ARTICLE UPDATED ON JUNE 28, 2023

CBA Pallet Grades: How and Why Are Pallets Graded?

In the early 1920’s, shortly after the modern forklift was developed, the first pallets also emerged — transforming the way products were stored at that time. Years later, during World War II, pallets evolved even further. The wood pallet — at the time a revolutionary concept, housed in a 48”x48” square — carried most of these goods to battlefronts around the world. After the war, the pallet concept was applied to civilian products, and a transformed global supply chain was the result. It fell to local trade and manufacturing associations to develop shapes and sizes for these pallets, and later the International Organization for Standardization (ISO) recognized the six most successful of these pallet sizes as ISO standard pallet dimensions. In North America, the most common pallet is the standard 48”x40” spec pallet as standardized by the Consumer Brands Association (CBA), formerly known as Grocery Manufacturers Association (GMA). This pallet is used everywhere from the grocery industry to the construction field.

The majority of standard CBA pallets are made out of wood that wears down over time and can cause machinery and product damage by splintering and breaking — subsequently becoming a hazard for employees as well. To ensure that manufacturers and retailers could demand a minimum quality from their pallets, the industry created CBA pallet grades. The grades provide a way to rate pallets based on their condition and state of repair. To understand how pallets are graded, though, one needs first to understand how pallets are built, the sort of damage they’re subjected to, and how the damage is repaired.

Understanding Pallets

A standard pallet consists of three basic parts: a top deck, a bottom deck, and wood boards or blocks sandwiched between the two decks. The dimensions of the wood vary significantly depending on the quality of the pallet. Higher-quality pallets will have thicker dimensional wood and more deck boards than lower-quality pallets. Pallets intended for reuse generally have more deck boards and replace the wood boards in between the decks, known as stringers, with more substantial 4”x4” wood blocks. Although these reusable pallets are sturdier than single-use platforms, they still suffer damage and require repair, especially after several trips through the supply chain. There are a few basic repairs frequently made to wood pallets:

- Replacement Boards: Deck boards may be frayed and splintered by friction between the product load and the surface of the wood. Heavy weight, combined with movement by heavy machinery, can even break boards. When this happens, the damaged deck board can be pulled off and replaced with a new board, and the pallet will be put back in service.

- Plates: If the stringer or block between the two decks cracks, it is not typically cost-effective to replace it. However, to repair it, a plate with cleats must be hammered over the damaged part of the wood to hold the separating pieces together and keep the crack from spreading further.

- Plugs: When a board breaks or cracks all the way through, a second board 6 to 24 inches in length can be nailed in place beside the damaged board to reinforce the section and keep the pallet in service. This second board is called a plug or a companion stringer.

The CBA pallet grade assigned to a pallet is mostly determined by the type and number of repairs it has had throughout its lifespan. For example, a repaired pallet isn’t going to receive top grades due to its appearance, even if it is still usable.

CBA Pallet Grades

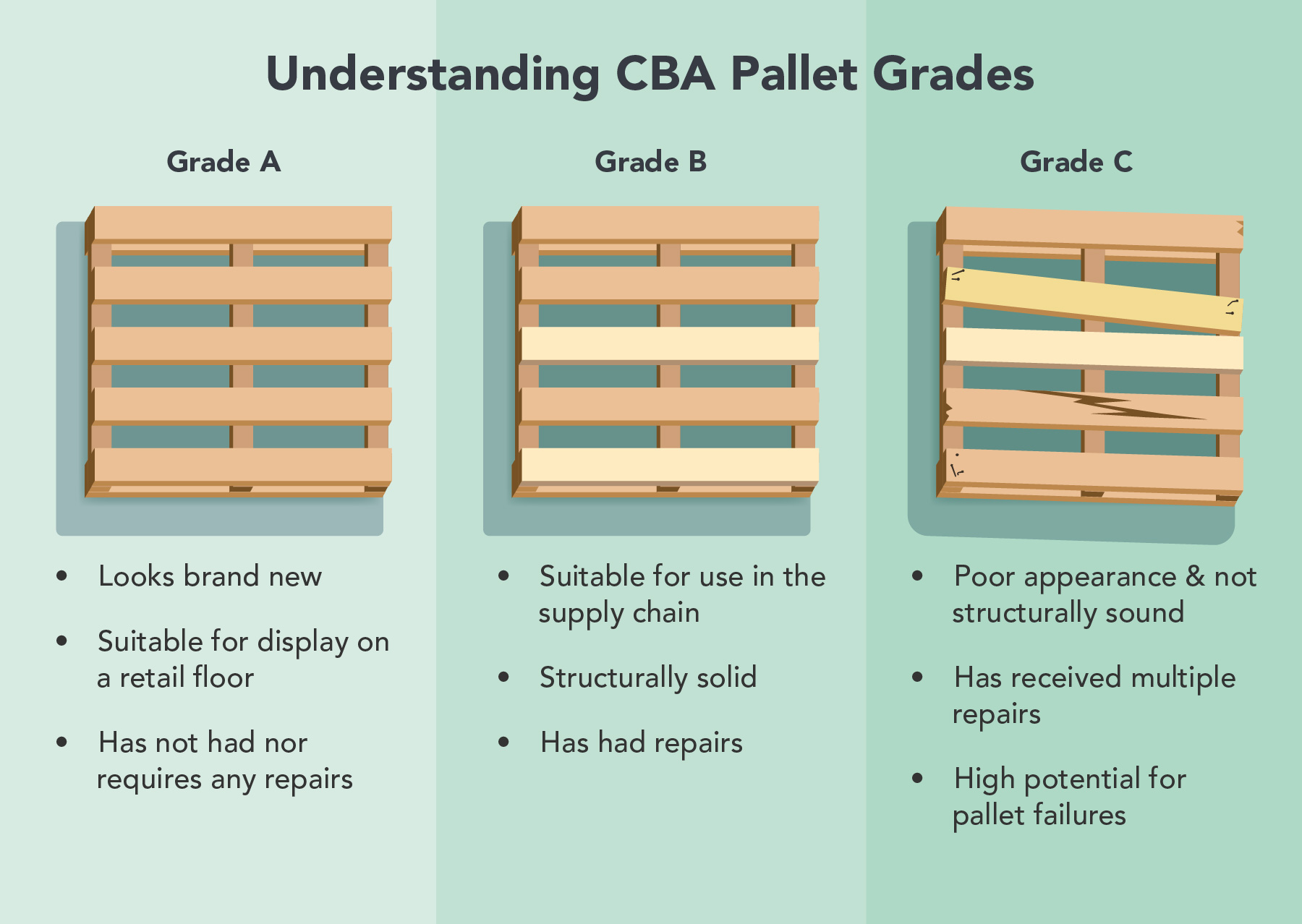

Wood pallets are generally placed into one of two grades, though some sellers use a third grade, but pallets in this grade are typically toward the end of their useful life. Each of these grades is broken down further into categories with more specific criteria:

- Grade A: Also known as grade 1. Generally speaking, Grade A pallets have not had and do not require any repairs. At the top of the grade A category are AAA or “club grade” pallets, which are in good repair, look brand new, and are suitable for display on a retail floor. At the lowest tier of the category are pallets that do not have or need repairs, but may need some soon.

- Grade B: Also known as grade 2 pallets. Grade B pallets have had repairs in the form of replaced deck boards, plates, or plugs. They should be just as strong and reliable as Grade A pallets, but retailers may not want to display them.

- Grade C: Also known as grade 3. Pallets in this tier have a poor appearance and are typically in bad condition. These pallets have typically received multiple repairs and deck boards may not be fully intact. The potential for a pallet failure is relatively high at this CBA pallet grade; therefore, many pallet sellers do not offer this tier.

It is important to note that within each pallet grade, there is a large degree of variation among pallets. After all, pallet grading is subjective – a top-tier pallet is simply one that has not needed repair yet and is therefore graded on looks alone. For example, there’s no guarantee that a visible stain wasn’t missed when the pallet was inspected before it was shipped out, and there’s no foolproof way of telling whether a board or stringer is about to break. Much of this variation is due to the unpredictability of the wood used to make pallets, which has led many in logistics and transportation to look for a more consistent and reliable pallet material.

CBA Spec Food Grade Pallets

Because of the unpredictability of wood, CBA spec plastic pallets have been gaining popularity, especially for food, pharmaceuticals, and other sensitive product loads. Pallets made of plastic don’t have the same variability that wood pallets do, and they perform consistently for much longer. Unlike wood, plastic is non-absorbent, doesn’t stain easily, and cannot absorb bacteria or chemical contaminants. Plastic pallets won’t easily crack or splinter when handled by forklifts or automated machinery. In fact, it’s very difficult to damage a plastic pallet, and as a result, they don’t need the additional clarification of CBA pallet grades. Instead, they are in a category of their own, unofficially called “food grade pallets”, due to the importance of quality pallets for food manufacturers. For them, if a shipment arrives to a retailer in a pallet that is deemed unsatisfactory, food manufacturers can anticipate fines and in some cases, the entire shipment may be rejected.

Many retailers today follow the CBA recommendations for pallet grades and choose their shipping partners accordingly. Manufacturers that select high-quality shipping assets will benefit from increased safety and durability in the long term.

Companies seeking the highest-quality and most durable option available choose iGPS plastic pallets, which are lightweight, recyclable, easily sanitized and not easily damaged. For more information, contact us at 1–800-884-0225, email a specialist at switch@igps.net, or visit our contact page.