ARTICLE UPDATED NOVEMBER 30, 2023

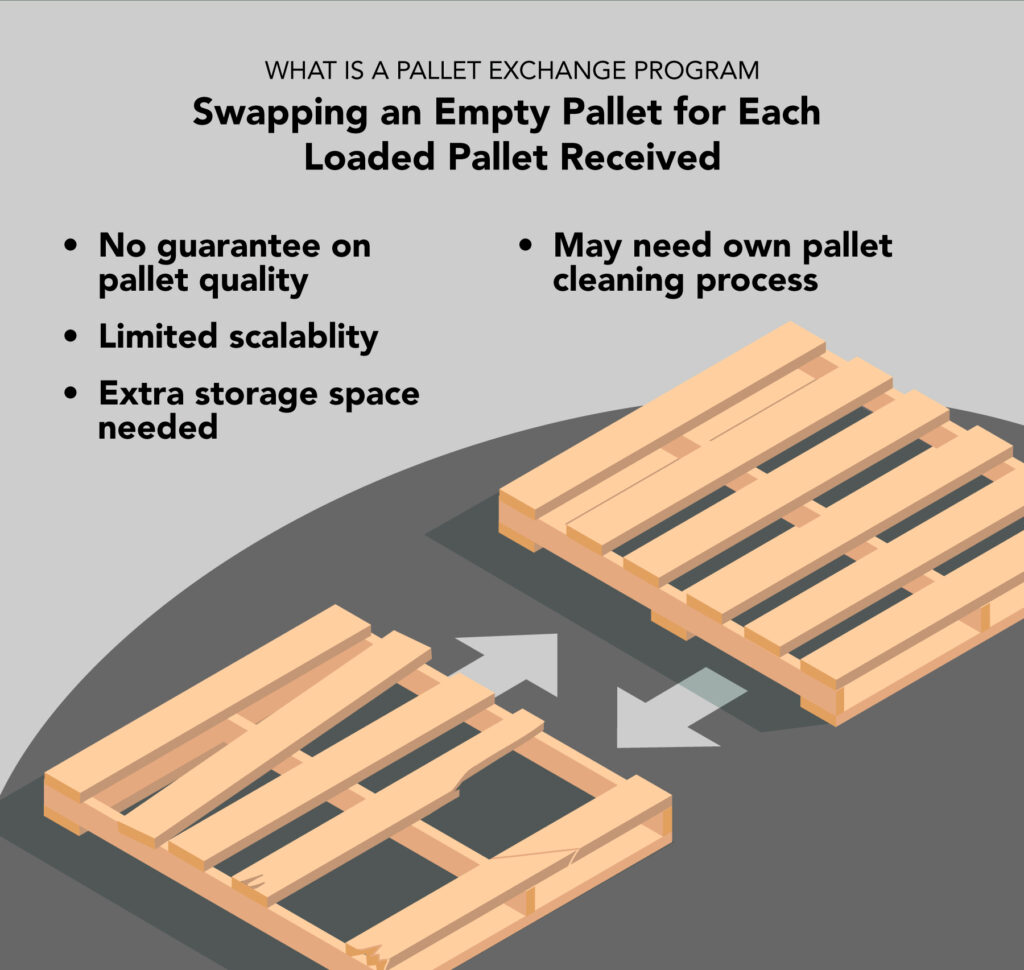

Managing a pallet fleet can pose significant logistical challenges for supply chain and facility managers. In addition to the need for adequate storage space for empty pallets, they must grapple with issues related to pallet cleaning, repairs, and retrieval. These tasks consume both time and financial resources that could otherwise be invested in revenue-generating activities, such as the timely delivery of marketable products. This predicament has led to the emergence of pallet exchange programs as a solution. Under a pallet exchange contract, recipients are required to swap an empty pallet for each loaded pallet they receive.

However, in today’s fast-paced, high-volume business environment characterized by rapidly shifting demands, pallet exchange programs have become an antiquated business model. Many managers seeking more diverse options and enhanced flexibility have explored alternatives to pallet exchange programs, including services like pallet pooling, i.e., pallet renting.

What Is a Pallet Exchange Program?

A pallet exchange program is a collective agreement between pallet shippers and receivers that aims to ensure that each party maintains the same number of pallets. When loaded pallets are brought to a warehouse or another receiver, they are exchanged for an equal number of empty pallets. Typically, a receiver will have exchange agreements with several suppliers to ensure there are enough pallets to go around. All pallets exchanged must be documented thoroughly to manage such a program.

Before pallet exchange programs, a shipper would often wait until all its pallets were emptied and returned or choose single-use platforms, which are both expensive and time-consuming. At this time, pallet exchanges acted as a viable alternative. However, these agreements are less popular than they once were, in large part because of their consistent drawbacks:

- Limited quality control:Empty pallets are often exchanged in stacks and, while pallet exchange contracts generally specify that pallets be in usable condition, there is no guarantee that every pallet received will be acceptable. Manufacturers must inspect each pallet to limit the risk of accepting broken or unsuitable platforms.

- Hygiene: Either party in the exchange may receive pallets that have been exposed to spills, pests, and other contaminants. As a result, they may need to complete their own cleaning process before use.

- Scalability: A pallet exchange program doesn’t offer the flexibility to increase or decrease a company’s pallet supply on short notice. The receiver must provide the same number of empty pallets to the shipper as the number of loaded pallets they receive. This can create challenges during periods of high demand in which extra pallets are required. It can also be problematic for facilities with limited space, as they are responsible for storing excess pallets during periods of low demand.

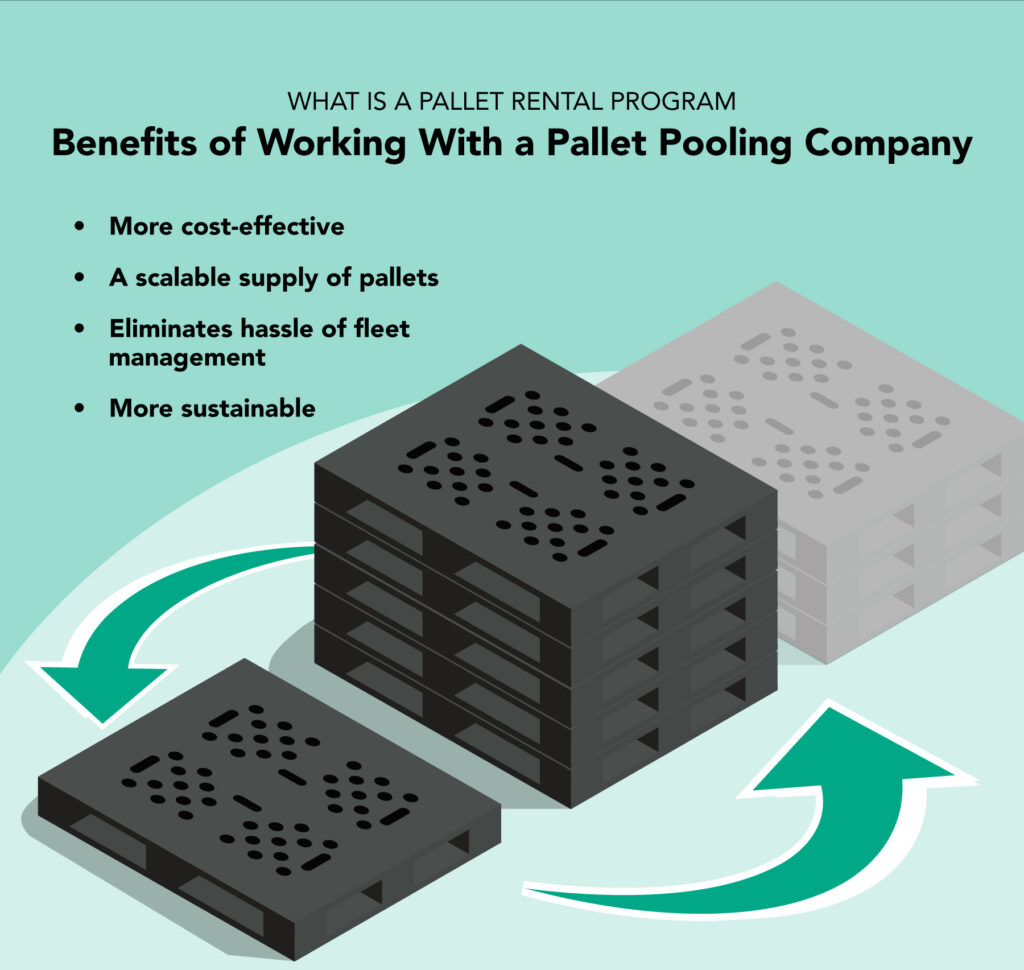

The downfalls of the pallet exchange process are among the reasons for the popularity of pallet rental programs, also known as pallet pooling. The pallet pooling model minimizes the hassle of pallet management on the receiver’s side and ensures an appropriate and flexible supply of pallets.

Why Choose a Pallet Rental Program?

The pallet pooling model relies on a pallet rental company that specializes in pallet supply and management. While programs vary, most follow several standard steps.

- Order: The supply chain manager submits a request to the pallet pooler for the number of pallets they need.

- Use: Pallets are received at the warehouse, distribution center, or manufacturer and loaded with product.

- Pickup: After the pallets reach the end of the supply chain, the pooling company arranges for retrieval.

- Clean and sort:If necessary, the pooling company inspects, cleans, and repairs pallets. In a closed-loop model, such as through the iGPS iDepot program, a retailer may perform this step.

- Return to pool: Pallets are returned to the pool for their next use.

This model eliminates much of the hassle of the pallet exchange program by putting the onus of pallet care on the pallet management company. Pallet pooling releases supply chain managers from the responsibility of transporting pallets for cleaning or repair. It’s also a more sustainable option because it streamlines pallet transportation by taking advantage of the pooling provider’s network of customers and retailers to move pallets as needed efficiently. This can remove extra transportation legs from the supply chain.

The other clear advantage of the pallet pooling model is scalability. A pallet rental program allows the shipper to request more or fewer pallets according to demand at any given time. This eliminates the need to hold onto an overflow pool of pallets for peak demand periods, freeing up storage space in the facility. Additionally, a pallet pooling provider that specializes in lightweight, durable, and recyclable plastic pallets instead of traditional wood ones takes pooling one step further, making it more hygienic, sustainable, and cost-effective.

The other clear advantage of the pallet pooling model is scalability

Most supply chain managers will find that the standard pallet exchange program has more than a few flaws that can be detrimental to business operations. A pallet pooling program, on the other hand, offers a scalable supply of pallets and eliminates much of the hassle of fleet management and pallet exchange while saving time and money.

Companies interested in pallet pooling should consider iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable plastic pallets incorporate RFID technology, making them traceable throughout a supply chain. For more information, contact us at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page.