Pallet pooling allows multiple companies to share reusable pallets. A provider rents out pallets to businesses, which use them for shipping and return them after use. The provider inspects, repairs, and redistributes the pallets. This system reduces costs, improves efficiency, and minimizes waste, as companies avoid purchasing, maintaining, and storing their own pallets.

If you’re a stakeholder in the consumer packaged goods industry, chances are that your products are traveling from the manufacturing facility to a retail location for sale on a daily basis. Finding a cost-effective method to return them to the beginning of the supply chain for reuse can be a daunting task. The process of sorting, stacking, and returning pallets to a central depot (or disposing of pallets that can no longer be used) can be quite a hassle, all while trying to minimize expenses.

Perhaps you’ve even wished that resourceful DIY enthusiasts would come by and “reclaim” the used pallets, saving you the trouble of disposing of them. These challenges are commonly faced in the supply chain, but viable solutions exist. One such solution that many companies rely on for efficient pallet management is engaging a pallet pooling provider. So, how exactly does pallet pooling function, and what advantages does it offer?

Benefits of Pallet Pooling

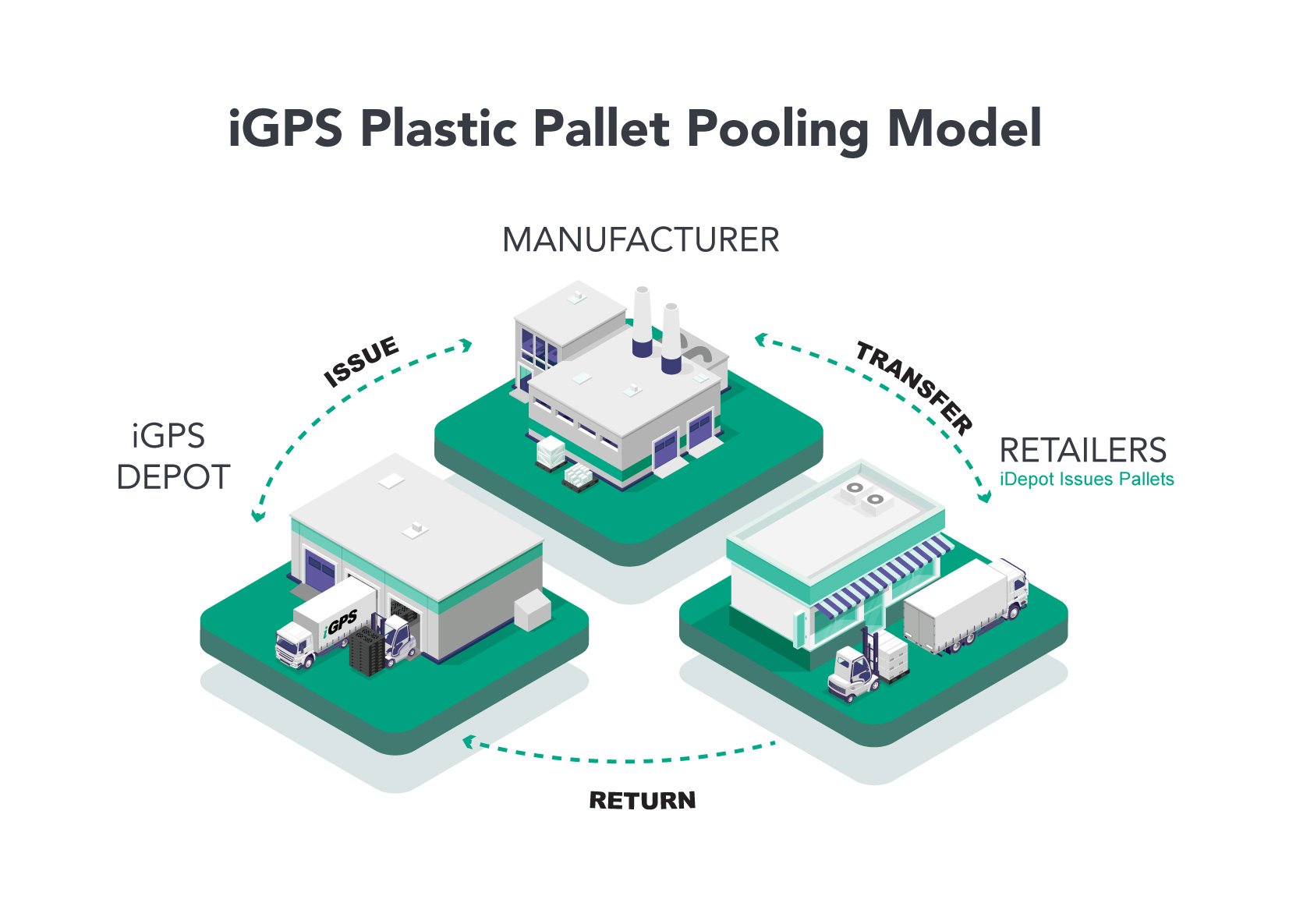

A pallet pooling service provider takes charge of your pallet management. Instead of purchasing their own pallets, manufacturers can opt to rent them from a shared pool. The pooling company ensures that a sufficient number of pallets, in good condition and ready for use, are delivered to facilities whenever they are needed.

They handle the logistics of transporting the pallets that have been used either to other businesses or back to the production facilities. This reverse logistics process ensures that the pallets are recovered and made available for reuse.

By relieving a company of the burden of managing its own pallet supply, a pallet pooling program simplifies the complexities associated with pallet procurement, management, and recovery. As a result, it minimizes waste and effectively reduces the Total Cost of Business (TCOB).

Read more about the benefits of pallet pooling.

Why Choose Pallet Pooling?

Companies that choose to use reusable pallets and manage them in-house are essentially operating two separate businesses, as well as a parallel supply chain, just to provide their product with a shipping platform. Running a parallel operation adds significant transportation and labor costs to a company’s expenses, and it’s possible that reusable pallets may even end up competing with products for transportation and storage space. The result of managing one’s own pallet fleet is potentially a waste of valuable time and resources, and a distraction from the core business operations.

To avoid dealing with the transportation and management of reusable pallets, some companies choose to use basic one-way stringer pallets. These come in various pallet grades that are mostly based on how many trips they’ve made through the supply chain. The best of these, a so-called “club grade” pallet, is one that has never been used, has had no repairs, and is available for a premium price. Unfortunately, companies may end up paying that premium price over and over again just to ensure that end retailers will accept their pallets.

That’s because it is increasingly common for retailers to set quality criteria for the loads they receive from their suppliers, and one of these criteria is pallet quality. Club grade pallets take their name from the way club stores often display products for sale directly on the pallets they arrived on. These retailers — which are some of the largest in North America — don’t want their customers to be less inclined to purchase a product because of a stained or visibly degraded pallet. They often reject loads on the basis of pallet quality, and will look for new suppliers if a vendor disrupts their operations by repeatedly shipping them pallets of unacceptable quality.

The sturdiness of reusable plastic pallets makes them less likely to be rejected by retailers. But getting the most out of reusable pallets requires setting up a network to collect the pallets, sort them, repair them, and send them out again. Pallet pooling takes care of this for customers, allowing them to do away with the costs of additional storage and maintenance facilities and the staff for those facilities. Transportation costs are also reduced, since a pallet pooling service involves fewer dead legs and loads that consist of nothing but pallets.

Renting pallets from a shared pool offers substantial savings and a significant return on investment, which explains its adoption by most major manufacturers and suppliers. However, not all pallet pools are created equal, and those based on reusable wood block pallets still have issues, including acceptance by retailers.

Choosing a Pallet Pool that Works for You

Most pallet pooling services offer reusable wood block pallets. While much of the supply chain has traditionally been built around wood pallets like these, rising transportation costs, tightening quality standards, and the need to improve efficiency are starting to make reusable wood block pallets unappealing to companies. The disadvantages of reusable wood pallets include:

- Product Damage: Wood boards can be broken without much trouble by heavy machinery in the supply chain or during transportation, and this can be exacerbated by multiple uses or touches through the supply chain. While the pallet may remain mostly usable, rough edges, surfaces, and splinters from a damaged pallet can tear or puncture product packaging, rendering it unfit for sale. Over time, a wood block pallet will also likely lose its original geometry and weight, impairing the efficiencies of highly automated manufacturing and warehousing systems.

- Debris in the Warehouse: When a wood pallet is damaged, sometimes wood pieces, splinters, sawdust, and nails are left behind. These can cause foreign object contamination in food products, or they can accumulate in work areas, making it more difficult to keep the warehouse clean and creating a safety hazard for employees and equipment.

- Unhygienic: A wood pallet cannot be easily washed or sanitized. Although they are sometimes heated-treated in a kiln before being shipped out, wood pallets are not cleaned often or at all once they’re deployed in the supply chain. As a result, a wood pallet can easily act as a vector for the contamination of products or production areas.

- Variability: Wood block pallets are subject to a great deal of variation. The wood used in the pallets may have different grains and densities. It can also absorb moisture, which changes the pallet’s weight and tightens the margin of error for loads that weigh out.

- Retailer Rejection: Many of the above disadvantages also play a role in retailer rejection. A pallet that has caused product damage or has contaminated product will be rejected, for instance. But a load shipped on a wood pallet is in general more likely to be rejected by a retailer — sometimes for minor issues —than a pallet made from an alternative material like plastic.

The Ultimate Pooled Platform? Plastic Pallets

In today’s world of tightening quality standards, where profit margins depend on maximizing efficiency, issues with wood pallets can seriously impact a company’s earnings. Fortunately, there is an alternative. Plastic pallets are non-absorbent engineered shipping platforms that meet the same specifications as wood pallets.

They are also sturdier, without variations in weight and dimensions that can throw off shipping margins and cause issues in supply chain automation. A plastic pallet’s smooth, nonabsorbent surface makes it easy to clean between uses, and its durability means it won’t splinter or leave behind debris. The advantages of plastic pallet pooling over wood are such that many major retailers are pushing their vendors to make the switch to this type of shipping platform of the future.

To enjoy the advantages of plastic pallets, companies have needed in the past to procure and manage their own stock of plastic pallets, a big undertaking that brings with it all the challenges and drawbacks discussed above. But, with pallet pooling that is no longer the case. Plastic pallet pooling providers like iGPS specialize in providing companies of any size with a reliable pooled plastic pallet at economic rates, meaningfully driving down Total Cost of Business and removing complexity from business operations.

Pallets no longer need to be a source of stress for manufacturers and retailers. By partnering with a pallet pooling company, companies can save time and resources, while boosting the efficiency of their supply chain.

Companies looking to engage with the most cost-efficient pallet pooling company use iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable plastic pallets incorporate RFID technology, making them traceable throughout a supply chain. For more information, contact us at 1800-884-0225, email a specialist at switch@igps.net, or visit our contact page