Planning a delivery route is no easy task. And as the demand for goods goes up, planning the best route for delivery and meeting customer expectations only becomes more challenging. To safeguard against potential disruptions and streamline logistics, companies are putting an emphasis on optimized route planning.

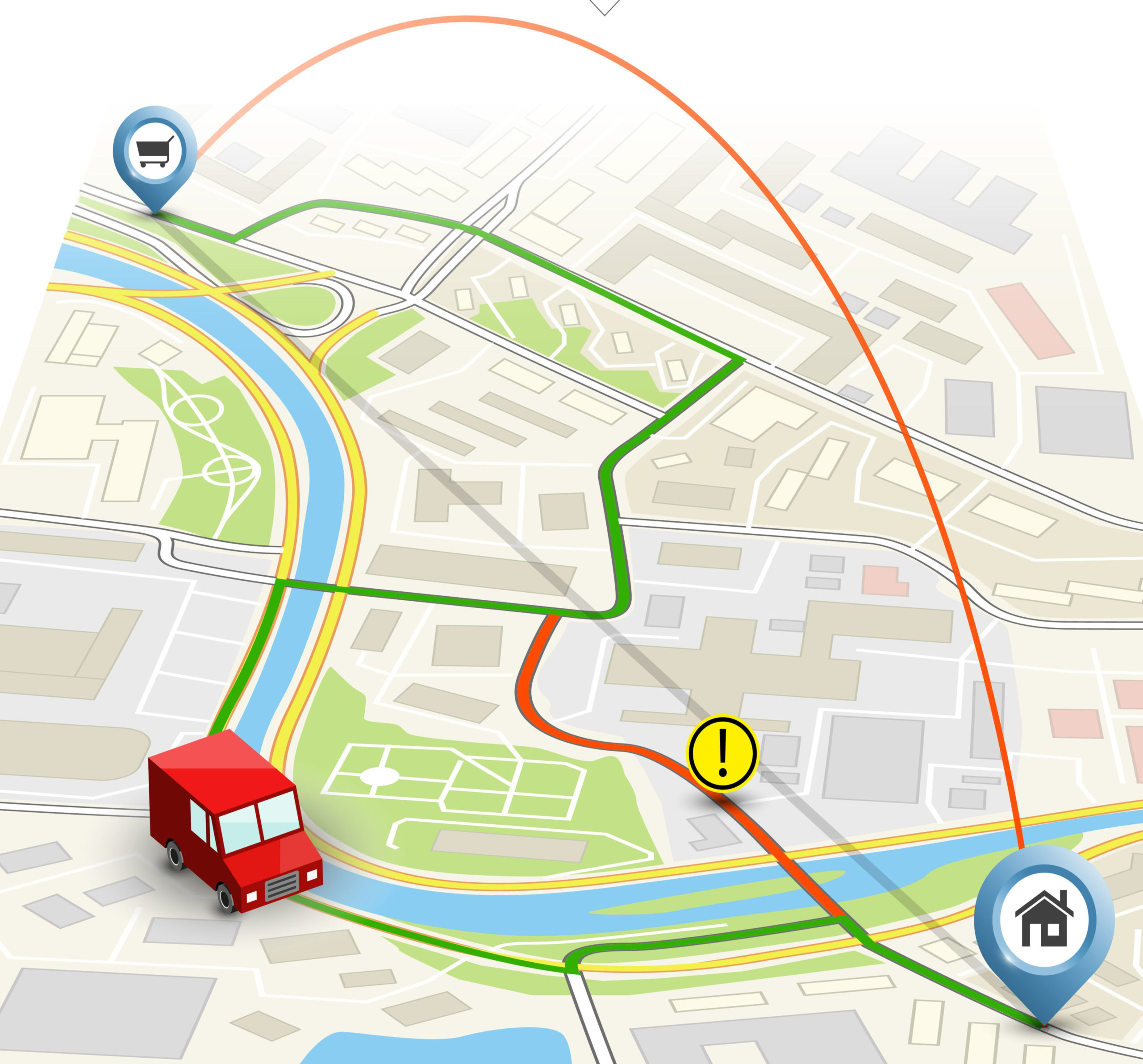

Optimized route planning involves finding the most efficient path for delivery personnel to take to get a shipment from point A to point B quickly and cost-effectively. However, this does not always mean the “fastest” route and there are many factors to take into consideration when planning the ideal route:

- Route congestion

- Driver schedule/availability

- Vehicle weight and capacity

- Road issues such as accidents

Today, there are numerous industry-specific technologies that can be used to assist in the optimized route planning process. Recently, Google announced two new tools for businesses to enhance their delivery processes — the Last Mile Fleet Solution, which puts an emphasis on optimizing every step of the last-mile delivery process, and the Cloud Fleet Routing API, which focuses on route planning across fleets of delivery vehicles.

Companies looking to optimize their route planning and overall delivery processes may also consider investing in other automation technologies and with industry strategic partners. A plastic pallet pooling company, for example, can help make logistics operations more efficient, thereby helping to streamline the delivery process. iGPS plastic pallets incorporate smart features that make them traceable throughout a supply chain. These features allow logistics companies to capture data at any point of distribution, ensuring better planning, efficiency, and helping to lower a company’s Total Cost of Business (TCOB). And because iGPS pallets are lighter, shippers can fit additional pallets of product onto trucks.

Benefits of Optimized Route Planning

Employee retention is an ongoing priority, and optimized route planning can translate into improved driver satisfaction. Having the optimal route planned out for them takes some of the stress and pressure off the driver while they are on the road. Drivers like to know that companies have invested time and resources toward helping them to succeed — and as businesses look to hire the future generation of drivers, optimization technology may even become a requirement for many looking to join the workforce.

Not only can optimized route planning lead to a more satisfied employee, but it can also improve their overall safety while out on the roads. Having the best route planned out mitigates any risk of turning down a narrow road or entering a zone where the truck will be over the weight limit, or too high for an overpass. These are critical factors to consider when planning a driver’s next route.

A driver’s main task should be picking up their deliveries and getting the products to their destination on time. Optimized route planning can assist them in this task by mapping out the most efficient way to move every product through the supply chain.

Companies committed to optimized route planning use iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable plastic pallets can help to streamline your supply chain and lower your Total Cost of Business. For more information, contact us at 1-866-557-0047, email a specialist at switch@igps.net, or visit our contact page.