ARTICLE UPDATED ON MARCH 15, 2024

In any warehouse or logistics facility, a primary concern is to guarantee the safe storage and intact delivery of products to end-users. Current Good Manufacturing Practice Standards (CGMPS) are an evolving set of standards aimed at ensuring the quality and integrity of products passing through such warehouses. In most industries, these practices are typically standardized through mutual agreements among companies operating within those sectors. However, in the case of food and pharmaceutical warehouses and fulfillment centers, CGMPS fall under the jurisdiction of the Food and Drug Administration (FDA) and carry the full force of legal authority.

The FDA’s warehouse requirements for pharmaceuticals encompass a wide spectrum of products, ranging from over-the-counter medications to biological substances such as blood or plasma used in pharmaceutical production. These requirements do not provide extensive design specifications; instead, their primary focus lies in maintaining precise temperature controls to preserve the effectiveness of medicines and prevent spoilage. Furthermore, they establish protocols to safeguard pharmaceuticals against contamination from biological, chemical, or physical contaminants.

FDA Pharmaceutical Warehouse CGMPS

The FDA has an extensive list of responsibilities that covers not only every existing pharmaceuticals, but the development and testing of new ones. With such a large writ of responsibility, it would be impossible for the FDA to codify in-depth regulations for the proper handling and storage of every distinct product moving through the supply chain. Different types of pharmaceuticals, after all, have vastly different requirements for a safe environment. Therefore, the FDA instead mandates a broad range of requirements for what constitutes safe storage of pharmaceuticals. The FDA pharmaceutical warehouse requirements are laid out in part 205.50 subchapter C of U.S. Title 21.

FDA requirements for facilities are as follows:

- Size: The FDA requires that pharmaceutical storage facilities be of a size suitable to be adequately cleaned, maintained, and to allow for proper operations. This can be taken to mean that the FDA will frown on cramped facilities in which the lack of space interferes with operations and allows dirt and debris to accumulate. The FDA also requires facilities to have a designated area for quarantining pharmaceuticals whose temperature controls have lapsed, use-by dates have expired, or whose safety is otherwise questionable.

- Environment: The environment should be designed to provide adequate lighting, ventilation, temperature, and humidity control. Temperature and humidity controls are meant to keep any stored pharmaceuticals in an environment that maintains their efficacy. Appropriate manual, electromechanical, or electronic temperature and humidity logs should be utilized to ensure that pharmaceuticals are stored correctly.

- Security: Due to concerns about pharmaceutical theft and diversion, the FDA requires that pharmaceutical warehouses be secured from unauthorized entry, that entry be well controlled, and that these facilities be equipped with alarm systems. They also require that the outside perimeter of the warehouse be well lit.

FDA warehouse requirements for pharmaceuticals are split between maintaining the integrity of the drugs, preventing diversion of pharmaceuticals, and ensuring a safe workplace. In essence, the FDA doesn’t so much mandate CGMPS as provide criteria that warehouses must fulfill when developing their own CGMPS.

Complying with FDA Pharmaceutical Warehouse Requirements

There are so many different types of pharmaceuticals and so many criteria in different fields that an exhaustive discussion of FDA compliance can and does fill several volumes. In short, to be licensed by the FDA as a pharmaceutical warehouse, the facility will need to submit a detailed written plan that offers the following information:

- Lists the pharmaceutical types the warehouse will be handling.

- Explains how the warehouse will store these pharmaceuticals to ensure they remain effective.

- Details the sort of environmental checks that will be performed and how these checks will be recorded.

- Provides a detailed procedure for how pharmaceuticals determined to be unsafe will be disposed of.

It is important to note that the FDA reserves the right to inspect a warehouse at any time to ensure that the facility’s operators are following submitted and approved procedures. If the warehouse is found to be out of compliance, the FDA can levy fines or even revoke the facility’s permission to deal in certain types of pharmaceuticals or to work with pharmaceuticals at all.

Fortunately, complying with FDA pharmaceutical warehouse requirements is largely a matter of following common-sense practices and meticulously documenting that those practices have been followed. Technology like warehouse automation makes it easier to follow procedures and document that those procedures have been followed —provided that the automation is backed by the right types of equipment.

How Plastic Pallets Help Companies Meet FDA Requirements

Many FDA pharmaceutical warehouse requirements essentially come down to traceability. This should come as no surprise, since the Drug Supply Chain Security Act (DSCSA) mandates traceability. And the FDA recently announced that beginning in November of 2023, they will launch an enhanced version of the serialization system currently in place. The emphasis of this act is to prevent the diversion of pharmaceuticals into illegal markets for illicit use by mandating a serialized tracking number be placed on drug packaging and carefully recorded.

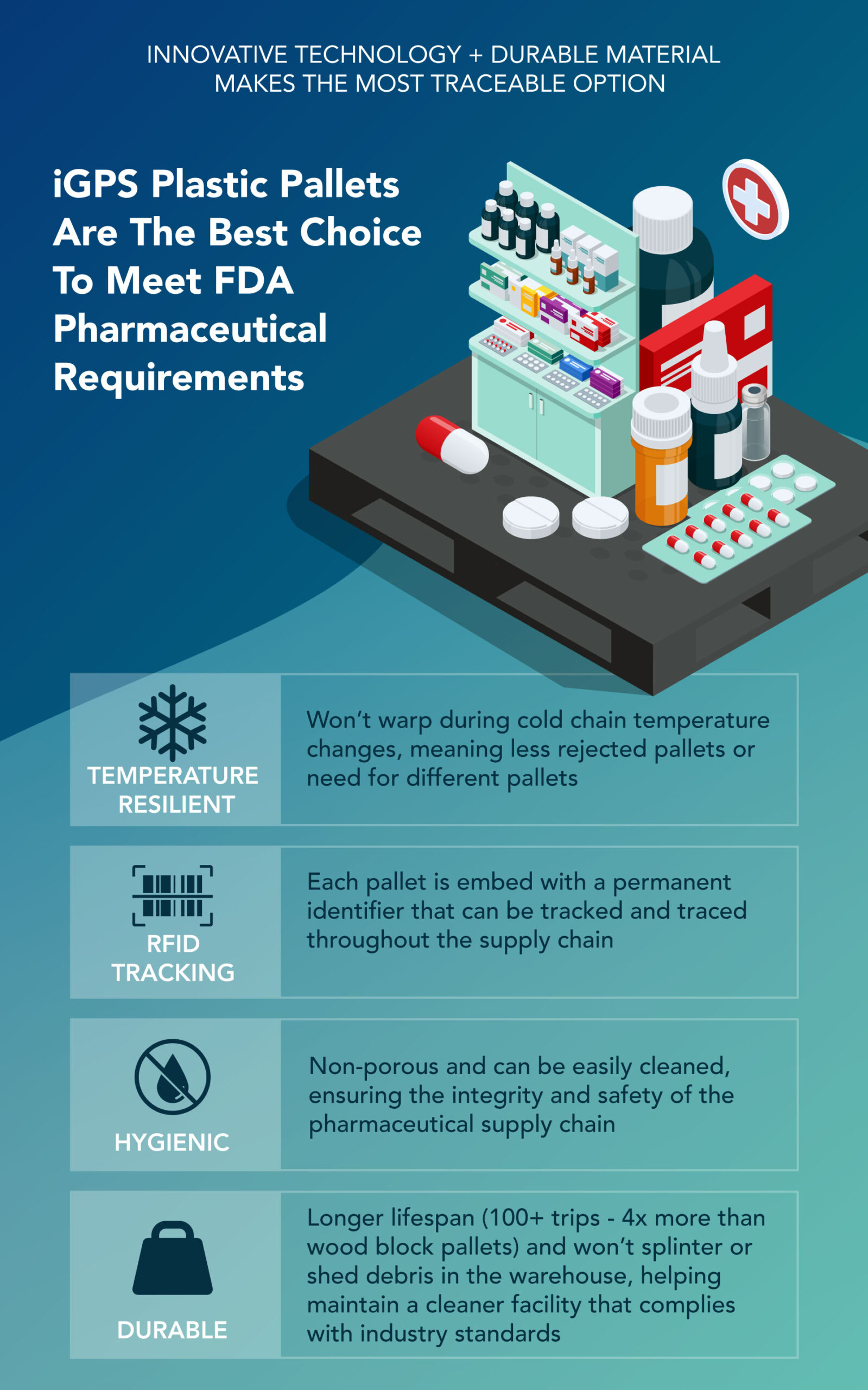

Plastic pallets can facilitate this traceability. They can be embedded with a serialized identifier number that provides a way to track the storage conditions of pharmaceuticals at the load unit level. This adds an additional level of traceability and makes it easier to be sure that critical procedures in the cold chain management of pharmaceuticals, such as temperature checks, were followed. This permanent traceability is made possible by the long lifespan and durability of plastic pallets, which makes it cost-effective to embed an identifier in each pallet and make that identifier readable through Radio Frequency Identification (RFID). This is in stark contrast to wood pallets, whose short lifespan and frequent repairs mean a permanent identifier or pallet license typically isn’t practical.

The durability of plastic pallets also ensures that facilities stay clean by eliminating the splinters and debris that are often shed by wood pallets. This helps companies maintain a clean facility that complies with warehousing CGMPS. Plastic pallets are also non-porous and can be easily cleaned, making them one of the best ways to meet FDA pharmaceutical warehouse requirements designed to ensure the integrity and safety of the pharmaceutical supply chain.

Companies striving to comply with FDA warehouse requirements for pharma should consider iGPS plastic pallets for all their shipping needs. Our lightweight, recyclable plastic pallets incorporate RFID technology, making them traceable throughout a supply chain. For more information, contact us at 1-800-884-0225, email a specialist at [email protected], or visit our contact page.