-

Will There Be a Truck Driver Shortage in 2019?

Transportation costs are rising–and have been for some time–across all industries. The economy is growing, and as business picks up, more freight has to be carried on the same number of trailers and trains. It’s a cycle that the country has seen many times before. In recent years, however, other factors have also come into…

-

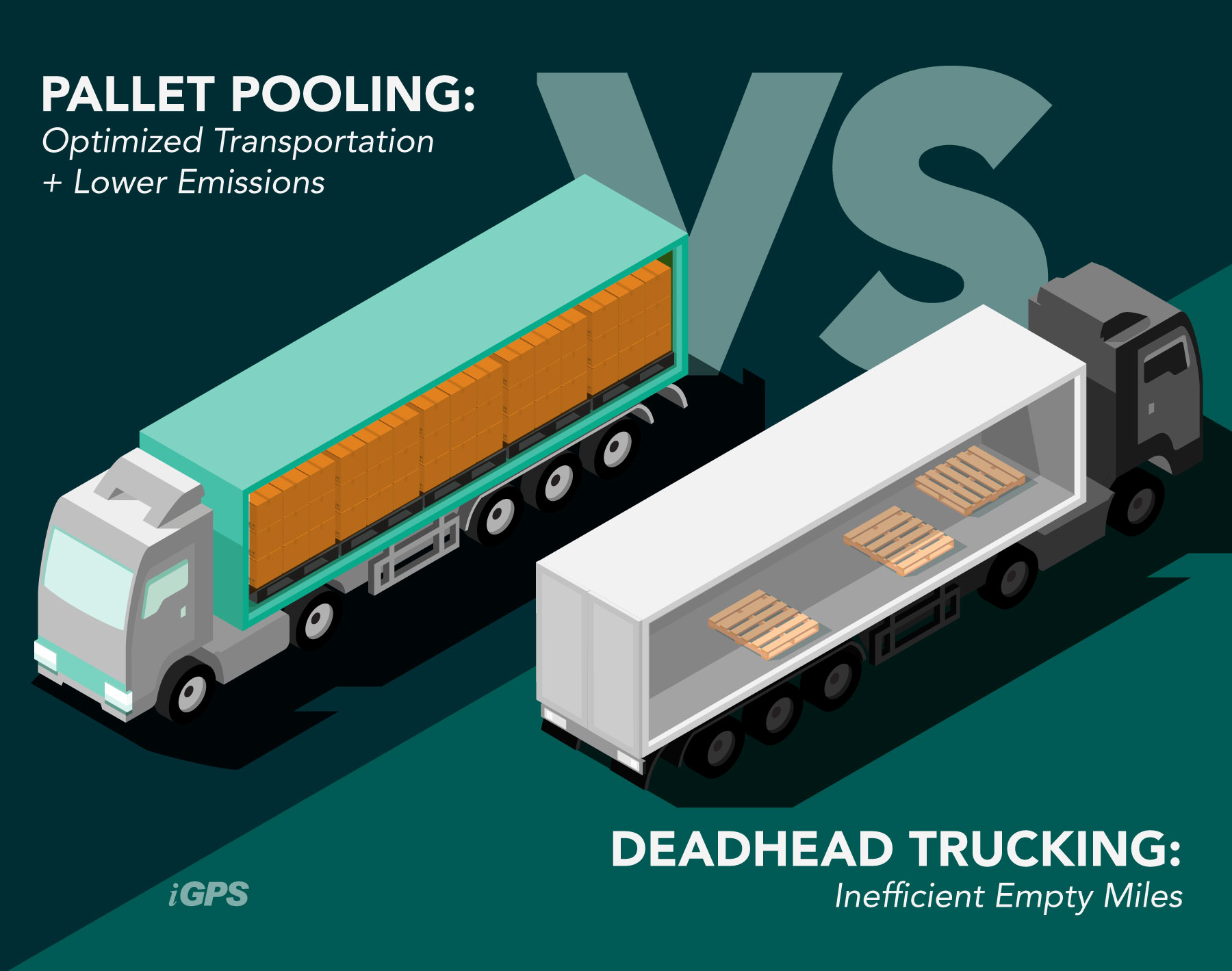

Deadhead Trucking: Avoiding Empty Miles

Key Takeaways: Deadhead Trucking: Avoiding Empty Miles In the world of logistics, empty miles are a constant headache. We’re talking about deadhead trucking, those big rigs cruising down the highway with no cargo. This translates to lost revenue – the truck isn’t generating income while it burns fuel. Deadhead trucking is the epitome of supply…

-

How to Use Warehouse Picking Best Practices

Warehouse picking is the simple act of pulling product loads out of inventory. However, picking the right loads and doing so speedily without wasting time double-checking manifests can be complicated. The difficulty of the task scales up with the size of the warehouse, the density of the product it contains, and the number of different…

-

Finding Cost-Effective Pallet Management Strategies

If you’ve spent any amount of time around a grocery store or other packaged goods retailer, you know that abandoned pallets are a common sight. Orphaned pallets can often be found propped against the back walls of retail stores where drivers abandoned them after delivery. To dispose of the pallets, the retailer will generally end…

-

How to Sanitize Plastic Pallets: Keeping Your Supply Chain Hygienic

Across this great land, piled behind millions of grocery and department stores, are millions of reusable wood block pallets. At many of those stores, teenagers working their first jobs have been ordered to add another pallet to the stack out back, and are thinking, “Ew, I have to touch that?” Wood pallets easily collect grime…

-

Dealing with and Preventing Rejected Loads

Truckers in 2024 juggle tight deadlines and sustainability concerns on every haul. Imagine their frustration when arriving after a long trip only to face a rejected load. These aren’t just headaches; they’re delays, extra costs, and unnecessary miles harming the environment. Even though rejected loads usually go back to the seller, convincing some sellers of…

-

What Is Palletizing?

ARTICLE UPDATED ON MAY 22, 2023 What Is Palletizing? Pallets are a crucial element of the supply chain. Inherently simple in structure, pallets are used to store, protect, and transport materials. Palletization is a term used to describe the process of placing materials and packages onto pallets. Though it may sound simple, palletizing for high-volume…

-

The Advantages and Disadvantages of an ASRS

Key Takeaways: The Advantages and Disadvantages of an ASRSHeavy equipment operators often rely heavily on their skills, sometimes disregarding managerial guidelines. This can lead to incidents where warehouse supervisors and logistics coordinators hear loud crashes, only to find products strewn across the floor and a forklift operator struggling to explain why they ignored safety instructions.…

-

The Warehouse of the Future: Planning for Intelligent Transformation

Twenty years ago, a warehouse worker would wake up, fill a thermos with coffee, and hop into his car to drive to work. He might run into traffic on the way there and flip through radio stations looking for a good song. When he arrived at the warehouse, he would get the day’s paperwork from…

-

Warehouse Racking Safety Guidelines: Satisfying OSHA

ARTICLE UPDATED ON JUNE 21, 2023 Warehouse Racking Safety Guidelines: Satisfying OSHA The Occupational Safety and Health Administration (OSHA) has an important job — keeping workplaces and workers safe. However, its rules are often nuanced, complex, and hard to follow, making it easy for employers to accidentally violate an obscure rule. Violations usually carry steep…

-

Following Lean Warehousing Principles for Improved Efficiency

ARTICLE UPDATED ON JUNE 22, 2023 Following Lean Warehousing Principles for Improved Efficiency A top goal for warehouse managers is to run an effective operation in which productivity is high and goods flow efficiently throughout the supply chain. However, as markets continue to shift, demand skyrockets, and the supply chain evolves, it can be difficult…

-

How to Keep a Warehouse Clean

One of the constants of working in a warehouse is grit, grime, and miscellaneous trash that no one really knows the source of. Keeping a warehouse clean is an ongoing struggle, and one that is becoming more and more important. A dirty or cluttered warehouse is not only an eyesore and a safety hazard, but…