When selecting a pallet supplier, supply chain managers must consider a multitude of factors. Opting for the incorrect supplier can result in problems that impact every facet of a business, whereas making the right choice can significantly enhance the efficiency of the supply chain and financial outcomes.

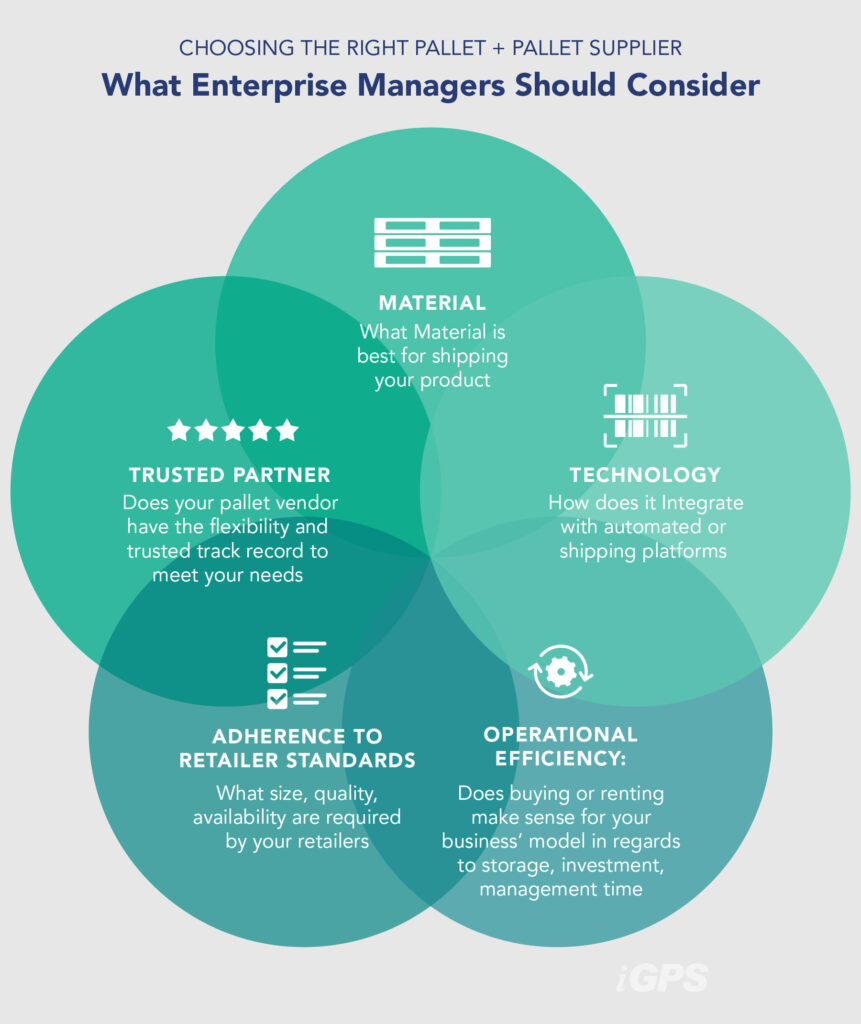

When choosing the right pallet supplier, there are a few key considerations enterprise managers should keep in mind:

- Reliability: Choosing a pallet supplier that puts the needs of your business first is critical to a successful partnership. Delivery times are vital for suppliers, and businesses need to be able to rely on their services. When looking around, consider asking potential pallet suppliers if they can provide you with customer feedback to ensure they have a positive track record. Situations may arise that are beyond the control of both parties, so a vendor with flexibility and a history of meeting client needs is key.

- Adherence to standards: Large companies such as Walmart keep to specific supplier standards for shipping, storing, and displaying products. These guidelines are in place to maintain quality assurance and meet customer demand throughout the supply chain. Therefore, it is important that a pallet supplier is educated on the various standards and able to adhere to them.

- Commitment to innovation: Find an innovative supplier that will work with you to build a stronger, smarter supply chain. Look for intuitive tools, such as RFID technology, artificial intelligence, as well as online pallet ordering and forecasting portals, to help ensure you have the pallets you need when you need them. The right supplier can help to optimize logistics with leading-edge technologies, such as the track and trace systems used by iGPS.

- A pooling vs. sales-focused model: While there may be rare instances in which it makes sense for a manufacturer to own pallets, virtually all enterprises will benefit from a pallet pooling model, in which they rent pallets from a trusted supplier. This boosts efficiency and reduces empty truck miles while eliminating the headaches of purchasing, storing, inspecting, and maintaining a fleet of pallets.

Choosing the right pallet and pallet material:

Of equal importance to the supplier itself is the choice of pallet material. Choosing the right pallet for a company’s shipping needs is necessary to ensure the safe delivery of products and to meet customer demand. With a variety of available sizes, as well as numerous styles and materials, manufacturers may find themselves wondering which pallet will best suit their needs.

- Wood: The most conventional pallet type, wood pallets can be useful for transporting heavy loads and are often easy to repair. However, wood pallets typically need to be replaced more frequently than those made with other materials. Due to their porous nature, they are difficult to keep clean and can harbor bacteria. They also are prone to splintering, which can lead to accidents that disrupt the supply chain and put products and workers at risk. Wood nails and splinters can also jam up equipment and create messy workspaces.

- Metal: Often made of aluminum, carbon steel, or stainless steel, metal pallets are mostly used for heavy load capacity. They are very hygienic and easy to sterilize. However, when exposed to the elements, some metals may begin to rust, which can jeopardize products along the supply chain. Their added weight also leads to greater fuel usage, which impacts both the environment and the bottom line for businesses.

- Plastic: Plastic pallets are durable and weigh significantly less than wood or metal. Additionally, they have a uniform shape that pairs easily with automated systems. Reusable, pooled plastic pallets such as those made by iGPS offer clear environmental advantages that align with business sustainability goals. For example, after a short lifespan of about 25 trips, wood pallets need to be repaired or discarded, and often due to the high cost of repair they end up in a landfill. Plastic pallets, on the other hand, complete an average of 100 trips across the supply chain before they are recycled and made into new pallets.

As the demand for efficiency in the supply chain continues to grow, so does the need for sustainable options, durable materials, and increased integration between shipping platforms and automated systems. Choosing a pallet supplier that offers an exceptional product combined with a commitment to customer service and innovation is imperative for the success of today’s supply chain stakeholders.

Companies committed to choosing the right pallet supplier use plastic pallets from iGPS. They are lightweight, recyclable, and help streamline your supply chain. For more information, contact us at 1-866-557-0047, email switch@igps.net, or visit our contact page. We also invite you to follow us on LinkedIn. et supplier use plastic pallets from iGPS. They are lightweight, recyclable, and help streamline your supply chain. For more information, contact us at 1-800-884-0225, email switch@igps.net, or visit our contact page. We also invite you to follow us on LinkedIn.