ARTICLE UPDATED ON SEPTEMBER 29, 2023

Static Load vs. Dynamic Load: Demystifying Pallet Load Ratings

Understanding the distinction between a dynamic load and a static load within a warehouse is essential for ensuring the safety of employees and products. Simply put, a static load refers to stationary loads, while dynamic loads involve movement. Specifically, within the supply chain context, a static load pertains to a pallet loaded and positioned on the floor, whereas a dynamic load involves a pallet in motion, being transported by equipment like forklifts or pallet jacks.

Given that a pallet will typically experience both dynamic and static conditions throughout its journey, it becomes crucial to have knowledge about the load capacities associated with each type. Different pallet materials and designs come with varying ratings for dynamic and static loads. Familiarizing oneself with these variances enables informed decision-making when selecting the most suitable pallet for meeting the unique requirements of the supply chain.

Static Load Vs. Dynamic Load: The Basics

Each shipping pallet is required to have two distinct maximum weight ratings: a static load rating and a dynamic rating. Neglecting these load ratings on pallets poses significant risks. A failed pallet has the potential to pose a hazardous situation in a warehouse, endangering the lives of employees. This emphasizes the crucial importance of comprehending the disparity between these two ratings in order to ascertain the maximum load capacity per pallet.

Static Load Rating

The static load rating is the load rating for a pallet when it is not moving. An example would be pallets holding stock in storage on the warehouse floor. This number tells warehouse personnel how much weight a pallet can handle per stack, as the bottom pallet will bear the brunt of the weight in a stack of multiple loaded pallets. Static load capacity is typically higher than dynamic, so products may need to be offloaded from the pallet to get it under the weight requirement for movement.

Dynamic Load Rating

The dynamic load rating gives the maximum weight capacity for a pallet being moved. Typically, this means the pallet is being lifted and carried using a forklift, pallet jack, or stacker crane. Load distribution is of vital importance, as unevenly distributed weight can cause the pallet to tip or flip during movement.

Edge-Rackable Load Rating

Edge-rackable load capacity refers to how much weight a pallet can support while stored on a pallet racking system. Since warehouse racking usually involves racks that support pallets by only two edges, a pallet’s racking capacity is generally lower than either its static or dynamic capacity. Racking capacity is also dependent on the strength of the warehouse racking itself, which is often the limiting factor.

In most cases, the static weight capacity of a pallet will far exceed its dynamic capacity or edge-rackable capacity. This is because, in a static load, the force of the load on the platform remains constant. In a dynamic load, it might change abruptly during acceleration or deceleration, or weight may shift from one area to another. Pallet jacks and forklifts also place concentrated pressure on pallets, rather than supporting the loaded pallet’s weight evenly. As a result, a pallet’s dynamic capacity usually only represents a fraction of the static rating.

Choosing Pallets That Support Loads Under Any Condition

A pallet’s load capacity comes from its underlying material and basic design. Since many of these designs are standardized, their dynamic and static load capacities are relatively consistent and predictable.

A pallet’s load capacity comes from its underlying material and basic design. Since many of these designs are standardized, their dynamic and static load capacities are relatively consistent and predictable.

| Type of Pallet | Static Rating | Dynamic Rating |

|---|---|---|

| Wood stringer: These are typically the cheapest pallets available for commercial use. These pallets use notched boards or “stringers” to support top and bottom deck boards. | 2,500 pounds | 2,500 pounds |

| Wood block: Block pallets are more durable than stringer pallets as they’re constructed using more substantial boards and wood blocks. This increased stability also boosts their weight capacity. | 5,500 pounds | 4,600 pounds |

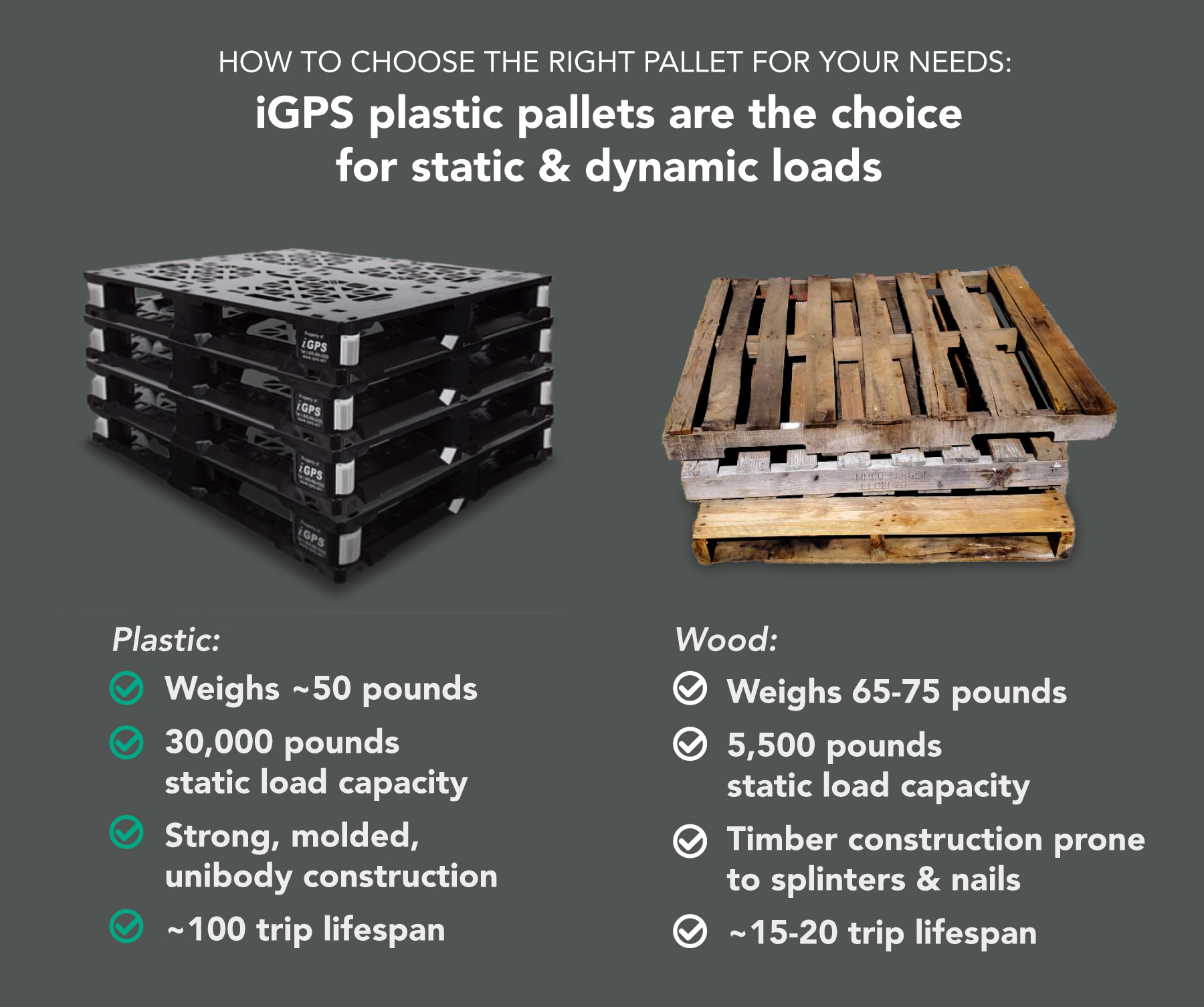

| Plastic: A high-quality plastic pallet usually weighs under 50 pounds. Since it’s molded, rather than fastened together, there are no screws or other hardware, and each pallet is uniform with every other pallet. | 30,000 pounds | 5,000 pounds |

Many factors can impact a pallet’s dynamic and static load capacities. This includes the age of the pallet, type of wood used (in the case of wood pallets), and whether they’ve had any damage or repairs. Ideally, it’s best to round the weight up when loading pallets to limit the risk of overloading them.

Comparing the static load vs. dynamic load of different pallet materials and types, it’s clear that high-quality plastic pallets are the strongest. Their high static load capacities make plastic pallets excellent choices for storing products in the warehouse. As plastic pallets also typically have a dynamic capacity that exceeds that of their wood counterparts, loaded plastic pallets can be moved without first taking products off the pallet. The greater strength and durability of plastic pallets ultimately reduces the likelihood of product damage as a result of pallet failure as well, saving businesses money and time over the long-term.

Choosing between static loading and dynamic loading depends on the specific needs of a enterprises logistics operations. If the priority is stability, durability, and long-term storage, static load is the ideal choice. On the other hand, if the focus is on continuous movement, transportation efficiency, and versatility, a dynamic load offers a more suitable solution. Ultimately, a well-informed decision regarding pallet selection can lead to improved efficiency, reduced costs, and enhanced customer satisfaction in your supply chain.

Companies comparing static vs dynamic load use iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable plastic pallets incorporate RFID technology, making them traceable throughout a supply chain. For more information, contact us at 1-800-884-0225, email a specialist at switch@igps.net, or visit our contact page