Key Takeaways:

- Deadhead trucking constitutes 35 percent of wasted capacity, accounting for 61 billion empty miles annually, which pallet pooling can significantly reduce, enhancing efficiency and profitability.

- Less deadhead trucking translates to lower fuel consumption and CO2 emissions.

- Pallet pooling transforms unproductive empty pallet trips into revenue-generating ones, helping businesses save on fuel and rental costs.

- Pallet pooling eliminates the need for companies to manage their own pallets, streamlining operations and allowing businesses to focus on transporting products.

Deadhead Trucking: Avoiding Empty Miles

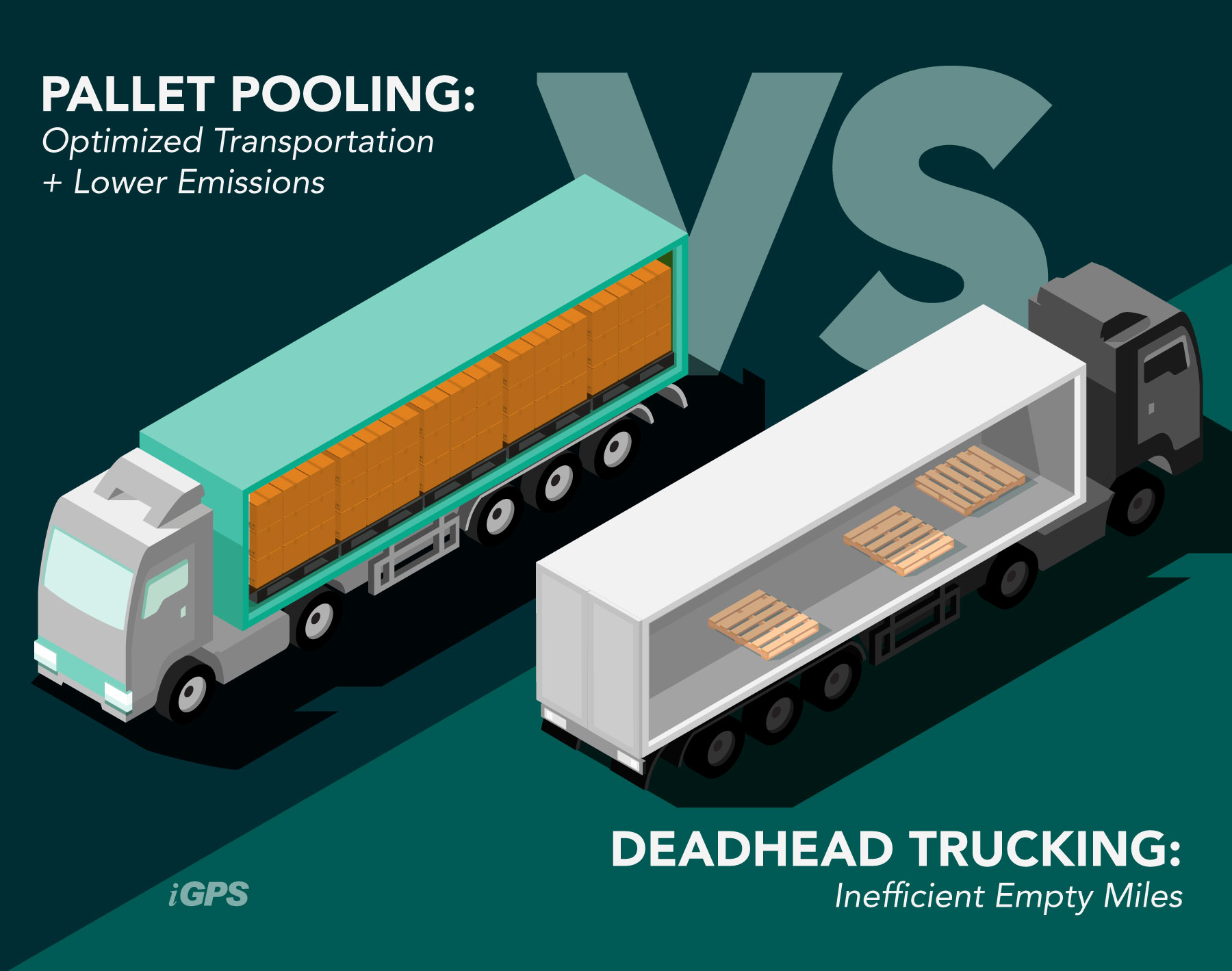

In the world of logistics, empty miles are a constant headache. We’re talking about deadhead trucking, those big rigs cruising down the highway with no cargo. This translates to lost revenue – the truck isn’t generating income while it burns fuel. Deadhead trucking is the epitome of supply chain inefficiency. Logistics managers who can slash these empty legs stand to see real savings.

Empty miles, or deadhead trucking, cost the trucking industry billions due to wasted capacity. Pallet pooling services can offer a solution. By partnering with a provider, companies can eliminate deadheading associated with returning used pallets, freeing up space for revenue-generating cargo. Some pooling companies even incentivize transporting empty pallets to depots or retailers, turning them into a “load” that offsets fuel costs. This approach aligns with the growing trend of optimizing transportation for full and empty loads, leading to increased efficiency and profitability for carriers and shippers.

Transporting Pooled Pallets to Earn Money on a Dead Leg

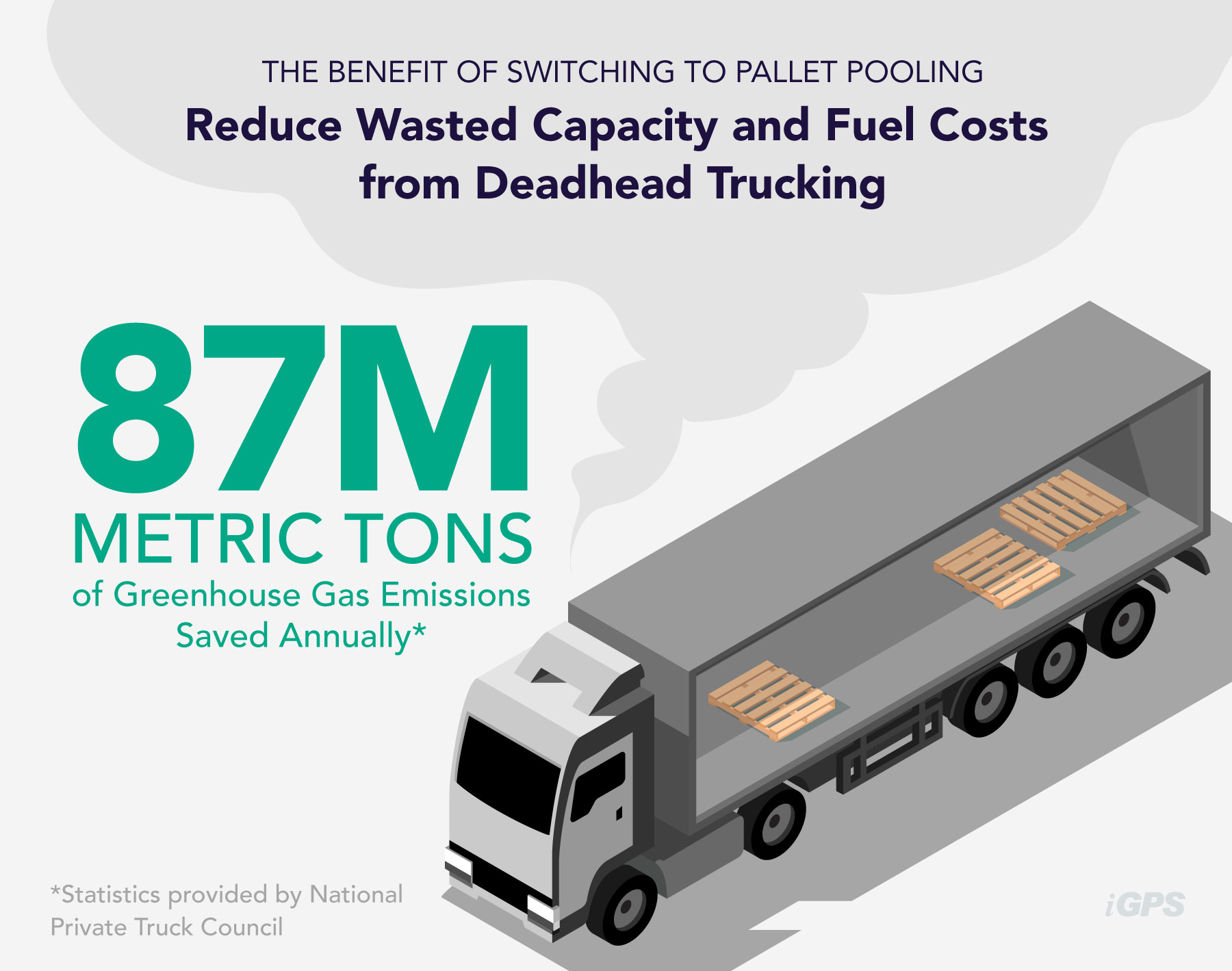

Pallet pooling services tackle a hidden cost in the supply chain: empty miles from returning used pallets. These miles, according to a recent Convoy report, account for a whopping 35 percent of wasted capacity. This accounts for 61 billion empty miles and 87 million metric tons of unnecessary annual emissions, according to Trucking Drive.

With pallet pooling, a dedicated service manages a pool of pallets, delivering fresh ones and handling used pallet transport for cleaning and reuse. This eliminates the need for companies to buy, repair, transport, and manage their own pallets, leading to cost savings, improved efficiency, and freed-up resources by eliminating deadhead trucking associated with returning used pallets.

Pallet pooling incentivizes carriers because they could pay a flat fee to transport empty pooled pallets to their depots or designated locations. This approach transforms a previously unproductive journey into a revenue-generating one, helping to offset fuel and pallet rental costs. Furthermore, pallet pooling goes beyond simply mitigating empty miles. The system can prevent deadhead trucking by eliminating companies needing to return used pallets. This frees up valuable truck space for revenue-generating cargo, boosting overall efficiency and profitability for carriers participating in pallet pooling programs.

How Pallet Pooling Can Eliminate Deadhead Trucking

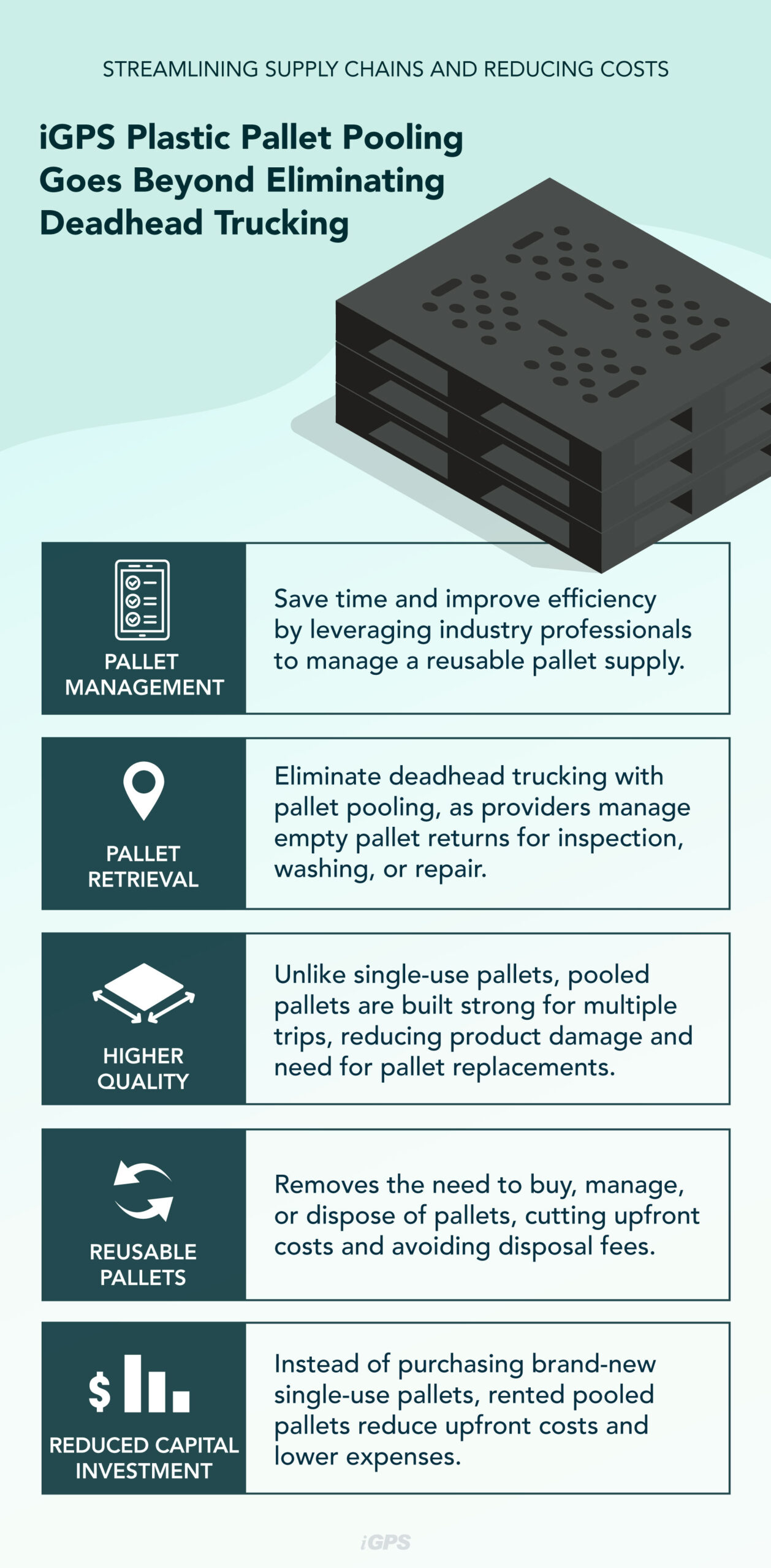

Pallet pooling has become the standard for large national and international corporations whose logistics managers prioritize efficient product distribution and profitability. Instead of managing their supply of single-use or reusable pallets, companies that use a pallet pooling provider can leverage the expertise of industry professionals to manage a reusable pallet supply. This approach eliminates deadhead trucking by transporting empty pallets from retailers back to production centers or depots for inspection, washing, or repair. With the transportation of their empty pallets managed by the pooling provider, businesses can eliminate dead legs, allowing them to focus on transporting their products instead of pallets.

Pallet pooling offers a compelling solution for businesses seeking to streamline their supply chains and reduce costs. Here’s how it goes beyond eliminating deadhead trucking:

- Higher-Quality Pallets: Unlike single-use stringer pallets, pooled pallets are built for multiple trips. They utilize more robust materials and construction techniques, reducing product damage and fewer pallet replacements.

- Reusable Pallets: Pallet pooling eliminates the need for companies to purchase, manage, and dispose of their pallets. Rental eliminates upfront costs, and companies avoid the burden of used pallet transportation and potential disposal fees.

- Reduced Capital Investment: Pooled pallets are rented, meaning companies avoid the total upfront cost of purchasing pallets. The rental cost of a reusable pallet is generally lower than buying a brand-new single-use pallet.

While pallet pooling offers clear advantages like reduced empty miles and lower logistics costs, material matters. Traditional wood block pallets, common with large providers, are susceptible to breakage and generate debris. Additionally, their porous nature makes thorough sanitation difficult, raising concerns for food safety compliance under FSMA regulations. Pooled GMA plastic pallets eliminate deadhead trucking and efficiently comply with food hygiene regulations, significantly reducing the risk of contamination during transportation, whether products are being shipped or empty pallets are being transported for reuse. By utilizing pooled, rented plastic pallets, businesses can achieve the most cost-effective and environmentally friendly solution to eliminate deadhead trucking, ultimately safeguarding their profit margins.

In Summary: Key Q&A

What is deadhead trucking and why is it a problem?

Deadhead trucking refers to the movement of empty trucks or trailers back to their origin after delivering a load. It is a problem because it represents wasted fuel, driver wages, and lost revenue opportunities, significantly impacting the bottom line of logistics operations.

How can pallet pooling help eliminate deadhead trucking?

Pallet pooling helps eliminate deadhead trucking by providing a managed service for transporting empty pallets. This service reduces the need for companies to handle the return logistics of their pallets, freeing up space for revenue-generating cargo and improving overall transportation efficiency.

How does using plastic pallets in pooling programs improve logistics efficiency?

Plastic pallets are lighter and more durable than wood pallets, which reduces transportation costs and improves fuel efficiency. Additionally, plastic pallets are easier to clean and sanitize, making them compliant with food hygiene regulations, thus reducing the risk of contamination.

What cost savings can businesses expect from pallet pooling?

Businesses can save on the upfront costs of purchasing pallets, the expenses associated with pallet maintenance, and the logistics costs of transporting empty pallets. The rental cost of reusable pooled pallets is generally lower than buying single-use pallets, making pallet pooling a more cost-effective solution.

What makes plastic pallets preferable over wood block pallets?

Plastic pallets are lighter, more durable, and easier to sanitize compared to wood block pallets. They meet food hygiene regulations, reduce the risk of contamination, and lower transportation costs due to their lighter weight.

Can pallet pooling contribute to sustainability goals?

Absolutely. By reducing empty miles and promoting the use of reusable pallets, pallet pooling helps decrease fuel consumption and carbon emissions. This aligns with many companies’ sustainability goals and reduces their overall environmental footprint.

Manufacturers looking to reduce deadhead trucking and reduce empty miles can enhance their logistics operations by opting for iGPS plastic pallets. Because manufacturers can rent iGPS pallets, they avoid the total upfront cost of purchasing them. For more information, contact us at 1-800-884-0225 , email a specialist at switch@igps.net, or visit our contact page.