When we think of the supply chain, we typically focus on the journey of materials to manufacturers and products to retailers and consumers. Equally important, however, are the logistical processes that go into moving a product from the consumer back to the retailer or manufacturer. Having an efficient reverse logistics plan is crucial to the success of any supply chain. In recent years, consumers have grown to expect seamless return policies and product recycling programs (for example, for empty printer cartridges) that are easy and efficient. By examining and perfecting their reverse logistics processes, organizations can achieve improved customer satisfaction, and in some cases streamline costs along the way.

What is Reverse Logistics?

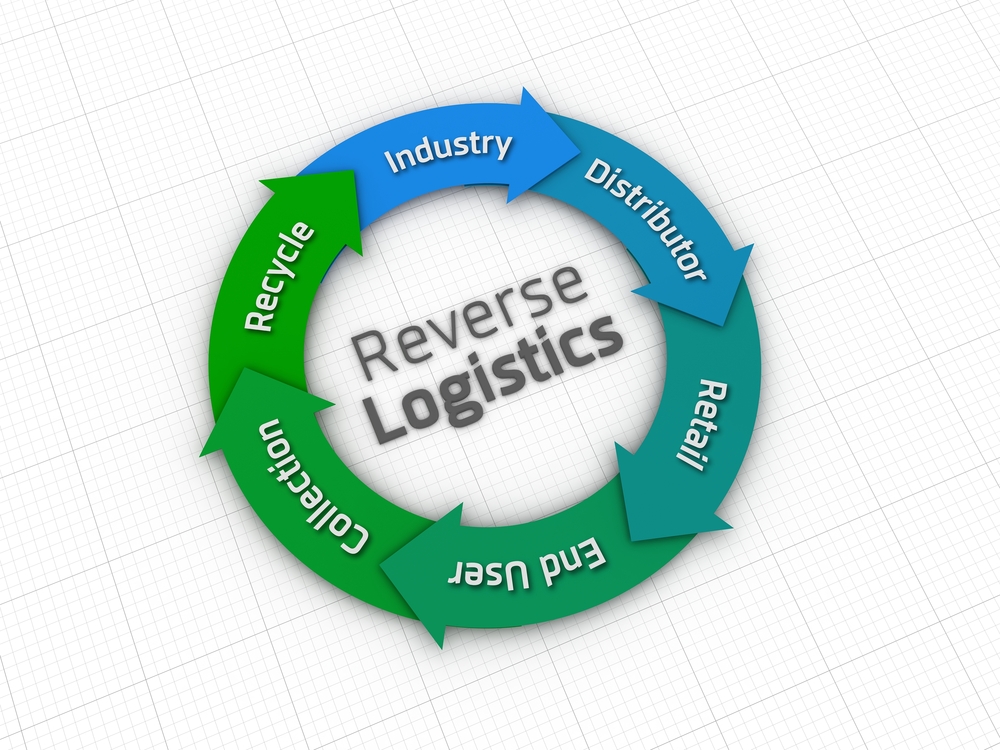

Reverse logistics involves supply chain management processes that move goods from the consumer back to a retailer or manufacturer. This can involve product returns, recycling programs, or sales or trade-ins of products to be refurbished.

Like most other systems within the global supply chain, reverse logistics processes have experienced disruptions over the last few years due to the pandemic. As e-commerce activity began to rise, for example, so did increased volumes of online returns.

According to one survey, a record $761 billion worth of merchandise was returned in 2021, and these returns generate 16 million metric tons of carbon emissions during their reverse logistics journey. E-commerce leaders are continually exploring ways in which to make the process less cumbersome for consumers, less impactful for the environment, and less expensive for themselves. Amazon now allows returns at more than 18,000 brick-and-mortar locations, including Kohls and some Whole Foods stores, and they also launched a donation program in 2019 that enables some excess and returned goods to be distributed to a network of 100,000 charities.

The pandemic and resulting supply chain snarls not only impacted the volume of returns coming in, but this also created a need for added layers in the reverse logistics cycle. During the onset and peak of the pandemic, instead of simply processing a return or recycled product in the usual fashion, retail and fulfillment center workers had to sanitize and quarantine returned products — adding more time to the process and delaying that product moving back into the supply chain. Retailers, in particular, found themselves needing to adapt quickly. Best Buy, the multinational consumer electronics retailer, saw the need for reverse logistics rising and quickly opened a new dedicated location to process online returns and increased their staff to handle the growing demand.

The movement of packaging and shipping assets also involves reverse logistics processes. Here at iGPS, our iDepot network fuels a circular economy in which our pallets are continually reused via a process that both saves time and minimizes strain on the environment. In a typical pallet pooling process, a pallet is shipped from a depot to a manufacturer, loaded and shipped to a retailer, and then returned to a central depot for inspection and repair — a three-step process.

The iDepot model eliminates a step and reduces deadhead miles via a partnership with retailers who sort and inspect iGPS pallets and send them directly to another iGPS customer. This method significantly streamlines the reverse logistics process and promotes a more sustainable circular supply chain.

The iDepot model eliminates a step and reduces deadhead miles via a partnership with retailers who sort and inspect iGPS pallets and send them directly to another iGPS customer. This method significantly streamlines the reverse logistics process and promotes a more sustainable circular supply chain.

Strengthening reverse logistics can also contribute to a retailer’s sustainability efforts. Receiving products back in an organized and efficient manner allows retailers to refurbish, resell, or recycle the goods to be used in a different way — elongating the lifecycle of the products and increasing their sustainability.

In a time when online shopping volumes continue to skyrocket, and customers expect increasingly simple and inexpensive return options, reverse logistics is a key component in the success of any business’s supply chain. When managed correctly, these processes can increase customer satisfaction, keep costs under control, and allow organizations to remain competitive in a continually evolving business environment.

Companies committed to enhancing their reverse logistics practices use iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable plastic pallets can help reduce harmful emissions and lower your Total Cost of Business. For more information, contact us at 1-866-557-0047, email a specialist at switch@igps.net, or visit our contact page.