Wood—a fundamental component of nearly every early American industry—has been essential to modern shipping and logistics for decades in the form of wood pallets. But just as the homebuilding and ship manufacturing industries adopted stronger materials than wood, the modern shipping industry has likewise evolved. Nowadays, a simple question like “How strong are wood pallets?” can point logistics managers to pallet innovations that are stronger and can lower their total cost of business (TCOB).

How Strong Are Wood Pallets?

There is no one way to address this question since wood pallets are influenced by several variables. Instead, it is better to ask the following two key questions:

- How strong, in theory, is a wood pallet?

- How strong is a particular wood pallet?

These two questions bring a central issue into focus: the wood pallet standard is far different than individual wood pallets in the field. Unless it is 100% brand new, any given wood pallet in a facility has been used, repaired, cleaned, chipped, and more. While the broad question is a good start, logistic experts have to consider specifics.

How Strong is the Standard Wood Pallet?

While there are specialty pallet sizes for some use cases, the standard pooled wood pallet size is as follows:

- Overall size: 48” x 40”

- Weight: 65-75 pounds

In many ways, standard wood pallets are a marvel. While no single piece of wood seems particularly strong, the standard pooled wood pallet has a 2800 pound dynamic capacity.

That’s almost one and a half tons. Of course, that describes the maximum capacity for a pallet in perfect condition, which gets to the heart of the questions above.

Impacts on the Strength of Wood Pallets

A pooled wood pallet direct from the factory has a 2800 pound dynamic capacity, but it is rare to receive a brand-new pallet. As a result, there are related factors one should consider when assessing the strength of wood pallets.

Damage

Wood pallets are relatively easy to damage. This is true if the pallets are handled manually or automatically. When handled manually, their weight (and propensity for splinters) leads to damage from drops and bumps. And in the era of forklifts and increased automation, this is especially true. As huge weights are lifted and moved at high speed, wood pallets can chip, splinter, and crack. Damaged wood pallets are a major cause of rejected truckloads, especially in the grocery and pharmaceutical industries.

Repair

Most people in a warehouse or yard can spot a heavily damaged wood pallet. However, it is more difficult to diagnose the problems that can follow each repair. Every time a wood pallet is repaired, wear and tear on the connections increase. New boards can mix with older ones, and this can create an unstable weight bearing capacity.

While repairing old pallets is a good practice, it increases the difficulty in discerning if the pallet will be able to withstand the rigors of the modern supply chain.

Age

Wood pallets can survive some harsh conditions, but constant wear and tear weakens them. Because of wood’s natural properties, boards can bend when they absorb an impact. This can result in unevenly distributed loads where some areas of the wood pallet will crack because they must support a heavier proportion of the load. Even minor damage weakens the wood pallet, and minor damages add up.

Uneven weight distribution isn’t the only issue for wood pallets as they age, though. Wood pallets are also weakened by water absorption, which can be a factor in contamination as well.

The Move Toward Pallet Efficiency

While new wood pallets can be effective, the rigors of shipping and transport are severe and lead to damage, wear and tear, and uncertainty. Given the speed of modern logistics and the need for to-the-minute efficiency, that lack of an answer raises too many questions.

The elimination of uncertainty and assurance of efficiency are shared goals across logistics, warehousing, and operations.

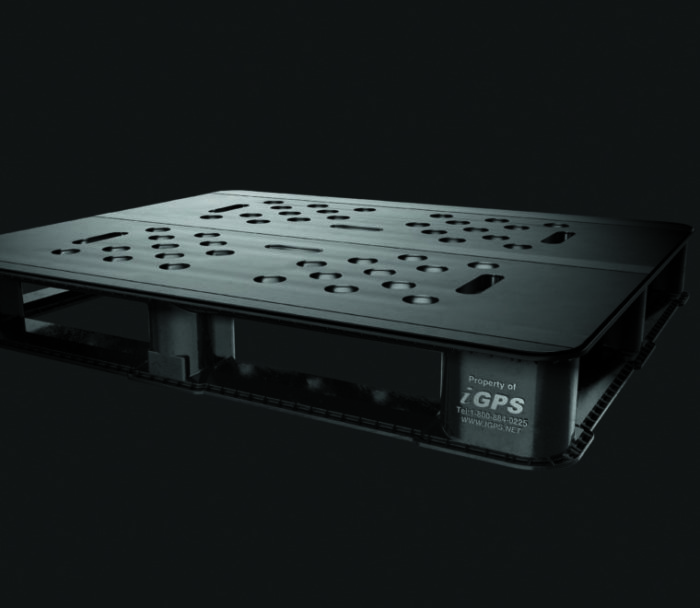

Plastic pallets maintain their strength while also being up to 35% lighter.

One of the best ways to assure efficiency is to standardize your pallets. We began this investigation with a question: “How strong are wood pallets?” That question led to the discovery that plastic pallets are not only stronger but have many advantages, including their ability to assist in automation, as well as their longevity. Plastic pallets have four times the lifespan of wood block pallets.

One of the best ways to assure efficiency is to standardize your pallets. We began this investigation with a question: “How strong are wood pallets?” That question led to the discovery that plastic pallets are not only stronger but have many advantages, including their ability to assist in automation, as well as their longevity. Plastic pallets have four times the lifespan of wood block pallets.

Additionally, plastic pallets maintain their strength while also being up to 35% lighter; plus, they are far more adaptable to the manual and automated rigors of the modern warehouse. As a result, plastic pallets can help you eliminate unnecessary supply chain questions and focus on increasing efficiency while lowering your total cost of business.

Innovate your supply chain and improve efficiency with the iGPS pallet pooling program. To learn more about how our pallets help lower your total cost of business, give our team a call at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page.