ARTICLE UPDATED ON JUNE 2, 2023

Standard wood pallets can be manufactured by both large and small companies, out of various types of wood. Though the design is similar, the variables involved often mean that they will have different weights. Wood-block pallets can weigh anywhere from 65 to 75 pounds depending on several factors, including:

- Material

- Age

- Manufacturer

- Porosity

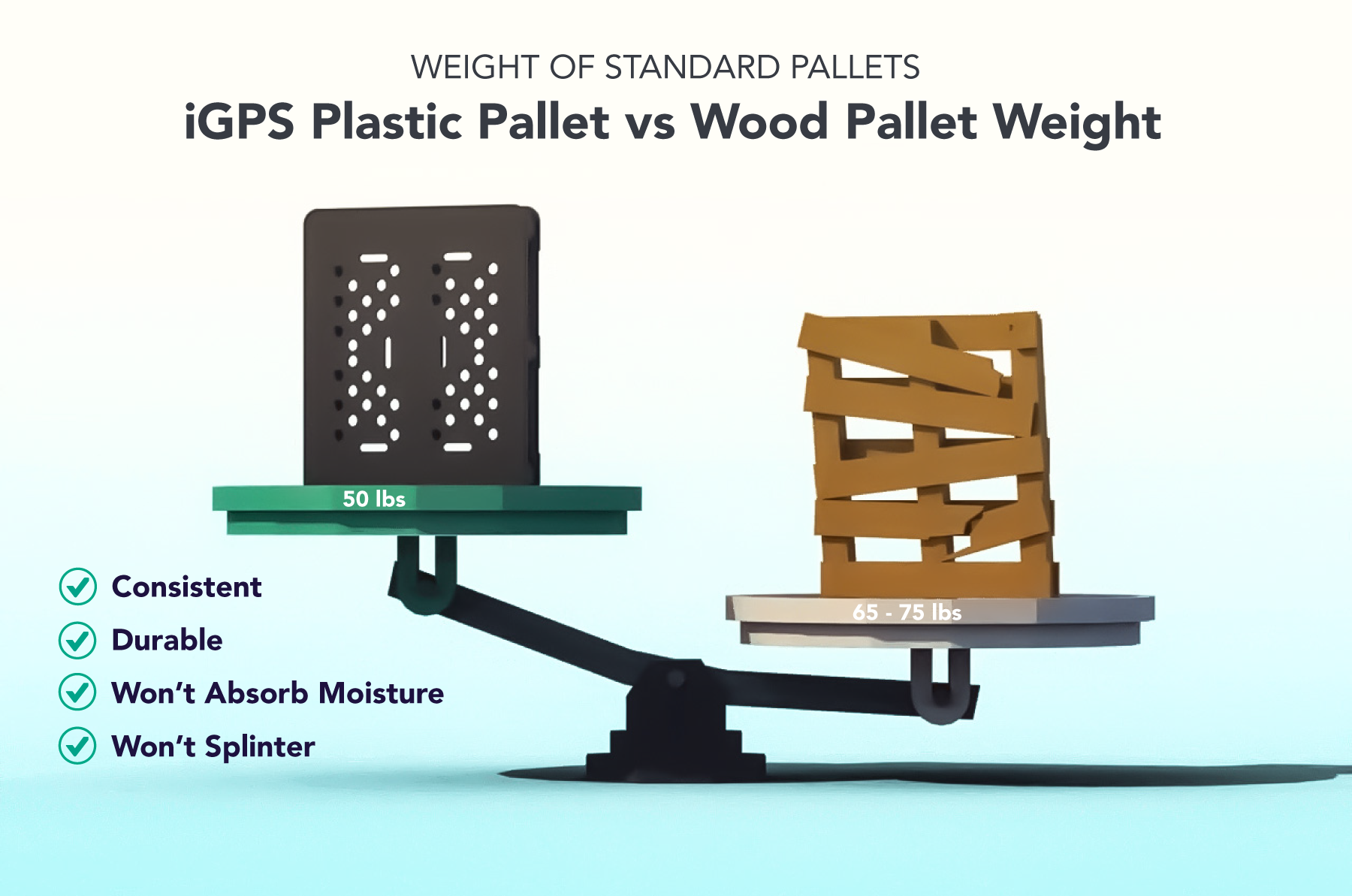

Choosing a pallet is an important decision for any supply chain stakeholder. A heavier pallet may hold more product, but the trade-off is higher transportation costs. Most lightweight pallets are fuel-efficient and more convenient to handle than heavy pallets, but often lack capacity and durability. On the factory floor, lightweight pallets continue to offer cost savings by reducing wear on machinery and injuries to employees. Corrugated cardboard pallets, for example, offer much lower weights but typically aren’t appropriate for continuous use. Meanwhile, plastic pallets weigh around 50 pounds and offer the strength of a much sturdier pallet without the added weight.

Types of pallets and their weights

- Standard “stringer” pallets: A standard “stringer” pallet measures 48 by 40 inches and weighs around 40 pounds. These pallets are typically made of softwood and have a maximum dynamic load capacity of about 2000 pounds. Their simple design makes them lower in weight, but also prone to wear and tear. In many cases, retailers reject loads shipped on stringer pallets due to issues caused by breakage and splintering, such as product damage. These pallets are not appropriate for heavy industrial use. The same goes for cardboard pallets, which generally weigh no more than 20 pounds but are even more prone to damage.

- Wood block pallets: An alternative to stringer pallets is the wood block pallet, a sturdier hardwood pallet with greater longevity than its counterpart. Wood block pallets can weigh between 65 to 75 pounds. While they are often used for high-volume or heavy products, they still have issues with splintering and breakage and their significant weight can impact fuel efficiency and wear and tear on automated storage systems and other machinery.

- Heavy duty plastic pallets: Plastic pallets such as those made by iGPS are the best option to support to heavier loads while minimizing platform weight. High-quality rackable plastic pallets weigh around 50 pounds but can hold even heavier loads than their wood block pallet counterparts. They’re more durable than wood pallets and won’t absorb damaging moisture or splinter during transport. Another, somewhat underrated, benefit of plastic pallets is that, unlike wood pallets, their low weight stays consistent from platform to platform and from use to use.

Why does wood pallet weight change over time?

One major problem with wood pallet weight is consistency. Two different pallets may have very different weights due to factors such as the manufacturer’s design and wood choice. As a result, manufacturers and warehouses are often forced to deal with many pallet weights at the same time.

Moisture also changes the weight of wood pallets. As wood is porous, moisture can soak into the pallet, changing its weight. The weight of a standard pallet may even differ throughout the supply chain as goods travel to drier or more humid environments.

Eliminating these fluctuations requires looking to a non-porous alternative such as plastic. Plastic pallets have a consistent weight across the manufacturer’s entire line, and that weight stays the same for the pallet’s entire lifespan, from manufacturing all the way through to its last use.

Why Consistent Platform Weight Matters

Being able to predict the weight of a standard pallet is crucial to keeping the supply chain running smoothly and efficiently, since pallet weight impacts everything from budgeting to personnel allocation. There are several specific reasons why having a consistent pallet weight is especially important:

- OSHA restrictions: The Occupational Safety and Health Administration (OSHA) clearly recommends that a single employee should not lift anything over 50 pounds. As wood pallets are so close to this threshold, most companies will default to a two-person lift protocol on every pallet to keep employees safe and to stay OSHA compliant. Still, employees may choose to lift these pallets by themselves, which can cause injuries and potentially open the company up to fines and penalties. A plastic pallet with a predictable pallet weight of 50 pounds, eliminates this problem by making it possible for employees to lift the pallet on their own without violating protocol. In addition, plastic pallets feature ergonomically friendly grab holes which make them easier to carry and manipulate.

- Automation: Pallet weight variance is a significant problem in any automated supply chain process as machines must be calibrated to manage a specific weight. When wood pallets in the same shipment have different weights, the inconsistencies can wreak havoc on automated systems.

- Estimating transport weight capacity: Companies often overestimate their shipment weight to account for fluctuations in pallet weight. However, using a pallet with a consistent weight lets companies transport more, as they can be confident the estimated weight is accurate.

- Estimating fuel and transport costs: The Total Cost of Business (TCOB) is heavily impacted when key decision makers underestimate the impact of pallet weight or are forced to overestimate it due to wood pallet weight fluctuations. With a more consistent pallet weight, stakeholders can make more accurate determinations when calculating fuel and transportation costs.

Weight fluctuation makes the exact weight of a wood pallet nearly impossible to determine, and businesses will end up paying for them in the long run. Strong plastic pallets are sufficiently lightweight and durable to create consistency for companies trying to accurately gauge their shipping costs while maximizing the number of goods delivered. Any enterprise concerned about how wood pallets are raising their Total Cost of Business should consider switching to a reliable plastic platform.

Companies that want reliable and consistent pallet weight and performance use plastic pallets from iGPS, which are durable, recyclable, and help streamline your supply chain. For more information, contact us at 1-800-884-0225, email switch@igps.net, or visit our contact page. We also invite you to follow us on LinkedIn.