ARTICLE UPDATED ON JULY 28, 2023

Stacking loaded pallets correctly is crucial to preventing warehouse accidents and injuries. According to the Occupational Safety & Health Standards (OSHA) guidelines, materials should be stacked, blocked, interlocked, and limited in height to secure them and prevent sliding or collapsing. Incorrectly stacked loaded pallets pose a serious risk to employee safety and increase the chance of warehouse injuries. In 2022, OSHA launched a five-year initiative across several U.S. states specifically aimed at reducing injuries in warehousing storage and distribution.

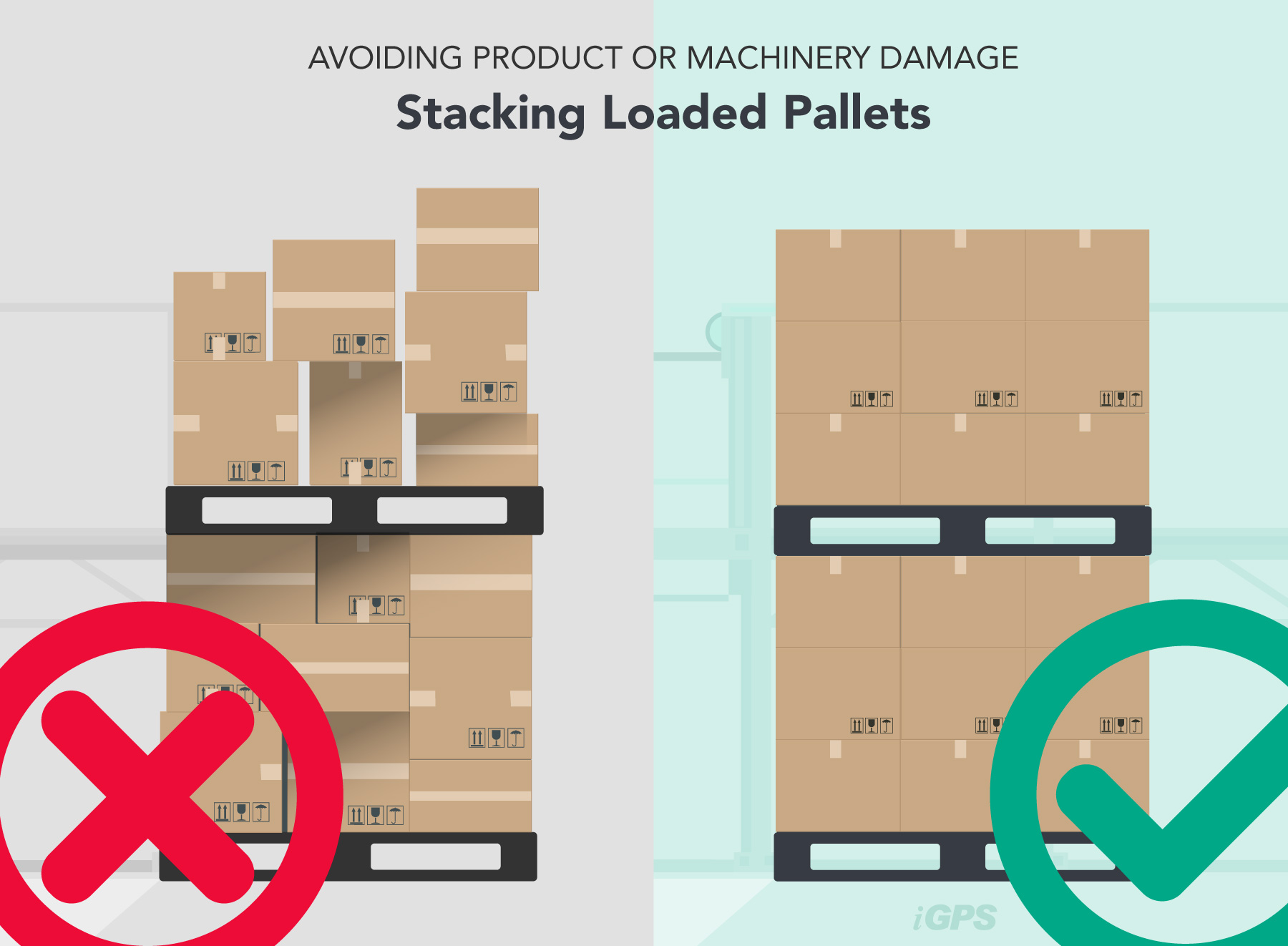

When stacking loaded pallets, pallet load stability is also important to ensure minimal product damage. During handling and transportation, loosely wrapped pallets with an uneven weight distribution can cause products to shift. Stacking such pallets can make the entire load topple, causing significant product damage and ultimately leading to a potential increase in the enterprise’s total cost of business (TCOB). Therefore, it is critical for warehouse managers to properly train their warehouse employees, and ideally to use technology that can assist with the pallet stacking process.

Considerations for Stacking Loaded Pallets

Once a pallet is loaded it can become unstable for several reasons, including exceeding pallet weight limits, uneven weight distribution, being unwrapped or improperly wrapped, or not fully utilizing pallet space. One single unstable pallet can bring down a whole stack and cause expensive damage to products as well as facility machinery. There are a few key considerations to keep in mind while stacking loaded pallets:

- Keep the heaviest pallet at the bottom: The heaviest products should always go on the bottom of the pallet. To that end, the heaviest pallet should also be at the base of a stack to support the weight of several loaded pallets at once. The heaviest pallet lowers the center of gravity for the entire stack and offers a stable base.

- Use a pallet storage method: In warehouses and storage facilities, pallet storage methods play an important role in optimizing space. In the commonly used block-stacking method, in which loaded pallets are stacked on top of each other without using any specialized equipment, pallets must be in good condition; otherwise the entire stack can become dangerously unstable. To increase the stability of loaded pallet stacks, the double-stacking method can be used, in which lifting aids such as stabilizers or bars are placed between the pallets to create more stability.

- Stack pallets evenly: Product items sticking out or overhanging at the edges of a loaded pallet can pose a safety hazard. Such pallets can cause a stack of loaded pallets to tip over. As a result, when block stacking loaded pallets, it’s crucial to ensure that pallets are evenly stacked and that no products extend past the edges of the pallet.

- Follow a stacking pattern: Pallets are usually stacked with products in either a columnar-aligned pattern or interlocked stacking pattern. When products on a pallet are stacked in a columnar manner, product cartons are placed one over another until the prescribed stack height is reached. Pallets stacked this way have greater compressive strength and, as a result, are a better choice for pallets that will be stacked on top of each other.

- Inspect the condition of pallets: Though a routine inspection of pallets before loading and after unloading is standard practice across facilities, reused wood pallets should be inspected with particular care. The presence of any protruding nails or splinters on the surface of these pallets can puncture the plastic wrap that binds the entire load together, causing the load to shift and the stack to become unstable. Warped or broken deck boards can also cause instability in the pallet load.

The type of pallet also plays a major role in maintaining the stability of a pallet stack. Wood block pallets, for instance, typically have a static load capacity of 5,500 pounds, yet this capacity decreases as the wood degrades with reuse. Additionally, loading a worn wood pallet to its maximum load capacity might cause it to collapse. Switching to plastic pallets can help address this persistent problem.

Using Plastic Pallets to Create a Stable Stack of Loaded Pallets

When it comes to creating a stable stack of loaded pallets, plastic pallets have a few major advantages over conventional wood pallets:

- Accurate maximum load capacity: A high-quality plastic pallet has a maximum static load capacity of 30,000 pounds – this number is stable and does not change over time. This accuracy makes it possible to load pallets up to their maximum capacity without the risk of pallet damage or failure.

- Unmatched durability: The non-porous plastic surface prevents moisture accumulation, rot, or mold and increases the lifespan of a plastic pallet. The durability of a plastic pallet also provides an accurate maximum edge-rackable load of 2,800 pounds.

- Consistent size: The uniform dimensions of a plastic pallet and the absence of any splinters or nails on the surface make it easy to stack loaded pallets in an even and stable formation.

The durability, light weight, and consistency of plastic pallets make them easy and safe to stack, reducing the risk of injuries to warehouse employees, machinery wear-and-tear, and expensive product damage. For enterprises of every size, switching from wood pallets to high-quality plastic pallets means reducing the overall cost of business and increasing profit margins and worker safety.

Companies looking to safely and efficiently stack loaded pallets use iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable plastic pallets incorporate RFID technology, making them traceable throughout a supply chain. For more information, contact us at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page.