirements

Increasingly, pet owners purchase specialty feed through e-commerce companies. These vendors tend to have highly automated supply chains and modern warehousing systems which require modernized shipping pallets. These automated stock retrieval systems (ASRS) cannot operate with pallets that aren’t consistent in size and shape. A misshapen or broken wood pallet can shut down a multi-million dollar system.

Contaminant Exposure

Wood pallets can cause dry pet food to become contaminated during transit because they are porous, absorb liquids, and are susceptible to bacteria. They can also splinter or break during transit, increasing the risk of product damage and exposure to unhygienic environments. And, wood pallets attract pests that introduce unsanitary elements into pet food.

Total Cost of Business

Consumers demand ever lower prices. TCOB must remain low via increased efficiencies and the use of an intelligent pooling system that does not waste transportation resources.

Only the iGPS plastic pallet pooling system gives you the logistics tools needed to efficiently deliver pet food for less without compromising on quality. iGPS partners with you to help control supply chain costs, such as fuel and damaged products, while providing pallets that ensure automated systems run smoothly. To get started with iGPS, reach out to our logistics experts today at 1-800-884-0225 or email us at info@igps.net. Our team will walk you through how our innovative shipping options can lower your total cost of business.

The Competitive Advantages of Using the iGPS Plastic Pallet

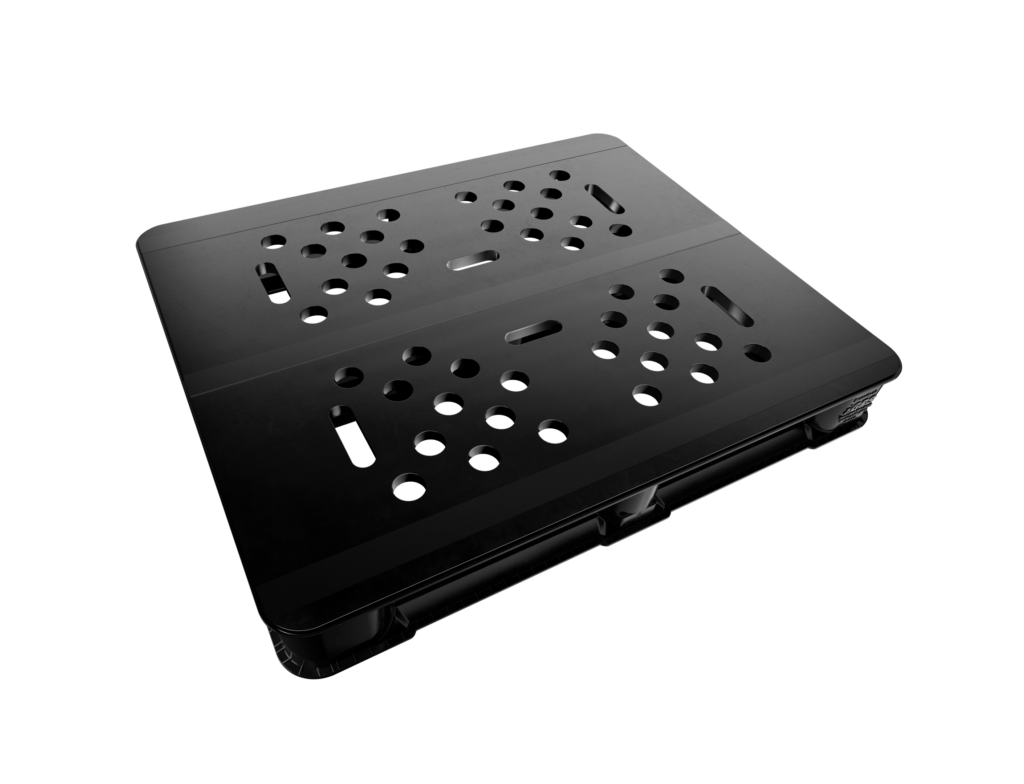

There are any number of logistics solution providers on the market, but the iGPS plastic pallet pooling system leads the pack. Our solution is made up of two key parts: modernized plastic pallets and the pooling service that enables you to rent the exact number of pallets you need, when you need them. It’s a solution that can help pet food supply chain operators overcome major challenges while delivering many benefits, such as:

- Unparalleled Food Safety and Hygiene: The pallets that pet food products are shipped on have an effect on their hygiene. Only the iGPS plastic pallet is impervious to insects and rodents, does not rot or absorb moisture, is highly resistant to bacteria, and eliminates foreign materials–such as wood chips–in the product. iGPS plastic pallets also meet the FDA’s FSMA standards, so pet parents can feel confident feeding their animal friends products delivered by your supply chain.

- Lower Transportation Costs: Bagged or canned pet food is heavy. Weighing around 50 pounds—up to 35% lighter than standard wood pallets—iGPS plastic pallets allow you to ship more product weight with reduced pallet weight. The result is lower fuel costs to transport your products from the warehouse to the retailer.

- Reduced Product Damage: The iGPS plastic pallet is sturdy, uniform, has no protruding edges or parts, and has no need for slip sheets, which can create huge cost savings. This integrated design reduces the chance that your product’s packaging will be damaged during transport. This is crucial to your bottom line because punctured bags of pet food cannot be sold as they are susceptible to contamination.

- Increased Automation: Modern warehousing systems commonly use ASRS technology. All pallets must adhere to consistent physical parameters or they can cause automated systems to have errors or even shut down. The iGPS plastic pallet is ideal for automation; each one is 48 x 40 inches in dimension. Its uniform design will not cause errors in automated warehouse stock retrieval systems and eliminates unwanted product overhangs. Shrinkage and warping are also not a concern with iGPS platforms, ensuring compatibility with automated guided vehicle (AGV) technology.

- Industry-Leading Sustainability: The public keeps an eye on how supply chains operate; all efforts to make your business more sustainable improve its public image. iGPS plastic pallets eliminate the need for wooden platforms, which reduces the consumption of trees. Our pallets are also reusable, long-lasting, and recyclable—a true cradle-to-cradle solution to the waste of wood pallets. They also require less fuel to transport, which reduces carbon emissions during transit. To estimate the amount of carbon emissions our plastic pallets for the pet food industry can reduce for each of your shipments, try our greenhouse gas calculator.

- Superior Worker Safety: When handling heavy loads of pet food, it’s important that plastic pallets do not slip, break, or cause accidents. The iGPS plastic pallet is safer for employees to work with than wood platforms and its built-in handholds reduce soft tissue injuries and make handling the pallets easier. Durable plastic also eliminates broken boards, protruding nails, and splinters that can injure warehouse workers.

- An Efficient Pooling System: Pallet pooling allows the pet food industry to deliver sanitary products with increased sustainability, as pooling enables a focus on capital expenditures and day-to-day supply chain operations. By renting our FSMA pallets rather than buying them, you eliminate the expense of purchasing, maintaining, and warehousing a pallet inventory.

Why Choose iGPS for the Pet Food Industry

The iGPS pallet pooling system gets the most value out of plastic pallets by managing them efficiently and intelligently. After a manufacturer ships their products and the pallets have been unloaded at a retail outlet, the iGPS team arranges for the empty pallets to be returned to one of our many depots throughout North America. There they are inspected, cleaned, and maintained before being reissued to another manufacturing customer. All of these pooling services enable your business to focus on the capital expenditures and day-to-day supply chain operations of your core business: keeping pets healthy and their owners happy.

iGPS Plastic Pallets:

Are sanitary enough for bagged lettuce but strong enough for bagged concrete.

Allow you to easily track shipments through RFID technology.

Meet the highest standards of platform hygiene, according to the FDA’s Food Safety Modernization Act.

Are compliant with Consumer Brand Association (CBA) specs.