ARTICLE UPDATED ON AUGUST 24, 2023

Ensuring the safe movement of products through the supply chain heavily relies on having the appropriate shipping pallets. The difference between smoothly transferring goods from the truck to their next destination, and encountering inventory mishaps due to pallet failure, lies in the reliability of the chosen pallets.

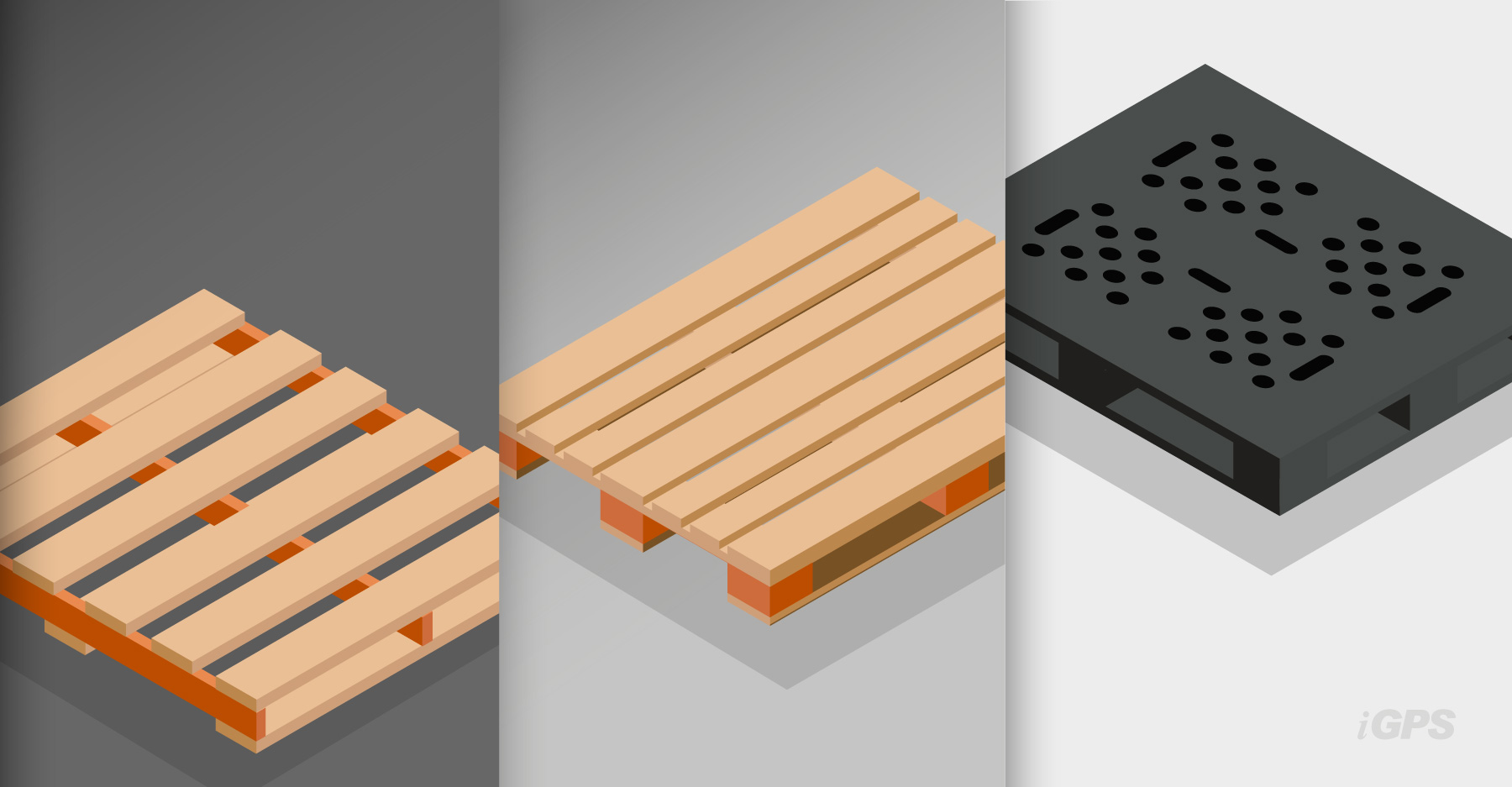

The United States accounts for approximately two billion pallets in use, and of that, 90 percent are wooden pallets. For most logistics managers, the decision-making process often boils down to a comparison between block pallets and stringer pallets, as these are the most commonly encountered styles. Initially, the comparison between the two seems relatively simple, but as you delve deeper into understanding these pallets, making the right choice can become more challenging. While both types have their advantages, they also share fundamental flaws. That’s why some choose to also explore alternatives to the traditional options of wood block and stringer pallets.

The Difference Between Block Pallets and Stringer Pallets

The biggest difference between block and stringer pallets is the support used between the top and bottom decks of the pallet itself. Stringer pallets are held together by three two-by-four boards, one running along each side of the pallet and one through the middle. These are the “stringers” that give the pallet its name, and they are usually notched to allow forklift access from all four directions. Block pallets, on the other hand, are held together by nine four-by-four-inch wood blocks, sometimes with additional boards around the perimeter that reinforce the top and bottom decks.

|

|

|

|

| Wood Stringer Pallets | Wood Block Pallets | Plastic Pallets | |

| Pallet Weight | 33 to 48 lbs. | 75 to 80 lbs. | ~50 lbs. |

| Static Load | 2,500 lbs. | 5,500 lbs. | 30,000 lbs. |

| Dynamic Load | 2,200 – 2,500 lbs. | 4,600 lbs. | 5,000 lbs. |

| Edge Rackable Load | 2,500 lbs. | 2,800 lbs. | 2,800 lbs. |

| Lifetime Trips | 1 – 3 trips | ~ 20 trips | ~ 100 trips |

| Materials | Often softwood | Often hardwood | HDPE Plastic |

| Forklift Entry | 2- or partial 4-way entry | 4-way entry | 4-way entry |

The stringer pallet has long been among the most commonly used pallets throughout the supply chain. And odds are that this is the design most people think of when they hear the word pallet. However, they are not very durable and are designed to make only a few trips through the supply chain before being discarded. Stringer pallets tend to pile up behind shopping centers, grocery stores, and warehouses because they are not durable enough to travel repeatedly through the supply chain, requiring companies to constantly replace old stringer pallets with new ones to keep their supply chains running.

Block pallets, meanwhile, are designed for greater durability, and for that reason, more wood goes into building them. More wood requires more nails, and those nails are significantly heftier than the ones found on stringer pallets. The result is a sturdier, fully four-way pallet that can make far more trips through the supply chain than the stringer pallet. However, the strength of the block pallet means a significant increase in weight and in the fuel needed to transport them.

When to Use Block Pallets vs. Stringer Pallets

Although stringer pallets are less durable than block pallets, their historically low price has made them enticing for many supply chain managers, and in some circumstances, they may be a reasonable choice. If you’re shipping a partial unit load to a part of the supply chain in which bringing the pallets back is impractical, a lightweight and inexpensive stringer pallet may be the best platform to use.

Although stringer pallets are less durable than block pallets, their historically low price has made them enticing for many supply chain managers, and in some circumstances, they may be a reasonable choice. If you’re shipping a partial unit load to a part of the supply chain in which bringing the pallets back is impractical, a lightweight and inexpensive stringer pallet may be the best platform to use.

For most situations, however, block pallets are the smarter choice:

- Heavy Goods Shipping: Products such as bottled water, beverages, and canned goods are heavy, especially when loaded in bulk onto a pallet. A block pallet is a better choice than a stringer pallet for goods like these, as the more robust construction of this pallet handles the weight and movement more easily than a stringer pallet and with less risk of failure.

- Multi-Step Supply Chain: A block pallet is more likely to hold together through repeated handling than a stringer pallet – making block pallets a better choice for complicated supply chains that see loads of product changing hands multiple times.

- Reducing Wasted Materials: Block pallets can make significantly more trips through the supply chain than the stringer pallet. If a logistics manager is in the position to set up a reverse supply chain, which will allow for pallets to make their way back to the production site once they’ve completed a trip through the supply chain, then using block pallets can reduce the need to constantly replenish a supply of pallets

- Reducing Rejected Loads: Retailers are entitled to reject loads that come in on pallets they find unacceptable, and the cost of these rejected loads — or the cost to transfer a load to an acceptable pallet — adds up quickly. Stringer pallets are more likely to be rejected than block pallets. In fact, some retailers will not accept stringer pallets at all, requiring their suppliers to use wood block or alternative material pallets.

Despite the superiority of block over stringer pallets, when made of wood, both types of platforms suffer from inefficiencies:

- The presence of wood splinters and nail debris can damage products, packaging, and machinery, as well as injure workers.

- The platform itself can become damaged over time, resulting in cracked boards, splinters, and even the possibility of total pallet failure.

- Wood is difficult or impossible to sanitize, as it absorbs moisture and chemicals and may spread contamination.

- The cost benefits of wood have diminished as lumber prices have risen and wood pallet manufacturers have moved away from basing their prices on wood indexes.

For these reasons, many supply chains may be better served by a third pallet option: the plastic pallet.

Plastic pallets combine the advantages of stringer pallets with those of block pallets and add many of their own advantages. Plastic pallets have a durability that vastly exceeds even that of wood block pallets, and around fifty pounds, their weight is comparable to that of stringer pallets. Their resilience and high quality allow plastic pallets to make 80 to 100 trips through the supply chain, significantly more than the number of trips that wood block pallets can make. The light weight and reusability factor of plastic pallets enables them to reduce the strain on employees and equipment, decrease transportation fuel costs, and eliminate the need for a constant supply of new pallets. Supply chains can enjoy these advantages with very little additional effort by partnering with a plastic pallet pooling system, which manages the transportation and supply of pallets and makes them available whenever and wherever they are needed.

Choosing a pallet doesn’t have to be just about block pallets vs. stringer pallets anymore; pooled plastic pallets offer a sustainable alternative that is superior to any wood pallet.

Companies looking to move away from wood-based block and stringer pallets use iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable plastic pallets incorporate RFID technology, making them traceable throughout a supply chain. For more information, contact us at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page