Warehouse automation involves using technology and equipment to streamline and optimize warehouse operations, including tasks like inventory management, picking, packing, and shipping. It reduces human labor, increases efficiency, and minimizes errors, often using systems like robots, conveyor belts, and software for data management.

Key Takeaways:

- Warehouse automation is rapidly transforming the logistics industry by increasing efficiency, accuracy, and speed.

- Advanced technologies such as robotics, AI, and data analytics are driving this transformation.

- Plastic pallet pooling is a crucial component of warehouse automation, enhancing sustainability and operational efficiency.

- The future of warehouse automation holds immense potential for further innovation and optimization, driven by continuous technological advancements.

The world of logistics is undergoing a reboot, driven by the relentless pursuit of efficiency, accuracy, and speed. Warehouse automation is at the heart of this revolution, a technology-driven approach redefining how goods are stored, moved, and managed. This transformation is fueled by innovations like robotics, artificial intelligence, and advanced data analytics, which collectively streamline operations and leave error-prone human habits in the dust. As customer expectations for speedy deliveries and intricate order fulfillment continue to soar, staying ahead of the competition can mean leveraging warehouse automation to streamline operations and maintain a competitive edge.

Warehouse Automation Key Technologies

Warehouse automation involves using technology to streamline warehouse operations, replacing manual labor with automated systems for inventory management, picking, packing, and shipping tasks. The global warehouse automation market is projected to grow from $19.27 billion in 2023 to $21.9 billion in 2024, representing a compound annual growth rate (CAGR) of 13.6 percent. The e-commerce boom is driving this growth, largely because online shoppers want their orders processed quickly and their favorite products consistently in stock.

Key technologies in warehouse automation include Automated Storage and Retrieval Systems (ASRS), Autonomous Mobile Robots (AMRs), and Automated Guided Vehicles (AGVs). ASRS systems are particularly valuable in high-density storage environments, where they can reduce labor costs and improve inventory accuracy by automatically placing and retrieving goods. AMRs, equipped with advanced sensors and AI, can navigate complex warehouse environments autonomously, offering flexibility in tasks such as picking and transporting goods. AGVs are also growing in use, expected to reach $3.3 billion by 2028 due to their efficiency in transporting materials within warehouses.

Other technologies, such as voice-directed picking systems and warehouse drones, are enhancing warehouse operations. Voice-directed systems guide workers through tasks using voice commands, speeding up processes and reducing errors. Drones are used for rapid inventory checks by scanning barcodes and RFID tags on products stored in high places.

The Role of Plastic Pallet Pooling in Warehouse Automation

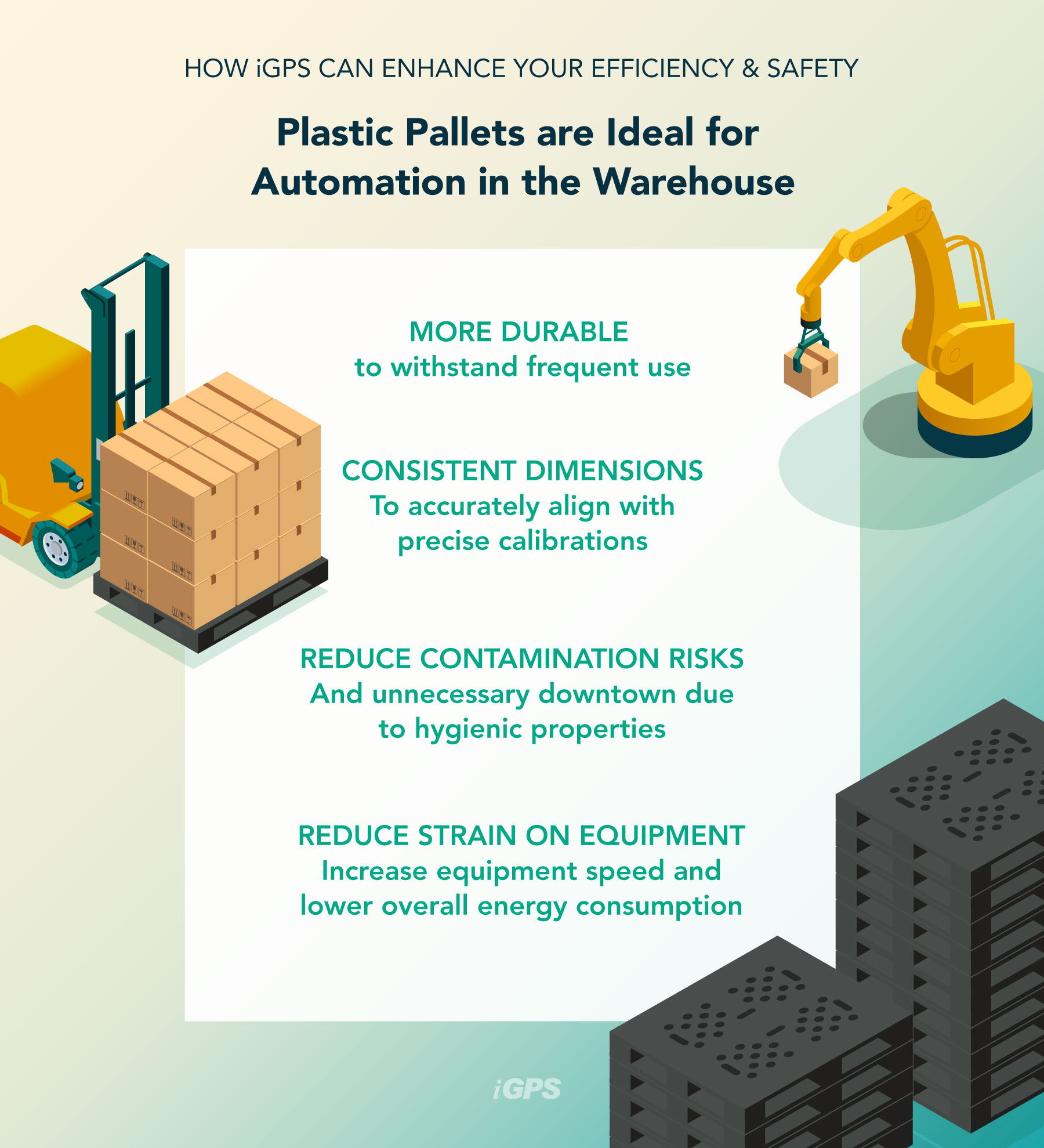

Beyond these advanced technologies, effective warehouse operations depend heavily on well-optimized material handling practices. That’s where plastic pallet pooling comes in; they can be indispensable for modern warehouse automation. Their durability, consistent dimensions, and hygienic properties make plastic pallets ideal for automated handling equipment. Unlike wooden pallets, plastic pallets are lighter, reducing energy consumption and system wear and tear. Additionally, their recyclability aligns with sustainability goals. By implementing a plastic pallet pooling system, warehouses can optimize automation, reduce downtime caused by damaged pallets, and improve overall operational efficiency while minimizing environmental impact. Ultimately, this strategic choice ensures a seamless integration of technology and sustainability in warehouse management.

The Future of Warehouse Automation

With this strong foundation in place, the industry is ready to embrace even more groundbreaking advancements. The future of warehouse automation looks promising, with continuous technological advancements driving further efficiency gains. Beyond operational efficiency, the ROI of warehouse automation may continue to expand as technology evolves. Emerging areas like predictive analytics, powered by AI, will optimize inventory management, reduce stockouts, and improve order fulfillment accuracy. In fact, the global predictive analytics market is poised for significant growth, expanding from $1.95 billion in 2022 to a projected $2.25 billion by 2028, according to Market Research Guru. This translates to significant cost savings and revenue growth. In the end, these advancements may redefine the logistics and commerce landscape, enabling businesses to thrive in the dynamic marketplace.

What are the primary benefits of implementing warehouse automation systems?

Warehouse automation can offer many benefits, including increased efficiency, improved accuracy, reduced labor costs, enhanced inventory management, and faster order fulfillment. By automating repetitive tasks, businesses can allocate human resources to more strategic and value-added activities.

How does warehouse automation contribute to improving supply chain efficiency and resilience?

Warehouse automation can streamline operations, reduce lead times, and minimize errors, leading to a more efficient supply chain. Additionally, it can help businesses adapt to fluctuations in demand and disruptions by providing greater flexibility and responsiveness.

What are the key challenges businesses face when adopting warehouse automation technologies?

Implementing warehouse automation can involve significant upfront costs, requiring careful ROI analysis. Additionally, businesses may need to invest in employee training to operate new systems and adapt to changes in workflows. Integrating automation with existing systems can also be complex.

How can small and medium-sized enterprises (SMEs) benefit from warehouse automation?

SMEs can benefit from warehouse automation by adopting scalable solutions tailored to their specific needs. Cloud-based systems and modular automation technologies can be more accessible and affordable for smaller businesses, enabling them to improve efficiency and compete with larger companies.

Why are plastic pallets considered ideal for automated handling equipment in warehouses?

Plastic pallets are preferred in automated warehouse environments because of their durability, consistent dimensions, and hygienic properties. Unlike wooden pallets, plastic pallets are less likely to break, reducing downtime caused by damaged pallets. They are also lighter, which decreases energy consumption and wear and tear on automated systems. Their consistent size and shape are crucial for compatibility with automated handling equipment, ensuring smooth operations.

What is the return on investment (ROI) typically associated with warehouse automation projects?

The ROI of warehouse automation varies depending on factors such as the scale of implementation, chosen technologies, and operational efficiency improvements. While initial investments can be substantial, long-term benefits, including increased productivity, reduced labor costs, and inventory optimization, can generate significant returns.

Manufacturers looking to automate their warehouses can enhance their logistics operations by opting for iGPS plastic pallets. IGPS pallets’ uniform size, weight, and construction enable them to flow seamlessly through automated equipment without snags. For more information, contact us at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page.