ARTICLE UPDATED ON FEBRUARY 2, 2023

Constructed to comply with international export standards, heat-treated pallets are wood pallets that are treated at high temperatures in order to lower moisture content. This makes them less prone to problems such as wood rot or insect infestation.

These pallets are costlier than traditional wood pallets; the additional time it takes to produce these pallets means they can be difficult to buy in sufficient quantity, and manufacturers can often increase prices depending on demand. This can be challenging for businesses attempting to secure a fleet of certified heat-treated pallets. Companies that solely ship domestically often cannot justify the expense. For those looking for a pallet at a lower cost that can ship internationally, many businesses turn to plastic pallets. Plastic pallets come with the advantages of heat-treated pallets and, additionally, are exempt from the export requirements for wood pallets.

Three Benefits of Heat-Treated Pallets

There are many ways to complete heat treatment for wood pallets, but each method typically involves three stages. First, the wood must be thoroughly debarked. Then, it is placed in an enclosed space and heated to a temperature of at least 132.8 degrees Fahrenheit for a minimum of 30 minutes. Once this is complete, the wood is marked with a stamp that shows the treatment was completed in compliance with internationally required standards. Pallets treated with this method are superior to standard wood pallets for several reasons:

1. Export compliance:

The International Phytosanitary Standard for Wood Packaging, otherwise known as ISPM-15, requires that wood packaging be heat-treated before export to foreign countries in order to reduce the risk of pest infestation. Since heat-treated pallets are clear of potential fungi, diseases, and insects, they can be used for international trade. Standard pallets cannot be used for such trade because of the risk of insects and diseases spreading to areas where they are not native which could prove disastrous to local trees. For international commerce or even commerce across state lines, heat treated pallets are a must.

2. Reduced weight:

The weight of an average wood pallet is anywhere from 30 to 80 pounds, with more durable pallets weighing more as they use more wood. Heat treatment takes moisture out of new wood, which lightens the pallet. While heat treatment doesn’t cause a dramatic loss in weight, when many pallets are being transported at once, the weight savings can add up, resulting in lower fuel usage for loads that cube out and more product in each load for those that weigh out.

3. Lower risk of mold and bacterial growth:

Bacteria and mold thrive in moist environments, and wood is the perfect breeding ground due to its porous nature. This leads to unsanitary conditions that can jeopardize products and create safety hazards. Heat-treated pallets can lower the risk of product contamination and load rejection.

Plastic Pallets As an Alternative to Heat-Treated Platforms

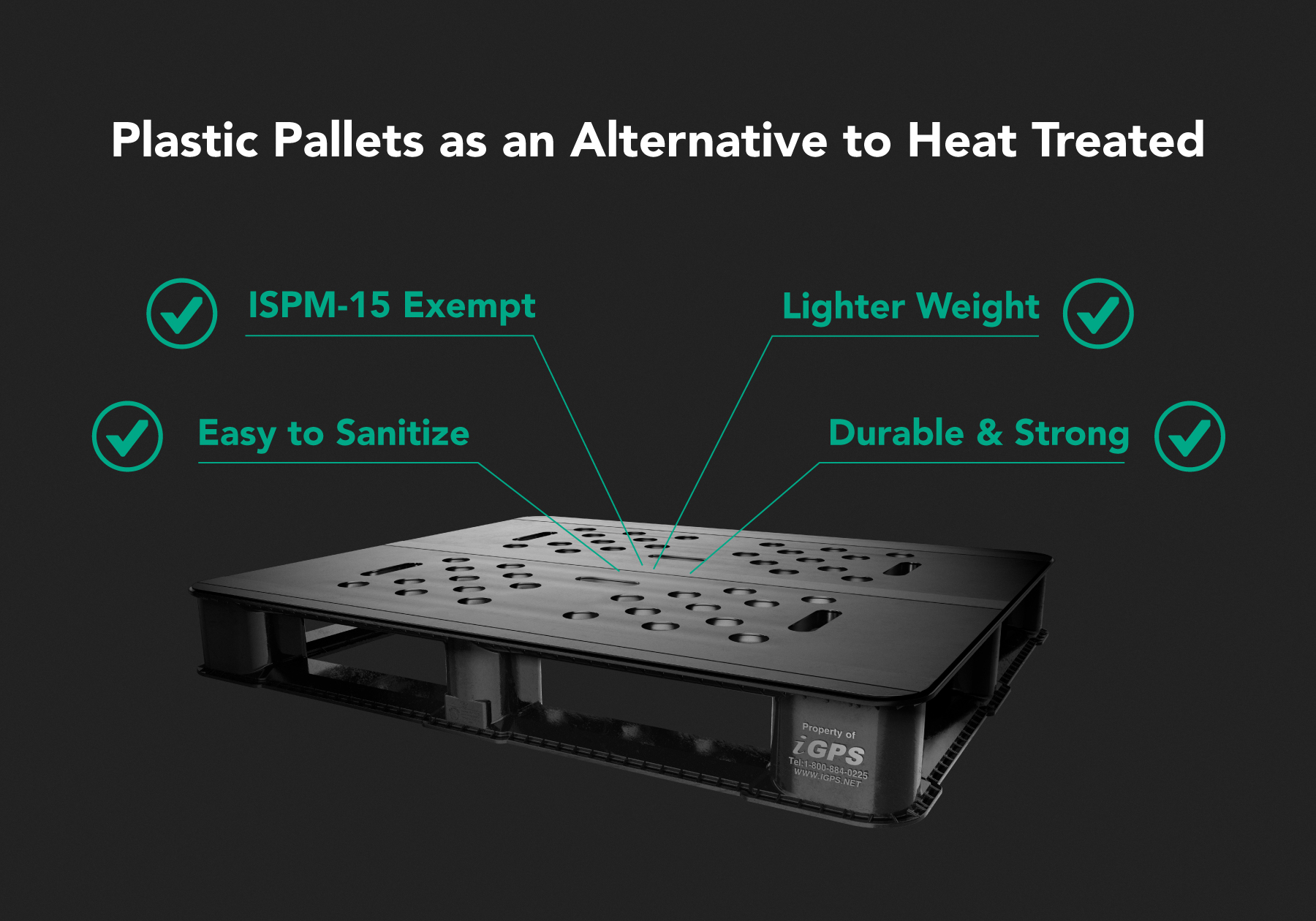

Heat-treated pallets present higher costs and sourcing difficulties when compared to plastic pallets. The latter are a sustainable alternative to their heat-treated wood counterparts, and their benefits make their cost easy to justify. Plastic pallets provide:

1. Exemption from ISPM-15: Since they have a very low risk of infestation, plastic pallets are exempt from ISPM-15. Plastic is a non-porous material, so it does not attract insects or mold. The penalties for ISMP-15 violations are high and even the most careful companies can face them through a simple mistake or damage to the required ISMP stamp. The best way to avoid violations for failing to meet ISPM-15 wood pallet requirements is to use plastic pallets.

2. Consistently low weight: The average multi-use plastic pallet weighs 50 pounds, and they do not absorb any moisture. The removal of extra weight can maximize profits by reducing fuel mileage in the supply chain. Reducing energy use and carbon dioxide emissions is good for business and beneficial for the environment.

3. Bacteria and mold resistance and easy sanitation: Since moisture isn’t absorbed by plastic, it’s possible to thoroughly clean and even sanitize a plastic pallet, something that is not possible with wood platforms. Plastic pallets are more hygienic than wood, which allows shippers to reduce the risk of contamination and thus, rejected loads.

4. Lower product damage: High-quality plastic pallets are far more durable than wood pallets. They are less likely to splinter and damage product packaging and automated equipment during handling.

All the benefits of heat-treated pallets can be found in plastic pallets, along with added perks. Reusable plastic pallets can reduce the total cost of business (TCOB) for supply chain stakeholders without the need for additional treatment or specialized stamps. Plastic pallets are even more cost-effective when rented from a pallet pooling service, such as iGPS. Plastic pallet pooling eliminates the large upfront cost of purchasing a fleet, lowers costs associated with platform maintenance, and removes the hassle of sourcing large quantities of heat-treated pallets. Plastic pallet pooling makes it simple for both global and domestic companies to streamline shipping and reduce transportation costs.

Companies that want the benefits of heat-treated pallets without the expense and risks use plastic pallets from iGPS, which are lightweight, recyclable, and help streamline your supply chain. For more information, contact us at 1-866-557-0047, email switch@igps.net, or visit our contact page. We also invite you to follow us on LinkedIn.

Image 2: Wikimedia Commons, self-made by the uploader – Own work, CC BY-SA 2.5 ca