ARTICLE UPDATED FEBRUARY 29, 2024

If you are involved in the field of logistics, you may be facing challenges in recruiting and maintaining a full workforce, which may be leading to difficulties in meeting productivity targets and ensuring compliance with your shipped goods. Recent trends in the supply chain, such as workforce shortages and increased demand seem to persist without any signs of diminishing.

In response to these challenges and the need for enhanced process control, logistics managers are increasingly turning to warehouse automation. However, a significant drawback of fully automating a warehouse is the substantial investment required, involving the installation of conveyor belts, aisle cranes, and tracking systems. Moreover, this installation process can render a facility non-operational until completion.

Nonetheless, there is an appealing alternative to certain types of human-controlled facility transportation in the form of autonomous guided vehicles (AGVs), which are becoming increasingly reliable and cost-effective. AGVs can be employed either independently or in conjunction with an Automated Storage and Retrieval System (ASRS), and they are highly adaptable to different aspects of your supply chains, whether it’s at the container or load unit level. This adaptability makes AGVs a versatile solution for addressing key challenges in logistics and supply chain management.

Types of AGVs in the Warehouse

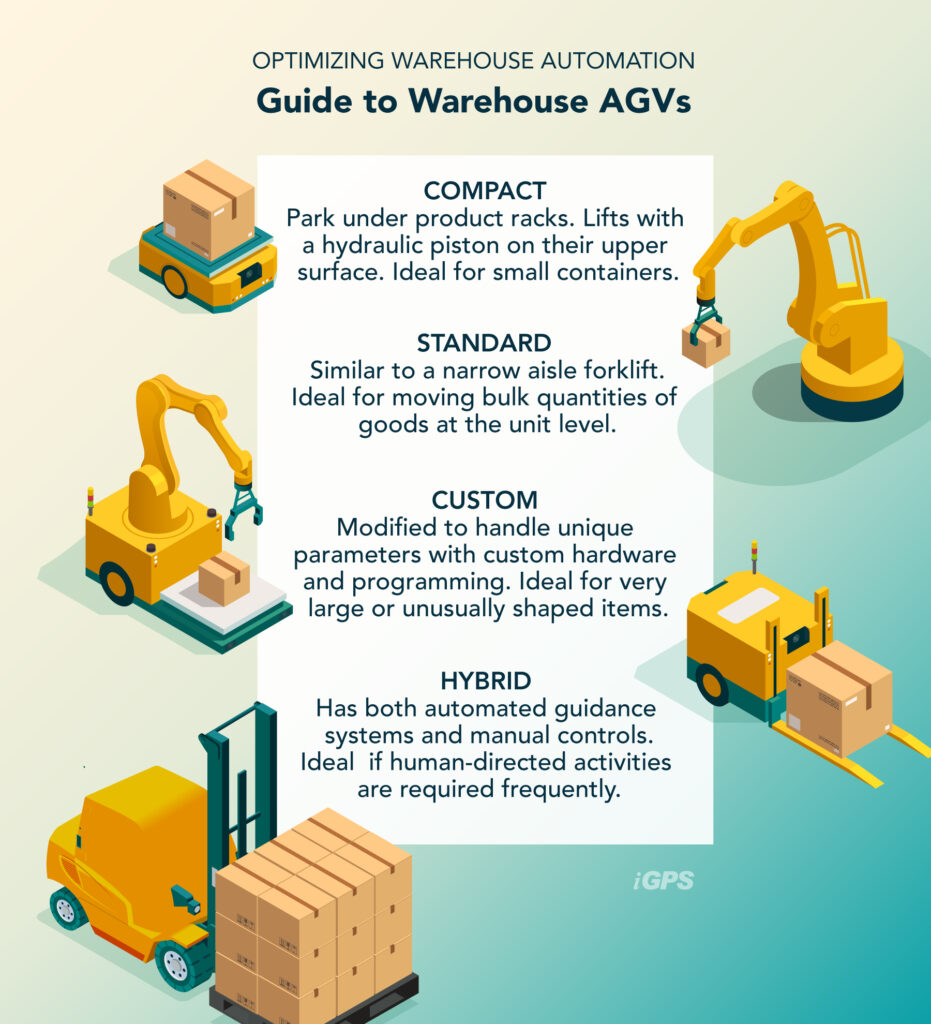

AGVs come in a variety of forms and sizes to handle the wide variety of goods that make their way through a facility. They generally fall into the following categories:

- Compact: This is a small AGV that is just big enough to do its job. Compact AVGs resemble oversized Roombas. The most common models park themselves beneath product racks and lift the whole rack with a hydraulic piston on their upper surface. They’re mainly suited for use with small containers.

- Standard: A standard sized AGV is comparable to a narrow aisle forklift, and usually has a similar array of attachments like forks, clamps, and rollers. This size category of AGV is suitable for moving bulk quantities of goods at the unit level.

- Custom: Some products may be very large or unusually shaped and can’t be handled with typical loading equipment. For a cost, standard AGVs can be modified to handle unique parameters with custom hardware and programming.

- Hybrid: Some companies need to be able to pull an AGV out of its pre-programmed routine and use it for human-directed activities. A hybrid AGV has both automated guidance systems and manual controls designed to be used by an employee. An enterprise implementing an AGV warehouse process may want to consider a few of these for generalized use.

The type of AGV most relevant to you depends largely on what type of product you’re moving and what part of the facility you wish to automate. A compact AGV might be ideal for moving containers of goods from a processing area to a packing area but won’t be able to move those goods when they’re packed on pallets. A standard AGV equipped with a forklift may be useful in multiple areas of the warehouse, but too industrial to go into food or pharmaceutical processing areas. Therefore, it is important that logistics managers take the time to ensure the AGV they choose is able to integrate with the floorplan, existing processes, and the rest of the supply chain.

Choosing AGVs for Your Supply Chain

The first step to bringing AGVs into a facility is to consider the processes that you can reasonably automate with an AGV and build your implementation plan around those. If your company specializes in small batch orders sent directly to the consumer via package, a compact AGV might work best to run batches from manufacturing to packaging. If the warehouse in question specializes in large loads as part of a nationwide distribution network, then standard sized AGVs equipped with forklifts are likely the best option.

Whichever you pick, you’ll want to keep in mind that choosing AGVs that aren’t able to work with pallets will likely create an extra step in the supply chain since at some point products will have to be palletized before they can be delivered to market. Choosing pallet-based AGVs guarantees interoperability across your supply chain and as your company expands into new markets. It also means that you can reuse the automation plan for one warehouse in other facilities with minimal adjustment. Pallet-based warehouse automation does come with its own challenges, however.

Integrating AGVs in the Warehouse and Supply Chain

When considering integrating AGVs into a warehouse or fulfillment facility, managers may be wary of purchasing additional equipment for fear of complicating integration further. However, if using wooden pallets, switching to a shipping platform that is better suited for use with automated systems can make AGV integration much easier and help make the most of supply chain automation. For example, plastic pallets over several advantages over wooden pallets when using with AGVs:

- Built-In Tracking: Some high-quality plastic pallets come equipped with a Global Returnable Asset Identifier (GRAI) number that can be used to track the pallet through the supply chain. It can be read by AGVs either by scanning or radio frequency identification (RFID) and the AGV now knows where the pallet belongs.

- Durability: A plastic pallet is tougher than a wood pallet and capable of making 80 to 100 trips (actual trips, not lab testing) through the supply chain, while a wooden pallet has a lifespan of only about 20 trips. Greater durability translates to greater reliability, which is important for automated systems that operate without constant human oversight

- Consistency: As an engineered product manufactured to meet exacting standards, plastic pallets are consistent in both weight and dimensions and, without loose boards or protruding nails, are easier for pre-programmed AGVs to handle.

- Interoperability: Along with all of the automation-friendly features, plastic pallets meet Consumer Brands Association (CBA) specifications, ensuring that loads are interoperable across the entire supply chain whether it’s fully automated or not.

Implementing AGVs in your facility should involve considering how AGVs will interact with existing processes and equipment. The wood pallets found in most warehouses were developed to work with human-operated forklifts, and don’t have the reliability or consistent dimensions needed to operate satisfactorily within automated processes. As you invest in warehouse automation, consider a durable, precise plastic shipping platform to get the most out of your AGVs.

AGVs are rapidly reshaping the industry. And as technology continues to advance, the role of AGVs in facilities is likely to expand, and their impact on streamlining operations will only grow. Businesses that embrace this technology can look forward to a future of increased competitiveness and productivity, while also contributing to a safer and more efficient working environment.

Companies looking to streamline their facility automation should consider using iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable plastic pallets flow seamlessly through warehouse automation systems and reduce Total Cost of Business. For more information, contact us at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page.

Image 1: Flickr User PEO ACWA