ARTICLE UPDATED ON NOVEMBER 28, 2022

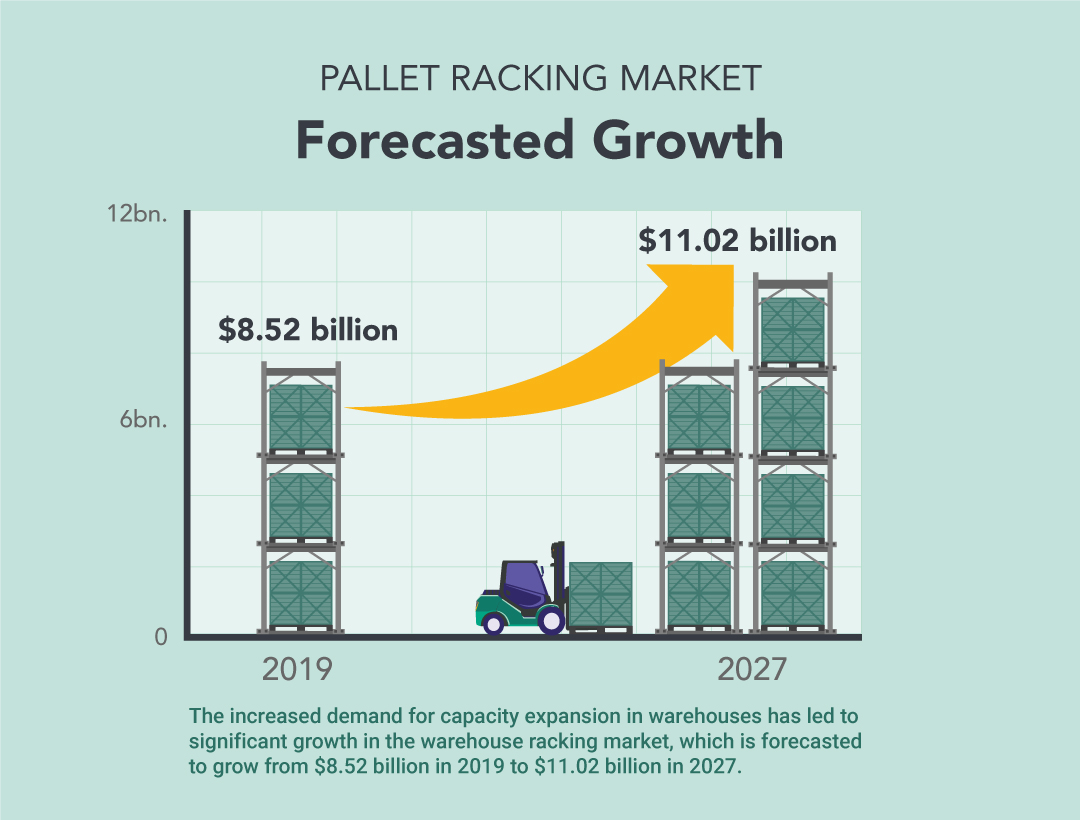

The demand for home delivery and the rise of e-commerce operations has led to significant growth within the warehouse industry, with a 2021 study citing that demand for warehouse space in 2021 had grown by 22% year-over-year, greatly exceeding the need in 2019 and 2020. To compete with the growing demand for speedy delivery of goods, companies across the board are streamlining warehouse operations with tactics such as optimized pallet racking. Businesses must prioritize warehouse optimization, which means putting an emphasis on the use of space in storage facilities and fulfillment centers. This creates an intentional workflow that allows for maximum efficiency and safety. The increased demand for capacity expansion in warehouses has led to significant growth in the warehouse racking market, which is forecasted to grow from $8.52 billion in 2019 to $11.02 billion in 2027. Improving warehouse space management helps enterprises lower their total cost of ownership (TCO) and total cost of business (TCOB) across the entire supply chain.

Pallets are one of the most important mechanisms in the supply chain and significantly influence the outcome of a shipment — for example, whether a product arrives undamaged. From the way that they are packed, to the system of storage used, pallet racking can considerably increase the cost efficiency of an operation. Before choosing a pallet racking system, businesses need to assess their available space and surface area as it relates to their inventory.

Why Your Warehouse Needs a Pallet Racking System

Pallets are one of the major components in a supply chain and can significantly impact the outcome of a shipment. The way both loaded and empty pallets are stored in warehouses can influence the efficiency of overall supply chain operations, and the ease of installing and using different types of pallet storage methods can greatly improve the profitability and productivity of these warehouse operations. The following are the benefits of pallet racking that can increase the cost-efficiency of your warehouse:

Optimizing Warehouse Space

Pallet racking allows businesses to build vertically, which saves precious warehouse space and allows for ease of inventory and workflow management. Push-back racking systems increase storage capacity for high-density product stock-keeping units (SKUs). Drive-in or drive-through pallet racks save space by decreasing the number of aisles within a warehouse or fulfillment center so that workflow can be managed more easily.

Improving Warehouse Safety

As demand for convenience and rapid fulfillment has increased over the last several years, so too have injury rates for warehouse workers. According to a 2020 study by the U.S. Bureau of Labor Statistics, for every 100 full-time employees, there were 4.8 recordable injuries among warehousing and storage workers. A busy warehouse can greatly benefit from a pallet racking strategy as it streamlines workflow, minimizes clutter, and eliminates common hazards that can lead to workplace injury.

Increasing Bulk Storage Capacity

In warehouses with deep inventory needs, a pallet racking system increases bulk storage capacity. The push back pallet racking system offers a static rack structure with carts to move along the rails that increase storage capacity for the high density of product stock-keeping units (SKUs). With the help of drive-in or drive-through pallet racks, bulk storage in each row reduces the total number of aisles required to reach the products.

Implementing Different Inventory Control Methods

Different products require different inventory management tactics. Whether it is first-in, first-out (FIFO) or first-expired, first-out (FEFO), care must be taken to develop a blueprint for the most efficient and supportive infrastructure within a warehouse or fulfillment center. Digital tracking and automation becomes easier with pallet racks installed in high-density automated warehouse storage and must be considered when designing a pallet racking system

Customizing Warehouses

Pallet racks allow for quick and easy access to inventory. When they are organized efficiently, warehouse clutter is reduced which makes navigating and completing tasks easier. Depending on the type of inventory, the shape of the space, and the timeline in place, pallet racking can be customized to integrate well with a warehouse’s infrastructure.

Benefits of Pallet Racking with Sturdy, Rackable and Sustainable Plastic Pallets

Plastic pallets maximize the benefits of pallet racking, taking racking systems to the next level with high-quality, lightweight, smart design. Using recycled plastic pallets over traditional wooden pallets for racking yields numerous benefits:

- Unibody construction: Plastic pallets lower risks of failure with heavy loads, which means that goods are less likely to get damaged by splinters or loose nails, and employees are safer as pallets are moved throughout the warehouse.

- Nonporous surface: Since plastic pallets do not absorb moisture, they eliminate contaminants and potential bacteria growth, which makes for a cleaner warehouse environment.

- Automation: With embedded RFID systems in plastic pallets, companies can digitally track and trace products in high-density storage situations, allowing for ease of movement and optimal organization.

In addition to keeping loaded pallets in racking systems, managing empty pallets is of equal priority. Empty pallets need to be stacked inside the warehouse safely, to avoid damage and potential safety hazards. Rather than purchasing pallets, companies can pool pallets. This avoids acquiring and maintaining an extra fleet of pallets and reduces the need for additional warehouse space. With a third-party maintaining the supply and retrieval of pallets from their end destinations, the overall cost-efficiency of warehouse operations increases.

The durable nature of plastic pallets also allows them to move throughout the supply chain without getting easily damaged. This is ideal for pooling, as renting pallets from a common pool allows managers to store only the most essential pallets at a given time, further enhancing the warehouse floor space.

Companies committed to optimizing their inventory management use plastic pallets from iGPS, which are lightweight, recyclable, and help streamline your supply chain. For more information, contact us at 1-866-557-0047, email switch@igps.net, or visit our contact page. We also invite you to follow us on LinkedIn.