Supply Chain Intelligence with Built-in RFID

For over a decade, iGPS has been a proven leader in embracing RFID (Radio-frequency Identification) tracking throughout the supply chain. Since day one, iGPS has equipped every pallet produced in our pool with RFID tags. Having the largest deployed RFID pool in the world allows our customers to utilize data-driven intelligence from our pallets in ways that traditional pallet users cannot.

We enable our customers to use RFID in almost every facet of the supply chain, from conveyors to dock doors. We work in consultation with our customers to read our pallets, to offer equipment recommendations, and to share lessons learned based on applications to help customers integrate as painlessly as possible.

iGPS RFID Benefits

Automation

iGPS’ RFID-enabled pallet allows automation to be more seamless across a wide array of applications. The intelligence of a unique serialized pallet bridges the gap between automated systems to understand what that pallet is, and where it needs to go.

- Automated Guided Vehicles (AGV) Forklifts

- Automated Putaway and Storage Systems

Tracking & Traceability

Associate a License Plate Number (LPN) to our iGPS RFID-enabled pallets to track and trace your product within your facility and to its destination by wirelessly reading at critical choke points.

- Identify and trace product movements throughout a facility

- Track product movements upstream and downstream through the supply chain

- Insight to locate pallets

Accuracy & Loss Reduction

Track loads and product by wirelessly reading iGPS RFID-enabled pallets on inbound, outbound, and key points within your facility.

- Ensure shipping and receiving pallet counts match shipment details

- Accurately report product movements within a facility

- Increase inventory and usage accuracy

Efficiency

Use data-driven metrics at and between read points to understand how efficiently a particular process within your facility is operating.

- Understand cycle times, process times, forklift driver efficiency, and more

Technical Specifications

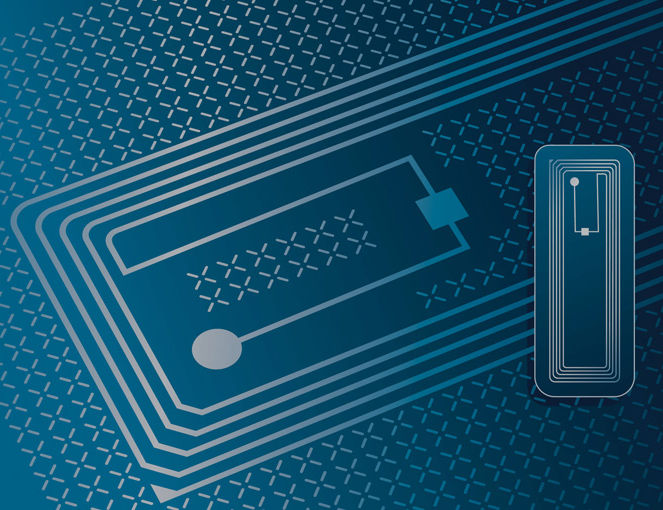

GS1 STANDARD – All pallets are equipped with passive UHF RFID tags, meeting the GS1 EPC Class 1 Gen 2 standard. This standard allows equipment to be purchased, from various vendors, that is guaranteed to work with our pallets.

QUADRUPLE REDUNDANCY – Each iGPS pallet has four identical RFID tags internally embedded during the manufacturing process. All tags are “three-way readable” via RFID, with four accommodating Code 128 1D barcodes. Optimum tag placement ensures durability and readability.

UNIQUE SERIALIZED PALLETS – iGPS is the world’s first asset pooling company to use the EPC GRAI tag ID standard on 100% of its assets. Each pallet has a unique serial number that is tracked through the supply chain.

iSUM3 SYSTEM – We provide the most scalable real-time RFID information system in the world, designed from the ground up to provide unprecedented asset visibility and reporting. iSUM2 is built on the latest technology from Microsoft, including SQL and Windows Server.