Pallet-level tagging via radio-frequency identification (RFID) sparks a tug-of-war within the supply chain. While retailers and distributors see it as a game-changer for visibility and efficiency, manufacturers remain apprehensive. However, market research from IDTechEx, a leader in the field for nearly two decades, suggests a bright future for RFID despite current challenges. Their report, “RFID Forecasts, Players, and Opportunities 2023-2033,” predicted a market value of $14 billion in 2023, an increase from $12.8 billion in 2022. This outlook encompasses all RFID components, including cards, fobs, tags, readers, and related software and services.

Where Barcode Case Tagging Falls Short

Manufacturers and retailers rely on stock-keeping units (SKU) barcodes to track inventories at the case and individual product levels. However, manual barcode scanning proves time-consuming and labor-intensive, leading to infrequent scans—typically at the point of departure from the manufacturer and upon arrival at the retailer- creating uncertainty for manufacturers. While barcodes have long tracked individual products, their speed, visibility, and data capture limitations hinder today’s fast-paced supply chains. Radio-frequency identification (RFID) on pallets offers game-changing solutions: faster scanning, deeper inventory insights, enhanced security, smarter logistics, and data-driven decisions. From preventing foodborne illness to optimizing transportation, RFID empowers businesses to revolutionize operations and embrace a more transparent, efficient future.

The Advantages and Disadvantages of Pallet Licensing

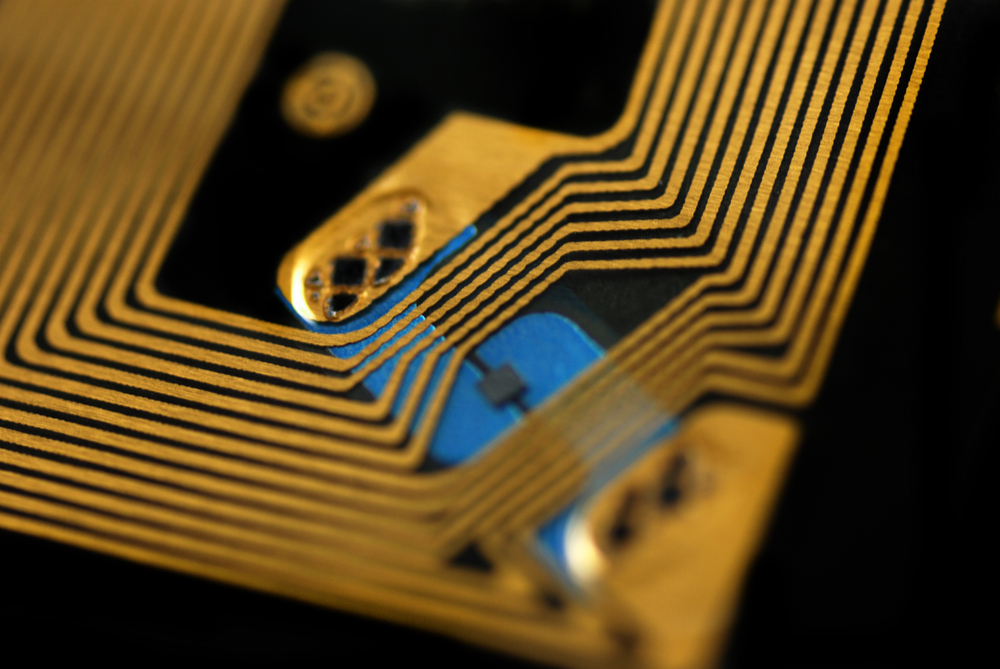

Pallet-level RFID offers instantaneous, real-time tracking — not just location but individual item details within each pallet. RFID tags also eliminate license woes like manual creation, lost tags, and limited data sharing while offering enhanced security.

A pallet license, often a sticker or paper, holds vital details about a pallet’s contents, including product type, quantities, and batch numbers. But this type of tracking and tagging also faces criticism for redundancy. Here are some potential drawbacks.

- Labor Intensiveness: Crafting a pallet license involves gathering, correlating, double-checking, and printing out relevant information, leading to increased preparation time before checking out a load. Additionally, checking in a load requires the manual scanning of each pallet.

- Limited Database Sharing: Without an extra effort to transmit recorded data to other stakeholders, the inventory check data remains localized within the warehouse, preventing other supply chain partners from accessing it for that specific product.

- Vulnerability to Loss: Pallet licenses, being physically attached to the pallet, are prone to loss, misplacement, or damage, resulting in unreadable information. In such instances, the recipient of the pallet must either manually inventory its contents or trust that it holds the intended products and has undergone proper handling.

Pallet licenses, despite widespread use, need more transparency and trackability. They need granular data capture, standardization, and real-time visibility, hindering accurate supply chain control. Enter RFID with individual item tracking, standardized protocols, and instant location updates that empower data-driven decisions. The $22.8 billion global market speaks volumes, as IDTechEx reported.

The Advantages of RFID Pallet Level Tagging

Compared to using traditional barcodes, RFID is more efficient for managing inventory. Instead of manually scanning each item, RFID allows quick and accurate tracking of pallets, cartons, and individual products. Recent research, like a 2023 Zebra Technologies study, highlights that six in 10 fulfillment center leaders plan to deploy RFID technology by 2028.

Utilizing RFID-enabled pallets with the right technology allows for effortless track and trace operations. Automatic scanning during entry and exit, along with real-time facility management system updates, ensures easy inventory database access. This transparency proves invaluable, especially in the food supply chain, where effective traceability not only improves business operations but can also prevent illness.

Individual item chips add up fast, but tracking pallets unlocks the supply chain at a fraction of the cost. Plus, reusable pallets like plastic ones mean each chip works overtime, maximizing value. From safer food to efficient pharmaceutical deliveries, pallet-level RFID is the budget-friendly key to a reliable, transparent supply chain.

Companies that want to streamline their supply chain operations choose iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable pallets have RFID chips embedded in them, improving tracking and traceability. For more information, contact us at 1-800-884-0225 email a specialist at switch@igps.net, or visit our contact page.