ARTICLE UPDATED NOVEMBER 30, 2023

When comparing hardwood pallets to pine platforms, the typical dilemma revolves around the trade-off between durability and affordability. Hardwood offers superior longevity, while softwoods like pine are inexpensive, often leading to the use of lightweight stringer pallets that are discarded after a single use at the end of the supply chain. However, many supply chain managers are now considering a third alternative: plastic pallets.

Plastic pallets encompass the advantages provided by both hardwood and pine pallets while mitigating the inherent issues associated with wood. High-quality plastic pallets outperform wood in terms of durability and load capacity. Additionally, they support circular business models, as they can be recycled and used to create new pallets at the end of their useful life.

Considering these factors, focusing solely on the choice between hardwood and pine pallets may not be the most informed approach. When considering the strengths and weaknesses of both hardwood and pine pallets, it is easy to see why considering a third alternative, such as plastic pallets, could be a more advantageous option.

Hardwood Pallets vs. Pine: Choosing Between Price and Quality

When comparing hardwood and softwood, it’s important to understand the difference between the two on a basic level. Hardwoods come from deciduous trees that lose their leaves on an annual basis, while softwoods come from trees that stay evergreen. Shipping pallets are usually made either from hardwoods like hickory, mahogany, maple, oak, teak, and walnut, or from various types of pine, which are softwoods. There are many pros and cons to consider when deciding to ship products on one of these woods.

Hardwood

| Pros | Cons |

|

|

Pine

| Pros | Cons |

|

|

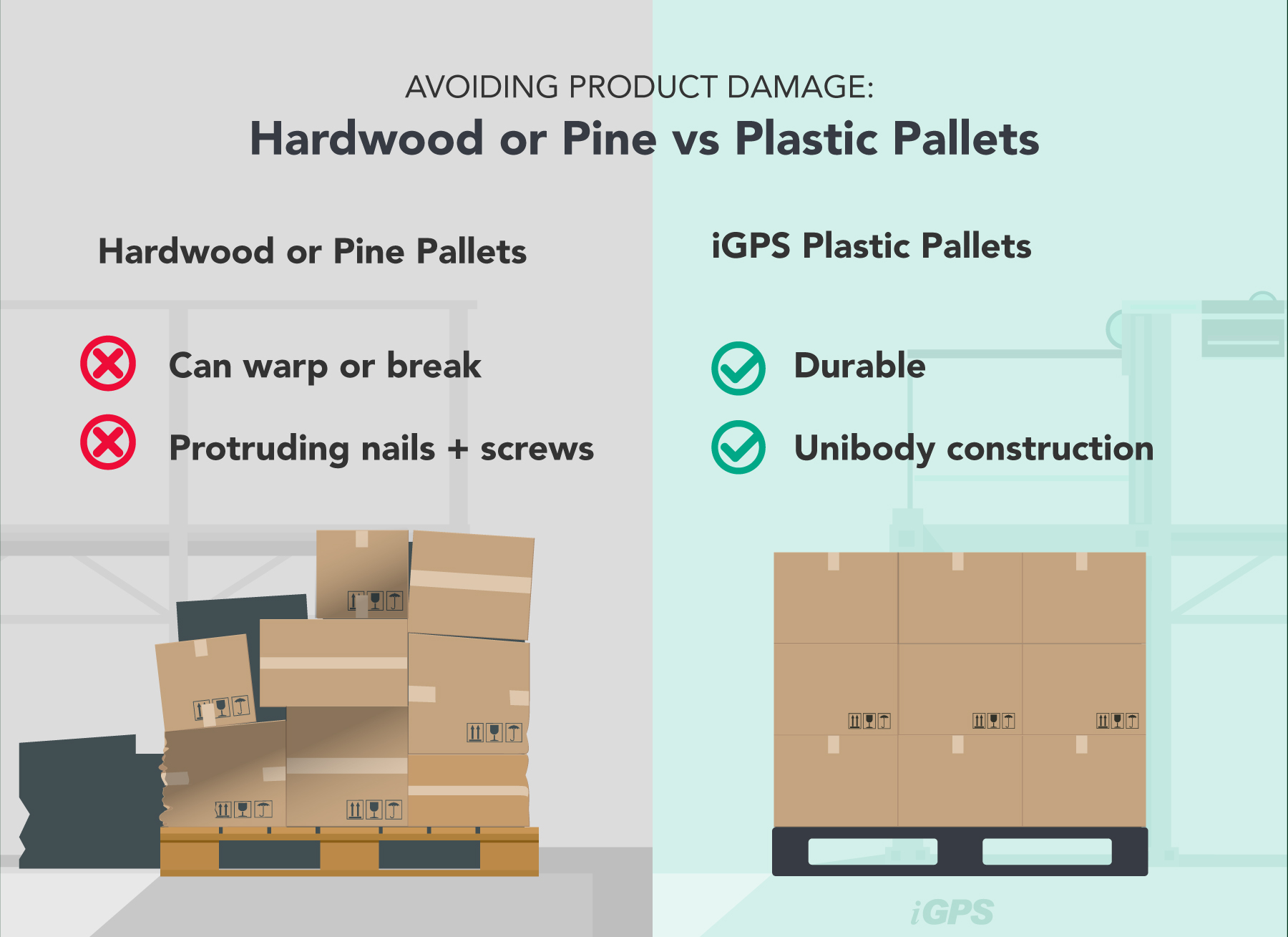

Comparing hardwood and pine pallets reveals that, while they each may have their own unique benefits, they also have many of the same drawbacks. When it comes down to it, pallets made of both types of wood can warp and break – even hardwood – and both can damage equipment when nails and screws come loose from a pallet. And no matter which type of wood a block pallet is made of, it will always be heavy, weighing as much as 75 pounds. For these companies, those looking for a lighter, cleaner, and more durable pallet might consider an alternative material that is rapidly growing in popularity: plastic.

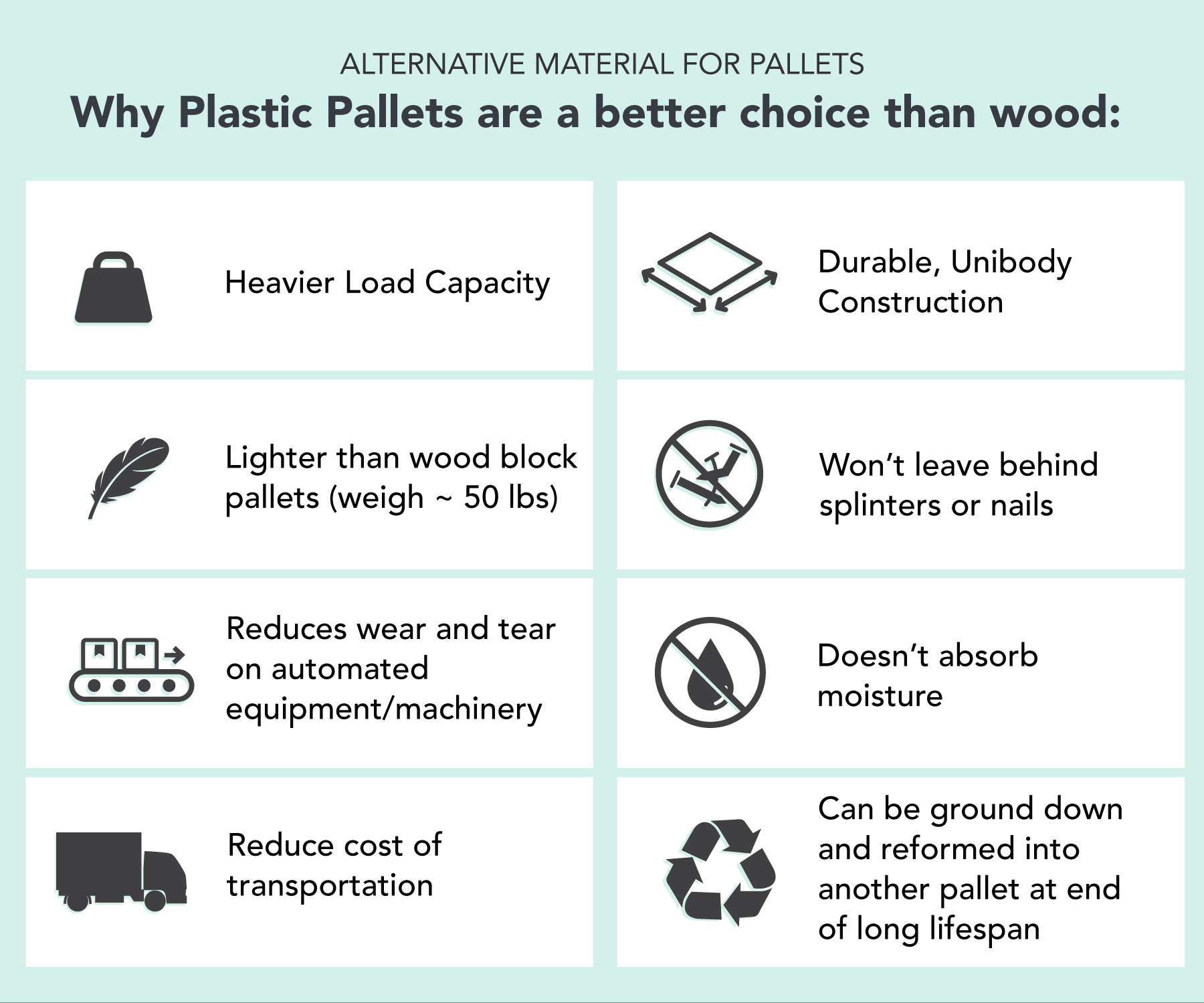

Why Plastic Pallets Are Superior to Wood

A high-quality plastic pallet can hold a heavier load than even the best wood block pallets. In some cases, plastic pallets can carry as much as 5000 pounds of dynamic weight and 2800 pounds edge-rackable. Additionally, they are lighter than their hardwood counterparts, usually weighing around 50 pounds, which makes them easier for employees to move and stack, reduces wear and tear on automated equipment and machinery, and can help reduce the cost of transportation by ensuring that sellable products make up more of the weight of each truckload.

The use of plastic pallets also eliminates the issue wood pallets have of leaving behind splinters that can damage products and packaging or injure workers. Plastic pallets have a unibody construction, meaning they are fused and don’t require nails or screws. And because plastic doesn’t absorb moisture, it does not rot, mold, or mildew, and is easy to clean and sanitize. Plastic also works to make supply chain management more efficient by reducing waste. At the end of its lifespan, a plastic pallet can be ground down and reformed into another pallet, making it a recyclable and sustainable choice.

With all that said, the price point is often the deciding factor for companies comparing pallet options, and in some cases, inexpensive pine stringer pallets may be the best option for certain loads. However, for most enterprises, high-quality plastic pallets will offer the best value through long-term cost savings because of their durability, longevity, lighter weight, and other benefits. Supply chain managers who wish to enhance those cost savings should consider the benefits of renting, rather than owning, their pallets. Plastic pallet pooling programs, such as the one offered by iGPS, take on the responsibility of maintenance and replacement of pallets, which eliminates the need for a business to repair or store large numbers of pallets.

Companies looking to make the switch to plastic pallets should consider iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable plastic pallets incorporate RFID technology, making them traceable throughout a supply chain. For more information, contact us at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page.